Device for producing container products consisting of plastic materials

A technology of raw materials and plastics, applied in the field of molding devices, can solve the problems of production speed limitation, etc., and achieve the effect of reducing the size of the structure, continuous production, and easy disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

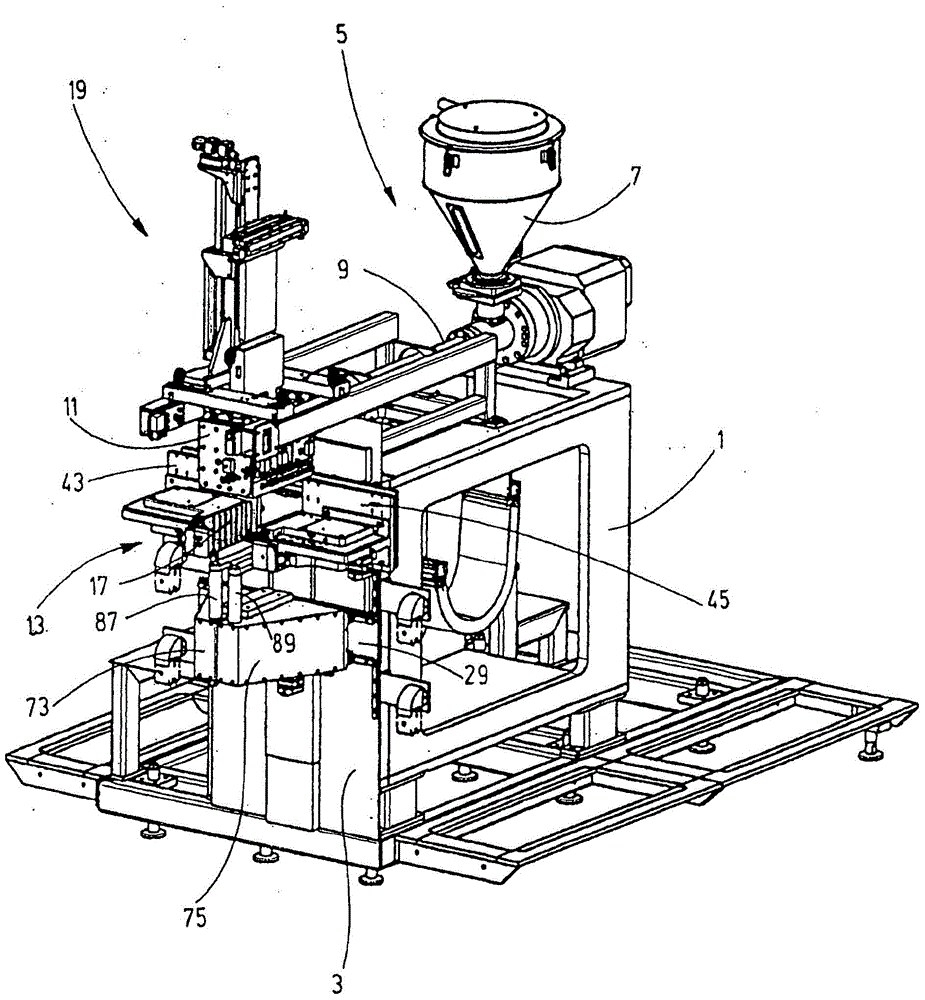

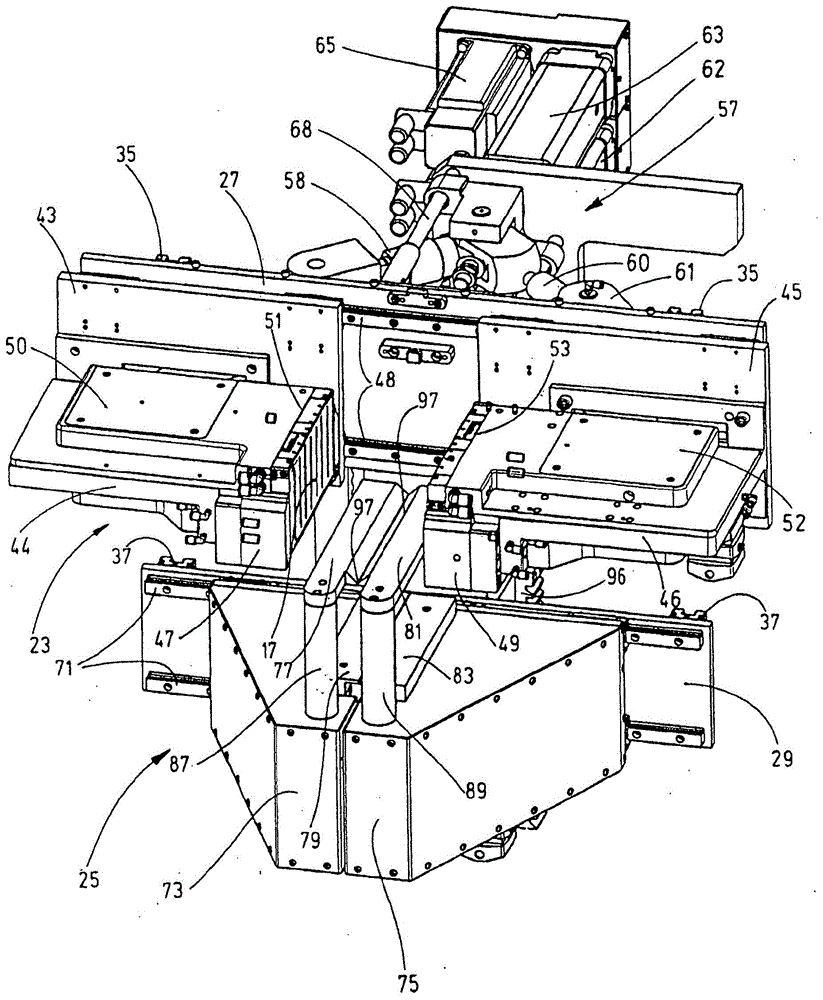

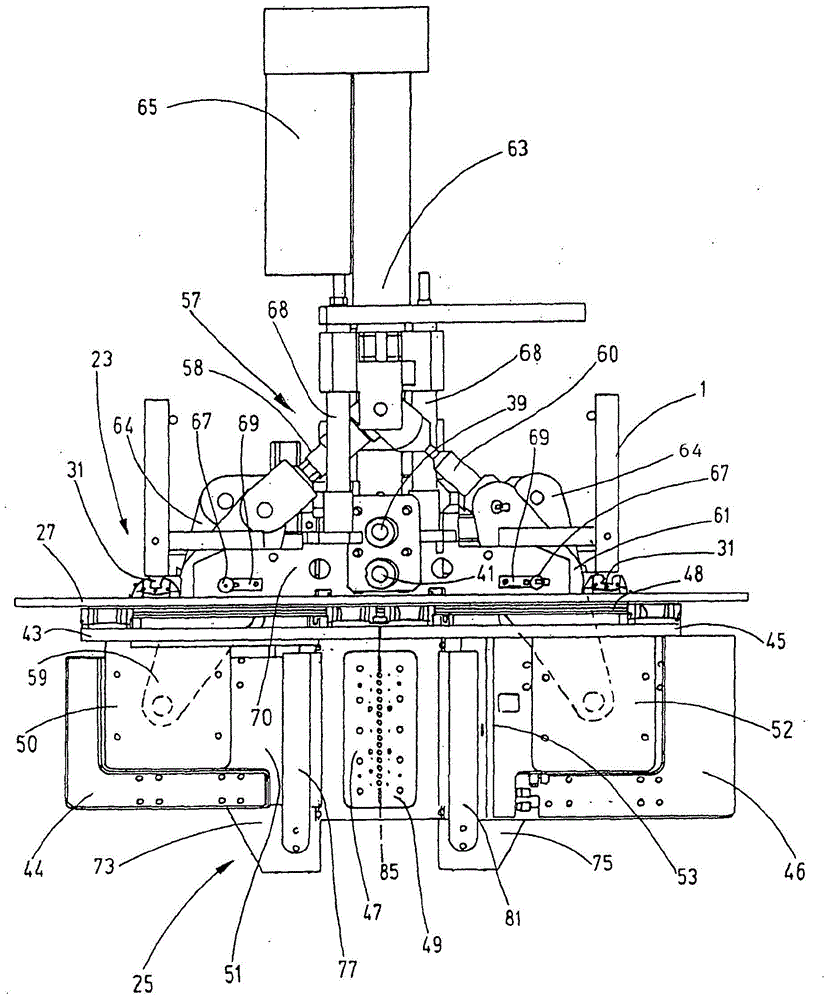

[0030] In a general view showing an embodiment of the device according to the invention in a simplified view figure 1The central device frame is referenced 1 and has a rectangular box shape with a front side 3 extending in a vertical plane. On the box-shaped upper side of the frame 1 there is provided a pressing device generally designated 5 which is constructed according to the relevant prior art and has a feed funnel 7 for plastic granules and a motor-driven, The extrusion screw unit 9 feeds the plasticized plastic material to the extrusion head 11 . This extrusion head is likewise constructed according to the prior art and extrudes the heated, plasticized plastic material in the form of a flat tube over the entire width of the molding device 13 measured along the parting plane. Extend up. Thus, depending on the configuration of the forming device 13, a single extruded, Figure 5 The profiled tubes, referenced 15 , form a plurality of container articles according to the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com