Construction method of pipe gallery construction using formwork trolley

A technology of formwork trolley and construction method, which is applied in earthwork drilling, shaft equipment, shaft lining, etc., can solve the problems of high cost of formwork trolley, increased self-weight of steel truss, and large number of jacks, etc., and achieves enhanced demoulding efficiency, Improving integrity and rapid demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

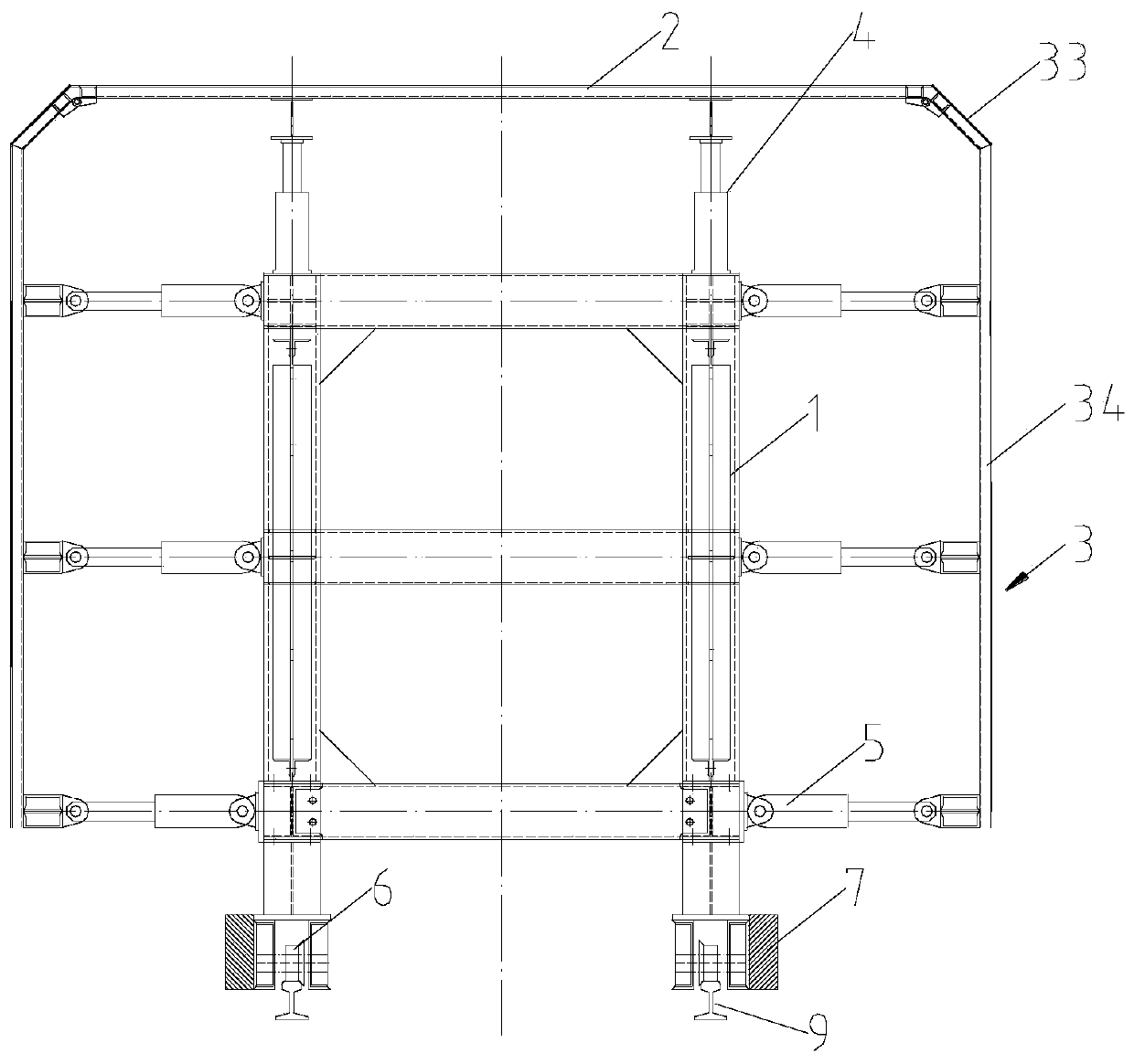

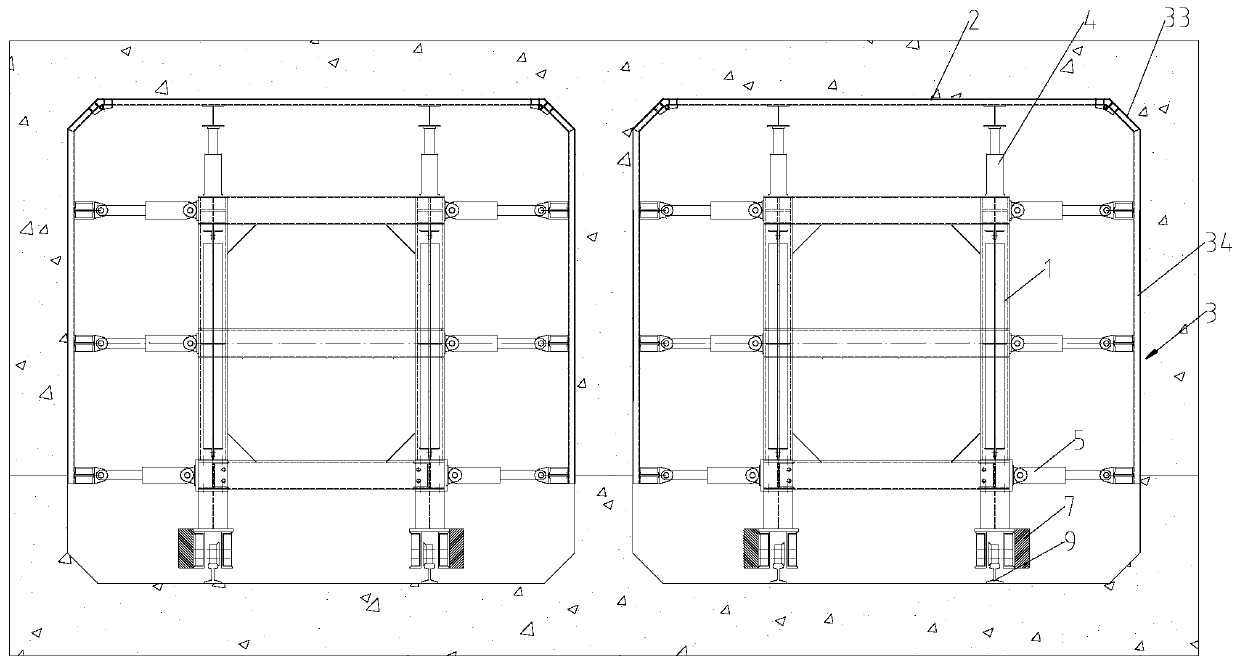

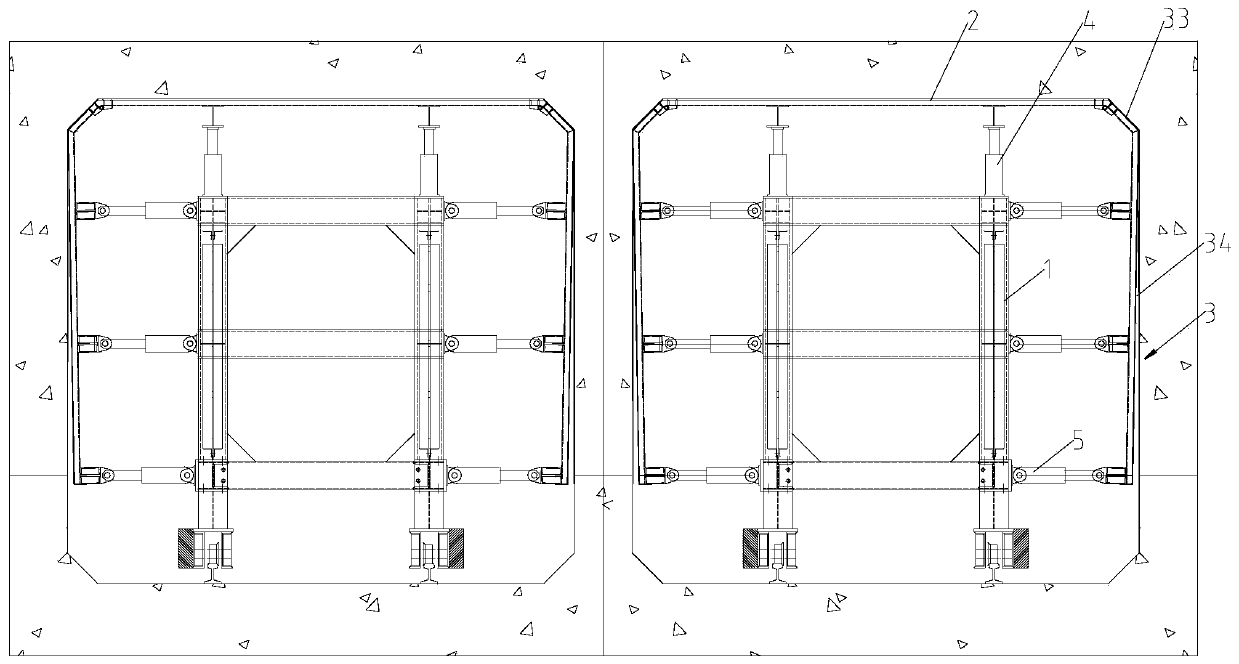

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the construction method disclosed in the present invention is to use a formwork trolley for pipe gallery construction. The formwork trolley is formed by detachable docking of multiple trolley sections; each trolley section includes a steel truss 1 in the middle, The top form 2 arranged above the steel truss 1 and the side forms 3 arranged on both sides of the steel truss 1, the two ends of the top form 2 are hingedly connected with the top ends of the corresponding side forms 3 respectively; The horizontal hydraulic jacks 5 arranged in groups, each horizontal hydraulic jack 5 in the group is vertically arranged along the side form 3, and one end of the horizontal hydraulic jack 5 is connected with the steel truss 1, and the other end is hinged with the side form 3; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com