Cement board demolding device for production

A cement board and demoulding technology, applied in the direction of manufacturing tools, unloading devices, etc., can solve the problems of unbreakable cement board demoulding, cement board damage, etc., and achieve the effect of easy collection, efficient demoulding, and smooth leftward movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

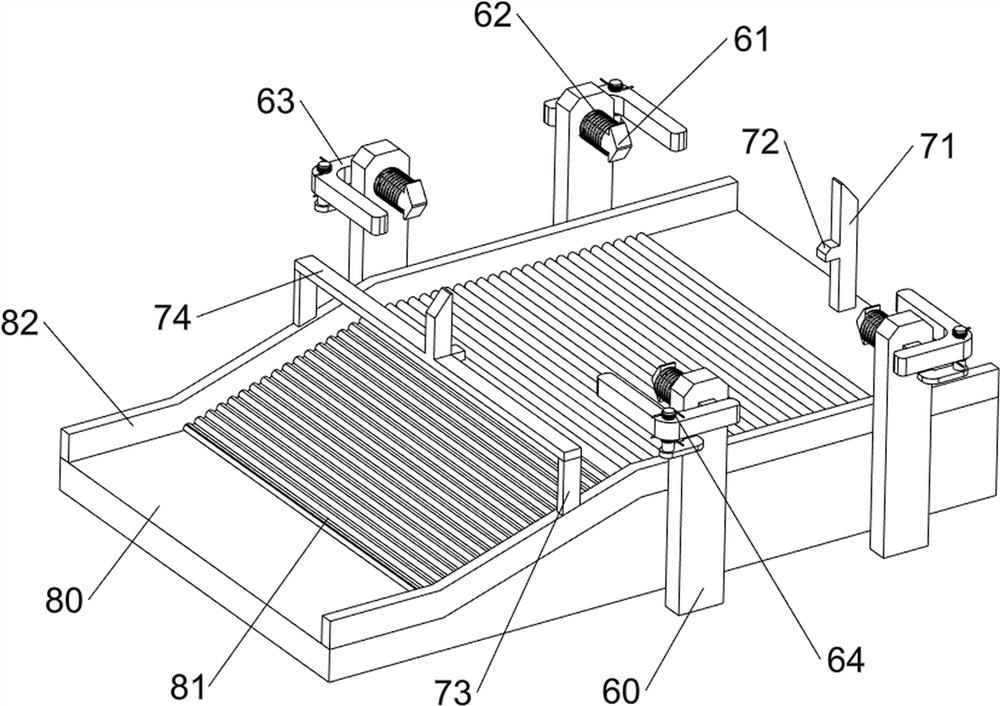

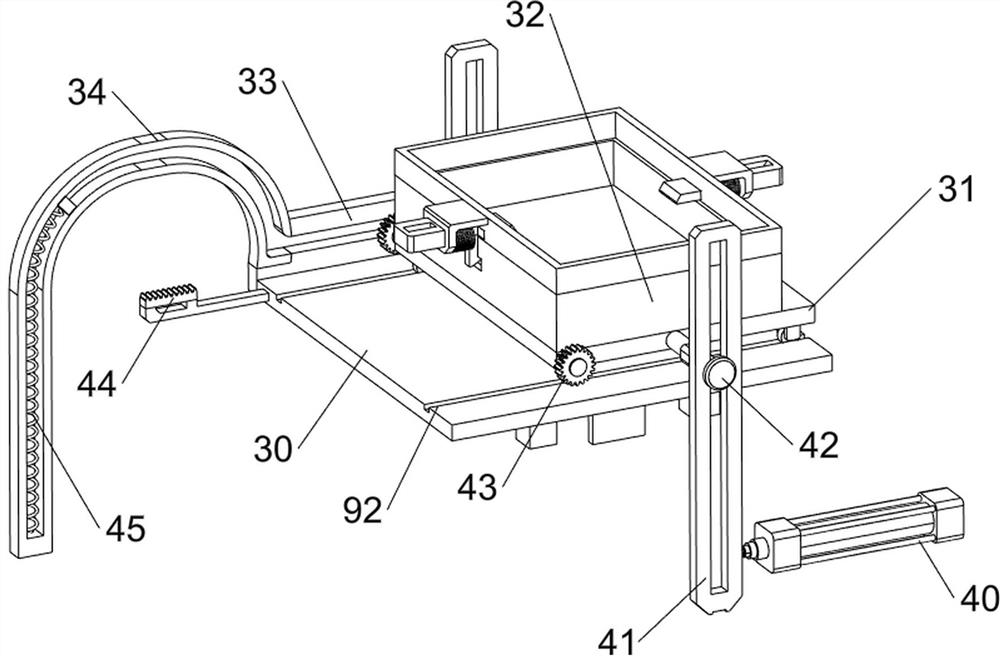

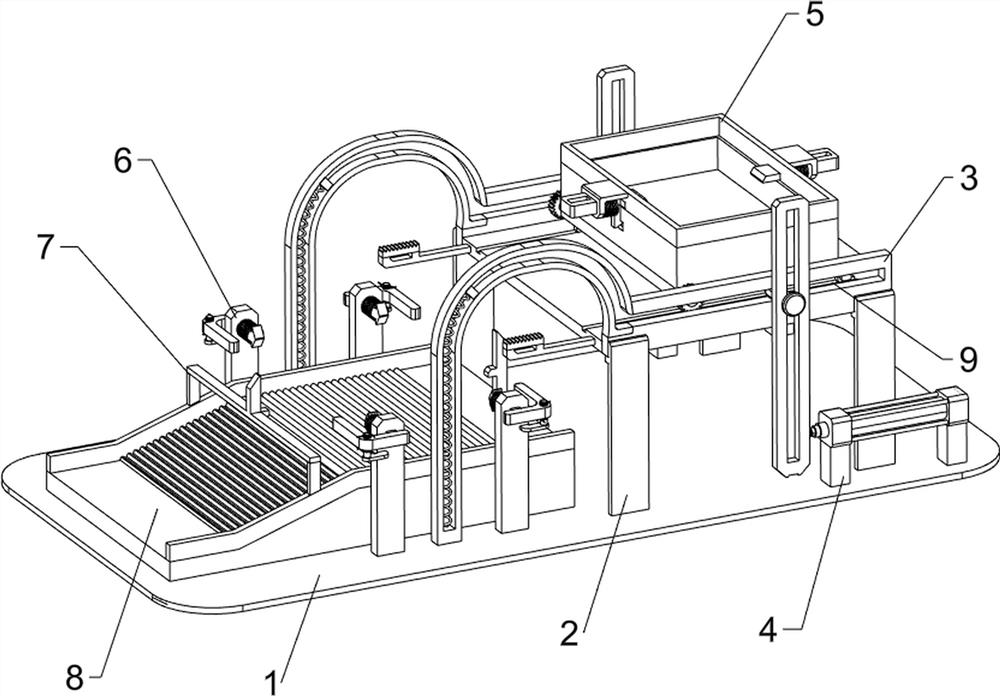

[0026] A kind of demoulding equipment for cement board used in production, such as figure 1 with figure 2 As shown, it includes a base plate 1, a bracket 2, a placement mechanism 3 and a demoulding mechanism 4. The base plate 1 is evenly provided with a bracket 2, a placement mechanism 3 is provided between the brackets 2, and a demoulding mechanism 4 is provided on the base plate 1.

[0027] When people need to use this equipment, first people place the mold with the formed cement board in the placement mechanism 3, and fix the mold, then people can start the demoulding mechanism 4, and the demoulding mechanism 4 operates to drive The placement mechanism 3 moves to the left, and the placement mechanism 3 drives the cement board and the mold to move to the left, and then through the cooperation between the 4 parts of the demoulding mechanism, the rotation of the placement mechanism 3 is realized, and then the cement board and the mold are rotated to the left. After the cemen...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it also includes clamping mechanism 5, clamping mechanism 5 includes isolation frame 50, mounting plate 51, stopper 52, clamping rod 54 and first spring 55, is provided with isolation frame 50 on the mold cover 32, isolation frame 50 A mounting plate 51 is arranged symmetrically on the top, and a stopper 52 is slidingly provided between the mounting plate 51 and the isolation frame 50. The mold cover 32 is symmetrically provided with a slot 53, and the stopper 52 is provided with a clamping rod 54. The clamping rod 54 Engaged with the clamping slot 53 , the first spring 55 is sleeved on the stopper 52 , and the first spring 55 is connected with the mounting plate 51 and the clamping rod 54 .

[0033]When people need to place the mold with cement board in the mold cover 32, first people pull the clamping rod 54 outward, the first spring 55 is compressed, and the clamping rod 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com