Automatic demolding device of frozen noodles production line

An automatic demoulding and production line technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of low production efficiency, deformation of the mold box, and occupying a large area of the workshop, and achieves a small space occupation, compact structure, and reliability. The effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

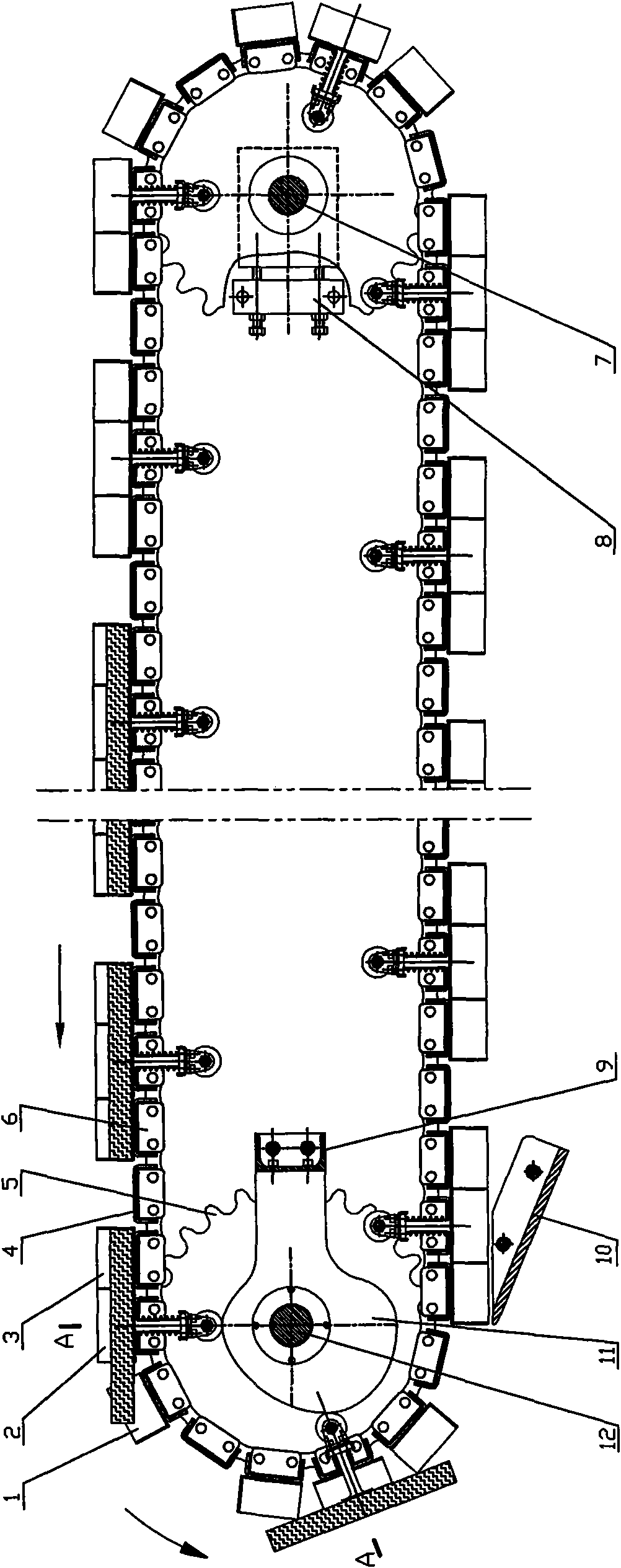

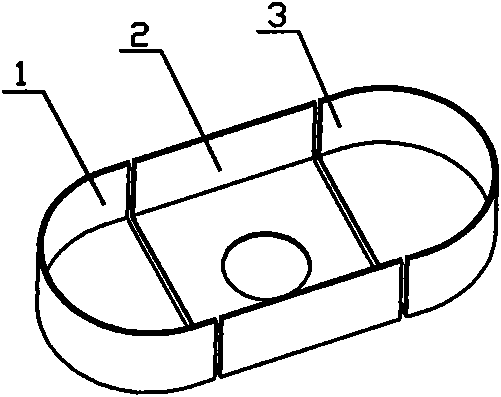

[0016] The automatic demoulding device of the frozen noodle production line of the present invention can select chain conveyors of different widths according to the output of the production line, so that the number of noodle mold boxes in the entire row can be different. Take eight split-type noodle mold boxes installed in each row as an example below to illustrate specific embodiments of the present invention in conjunction with the accompanying drawings.

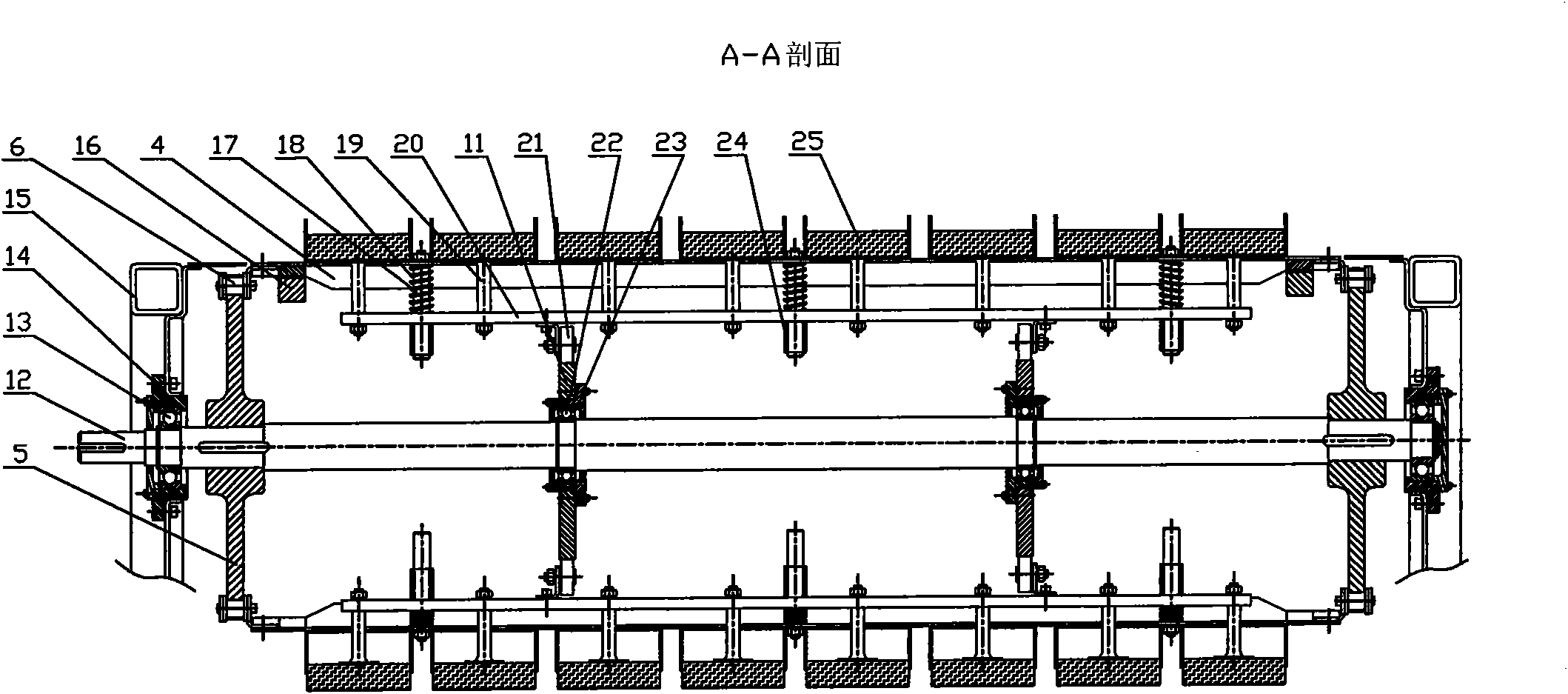

[0017] The structure of the automatic demoulding device of the present embodiment is as follows: figure 1 As shown, the power input of the chain plate conveying mechanism is distributed on the left, and the power is transmitted to the input shaft 12 by the motor, reducer and shaft coupling (not shown in the figure); the tensioning device and the driven shaft 7 are distributed on the right, The chain is moderately tensioned by adjusting the screws on the tensioner. In order to ensure that the chain plate 4 has sufficient r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com