Cast iron mold with rapid demoulding function

A cast iron mold and demoulding technology, which is applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of high labor intensity of workers and damage to cast iron molds, and achieve low labor intensity of workers, fast demoulding speed, and easy demoulding reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

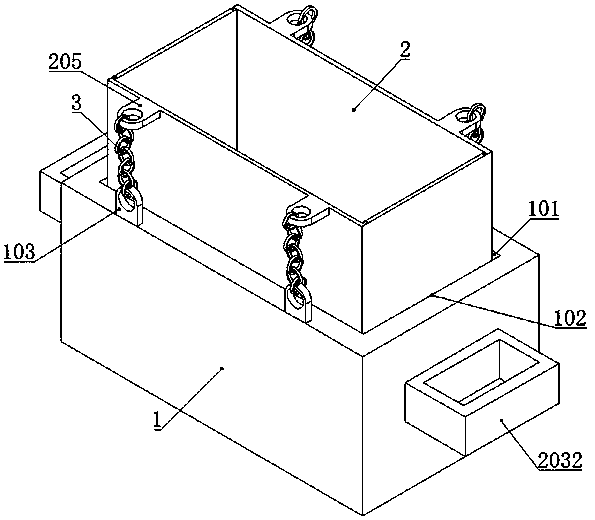

[0022] Such as figure 1 As shown, a cast iron mold with quick release function includes a base mold 1 and a casting mold 2.

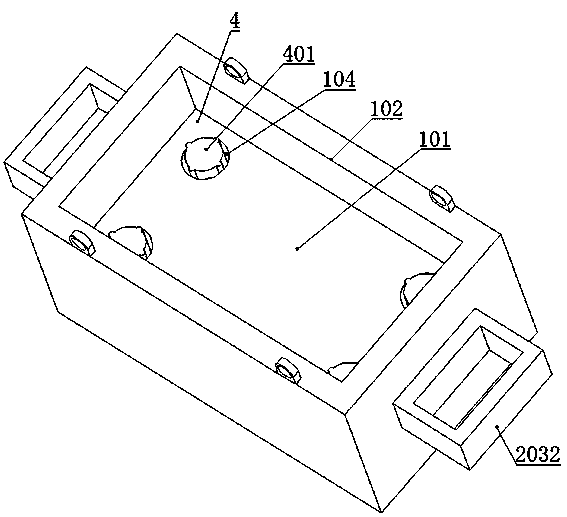

[0023] Such as figure 2 As shown, the base mold 1 is a box structure, which has a mold cavity 101 and an upper open die opening 102 .

[0024] exist figure 1 Among them, the casting mold 2 is movably set in the mold cavity 101 of the base mold 1 through the die opening 102 of the base mold 1 .

[0025] In order to facilitate the casting mold 2 from the mold cavity 101 of the base mold 1, the casting mold 2 and the mold cavity 101 of the base mold 1 are fitted with a gap, and the gap difference is preferably in the range of 2 mm to 5 mm. In this embodiment, the gap difference between the mold cavity 101 of the casting mold 2 and the base mold 1 is controlled at 3.5 mm.

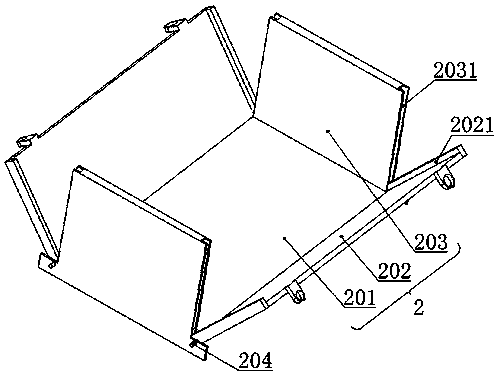

[0026] Such as image 3 As shown, the casting mold 2 includes a bottom plate 201 , two side templates 202 and two end templates 203 . Wherein, the end templates 203 are symmetrica...

Embodiment 2

[0038] The difference from Example 1 is that, as Figure 6 As shown, the ejector device 4 includes at least one cylinder 404, and at least one accommodating chamber 106 is provided corresponding to the cylinder 404 on the bottom of the inner mold of the base mold 1, and the cylinder 404 is correspondingly fixed in the accommodating chamber 106, and the piston rod of the cylinder 404 moves against Top on the bottom plate 201 of the mold 2. The quantity of air cylinder 404 is also set according to the volume of casting mold 2, in the present embodiment, the quantity of air cylinder 404 adopts four, and then the quantity of accommodating chamber 106 is also four, and it is respectively opened in four corners of the inner mold bottom of base mold 1 superior. During application, the intake pipe of the cylinder 404 is connected to the outlet end of the power air source 7 in a conventional loop. When the casting mold 2 and the base mold 1 circulate to the ejection station at the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com