Optical fiber connector

A fiber optic connector and housing technology, applied in the field of optical fiber connectors, can solve the problems of low housing strength and difficult demoulding, and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

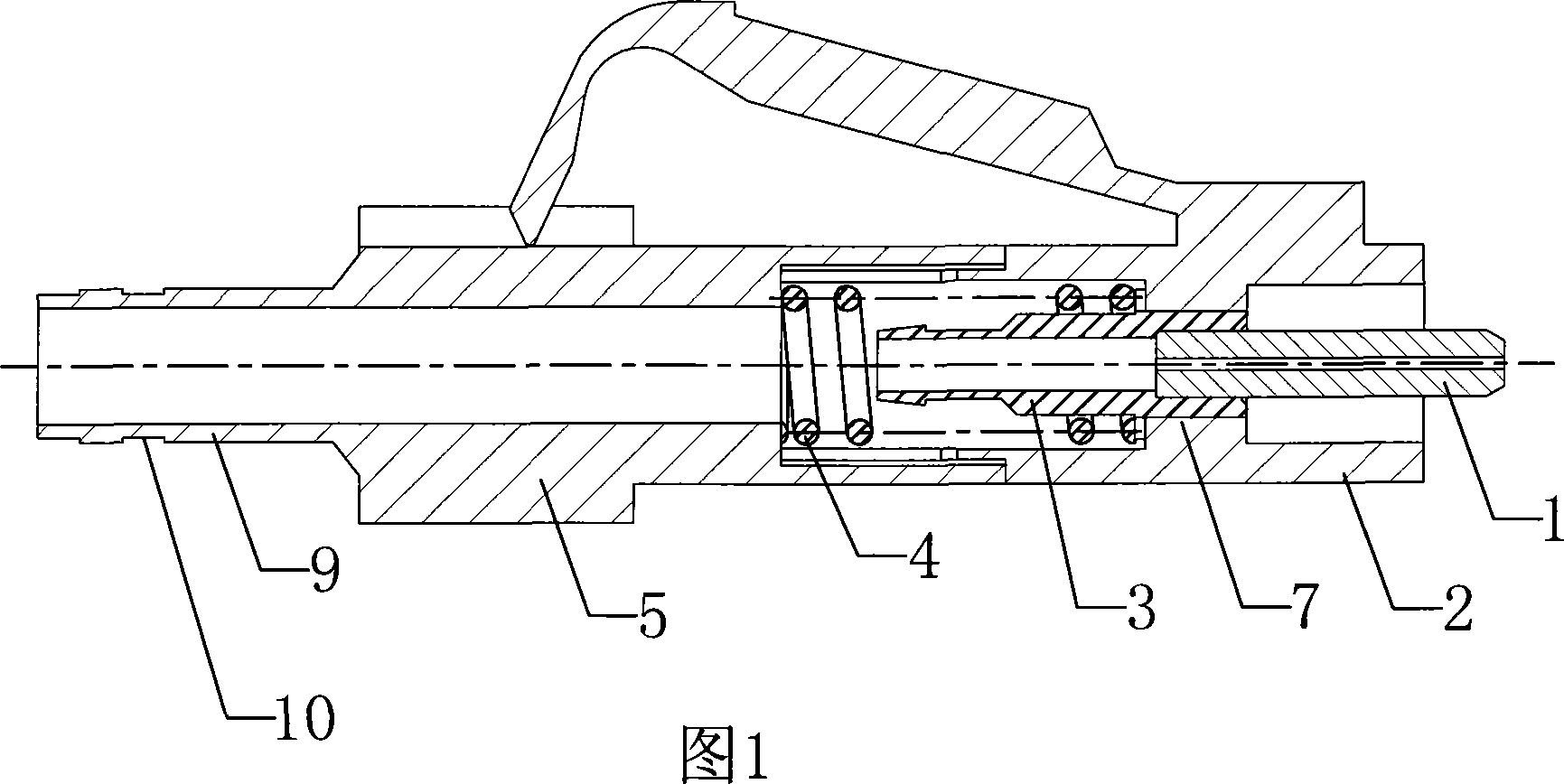

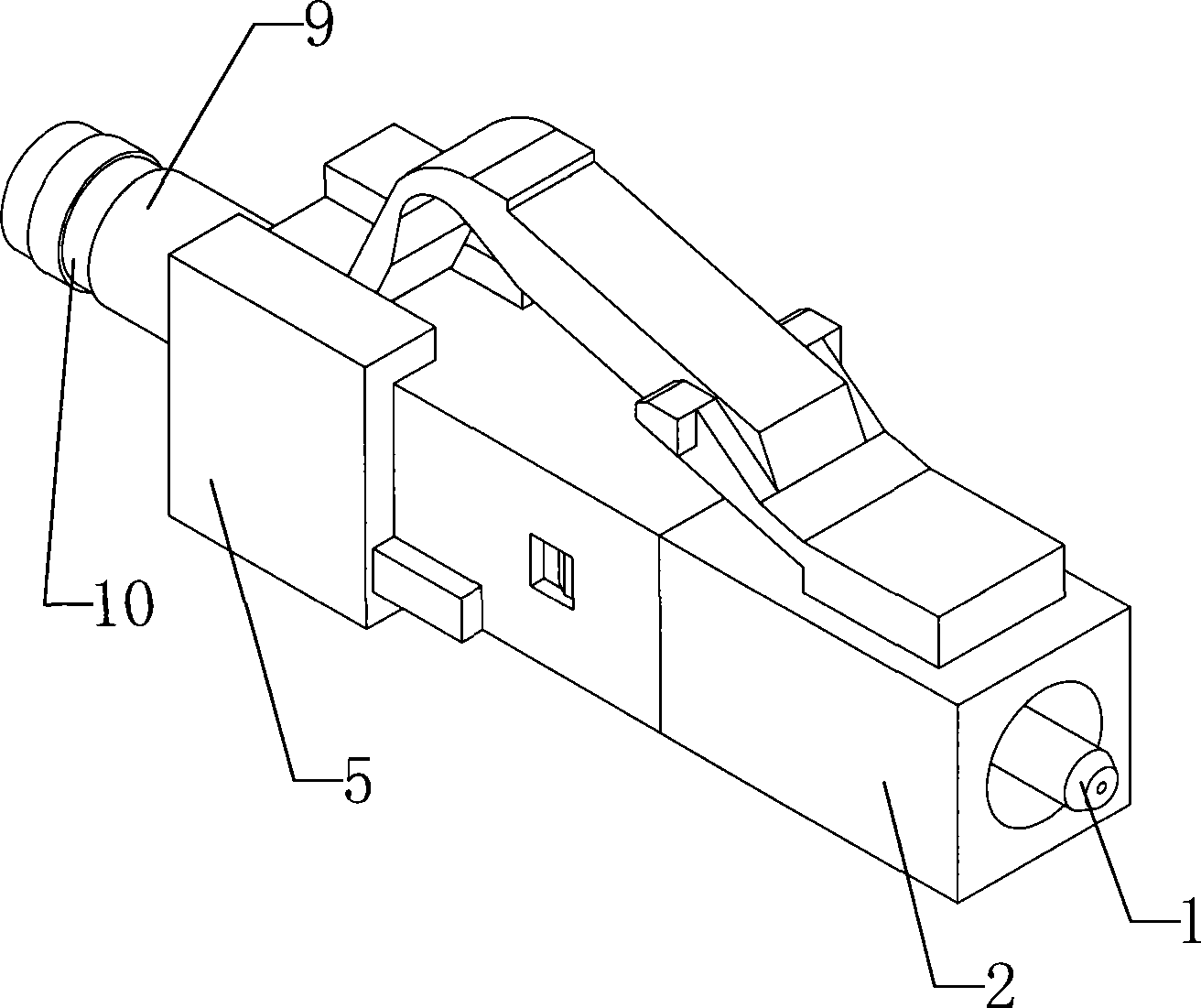

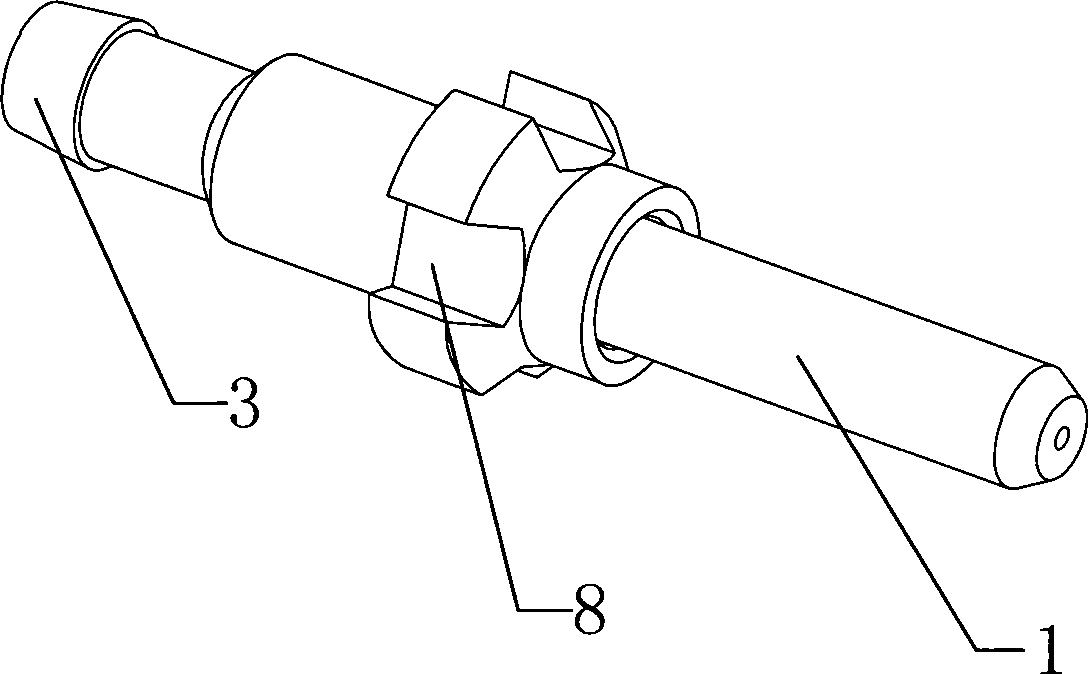

[0014] figure 1, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 An optical fiber connector of the present invention is shown, including a housing, the housing is formed by inserting the front housing 2 and the rear housing 5, the front housing is provided with a pin assembly for anti-rotation, the front housing 2 and the rear housing There is a spring installation chamber at the insertion position of the body 5, and a spring 4 is arranged in the spring installation chamber along the direction of pulling out the optical fiber connector. One end of the spring 4 acts on the rear housing 5, and the other end of the spring 4 acts on the insertion pin. on the component. The above-mentioned contact pin assembly includes a flange 3 and a contact pin 1 that is interference-fitted to the front end of the flange 3. The front face of the flange 3 is a plane, and there are four slave flanges on the circumference of the flange 3. The anti-rotation groove 8 on the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com