Intelligent pneumatic flanging mechanism

A flanging and intelligent technology, applied in the field of packaging can manufacturing, can solve problems such as unfavorable manufacturing and complex structure, and achieve the effects of ensuring stable and reliable manufacturing, demoulding, and fast and reliable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

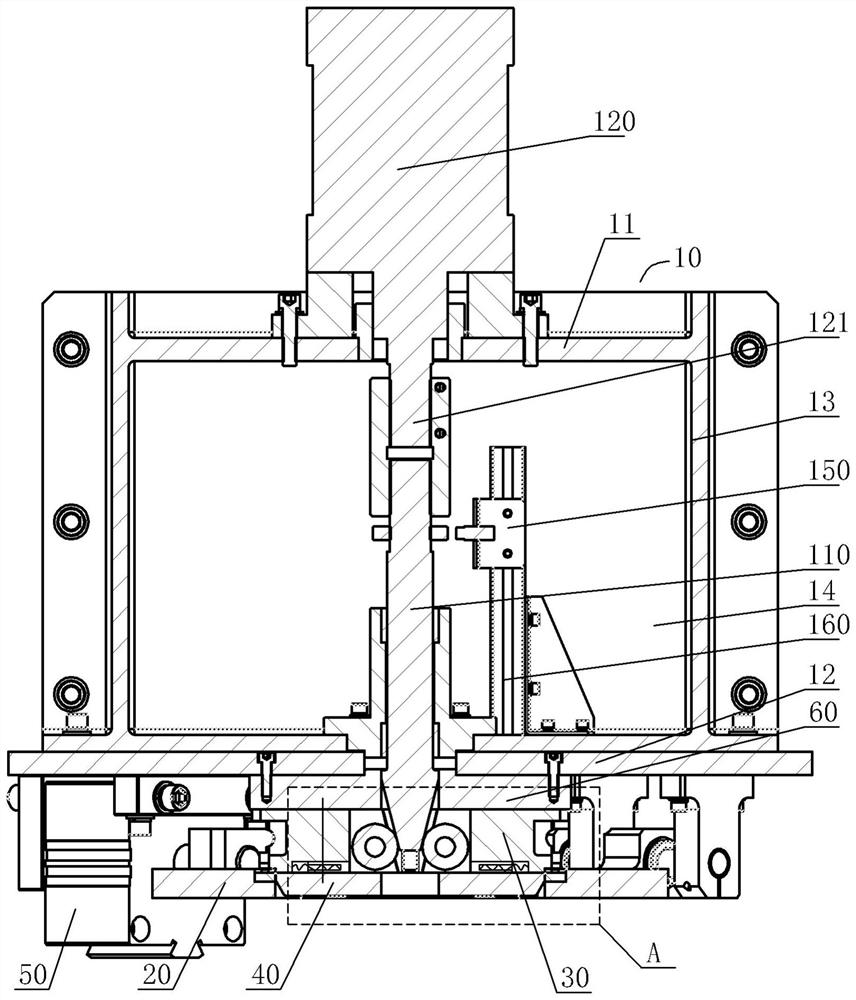

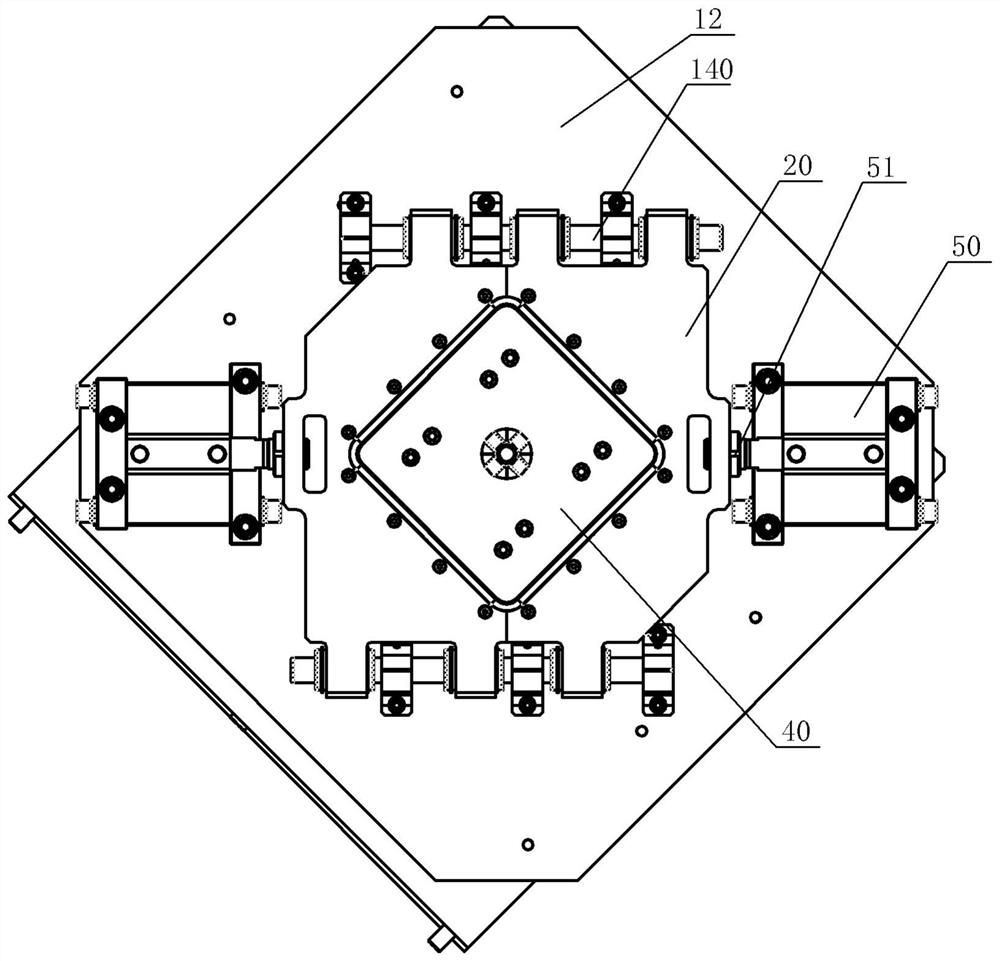

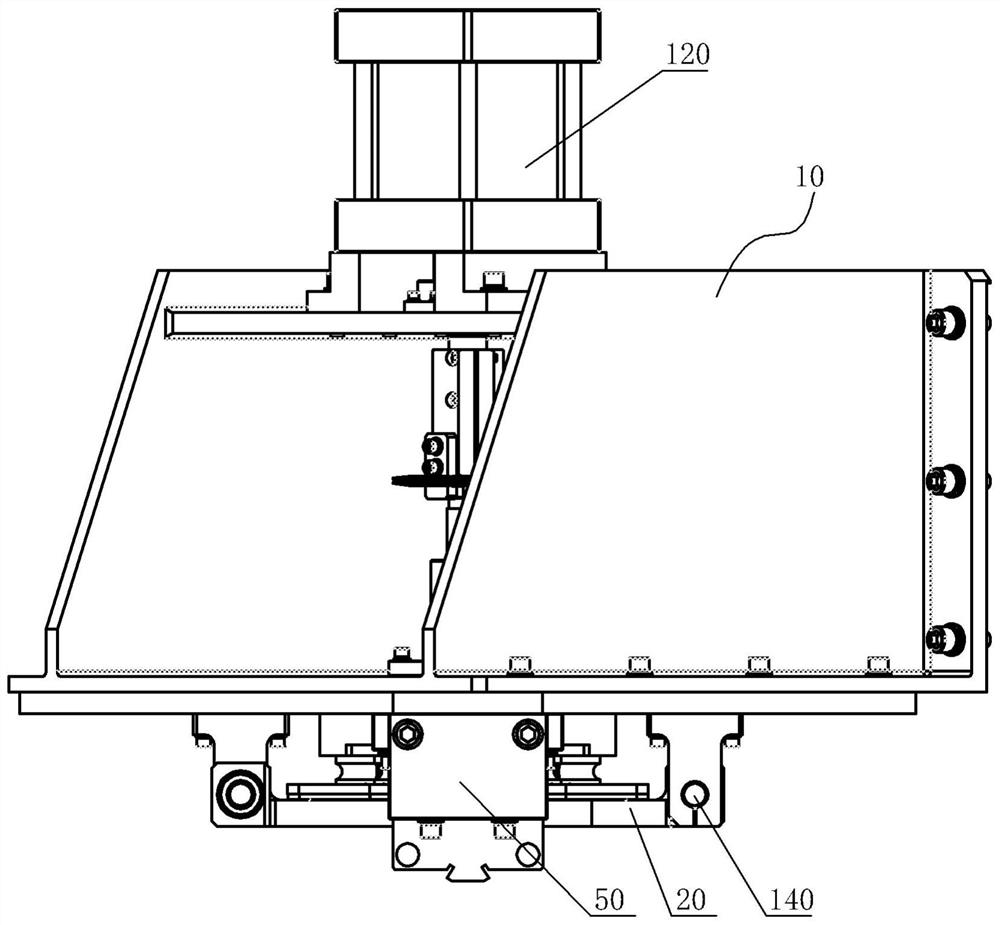

[0026] An intelligent pneumatic flanging mechanism, see Figure 1-Figure 4 , which includes:

[0027] The flange frame 10 includes an upper plate 11, a lower plate 12 and two side vertical plates 13, the upper plate 11 is connected to the lower plate 12 through the two side vertical plates 13, and a cavity 14 is formed in the two side vertical plates 13;

[0028] Two flanging profiling 20;

[0029] Flange inner mold 30;

[0030] guide block 40;

[0031] The lower surface on both sides of one of the diagonal lines of the lower plate 11 is respectively fixed with a master cylinder 50, and the piston ends 51 of the two master cylinders 50 are arranged opposite to each other, and each piston end 51 is fixedly connected with a flanging leaner on the corresponding side. Die 20, the upper surface of the inner end of the two flanging molds 20 is profilingly set in the flanging shape of the product;

[0032] The central position of the lower plate 11 is connected to the guide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com