Rib carving structure for tank body

A rib structure and tank body technology, which is applied in applications, household appliances, and other household appliances, can solve problems such as unstable working conditions, the tank body is separated from the work station, and the ribbed structure is complicated, so as to achieve stable and reliable separation, and structural simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

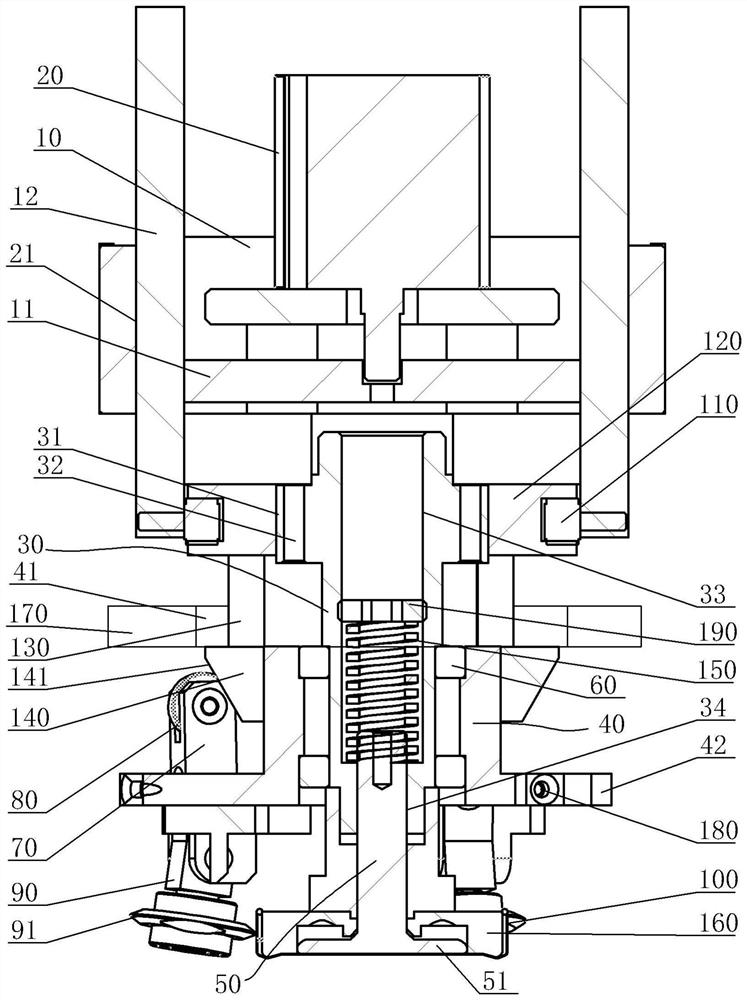

[0024] A ribbed structure for tanks, see figure 1 , which includes an upper fixed plate 10, a vertical lifting cylinder 20, a vertical sleeve 30, a turntable 40, and a reset rod 50;

[0025] The central axis of the vertical sleeve 30 is a hollow structure;

[0026] The turntable 40 includes an upper transmission disk 41 and a lower rotation disk 42;

[0027] The bottom of the reset lever 50 is provided with a press-attach plate 51;

[0028] The outer circumference of the middle part in the height direction of the vertical sleeve 30 is provided with a turntable 40 through a double bearing structure 60. The outer ring of the lower turntable 42 is covered with a number of transmission seats 70, and the drive seats 70 are pivotally connected to the corresponding parts of the lower turntable 42. Circumferential position, and the upper part of the transmission seat 70 is provided with a roller bearing 80, the lower part of the transmission seat 70 is provided with a ribbed roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com