Multiple linkage reciprocating capsule stripping machine

A demoulding machine and capsule technology, which is applied in the field of multiple linkage reciprocating capsule demoulding machines, can solve the problems of low demoulding efficiency, unfavorable large-scale production line supporting application, and occupying a lot of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

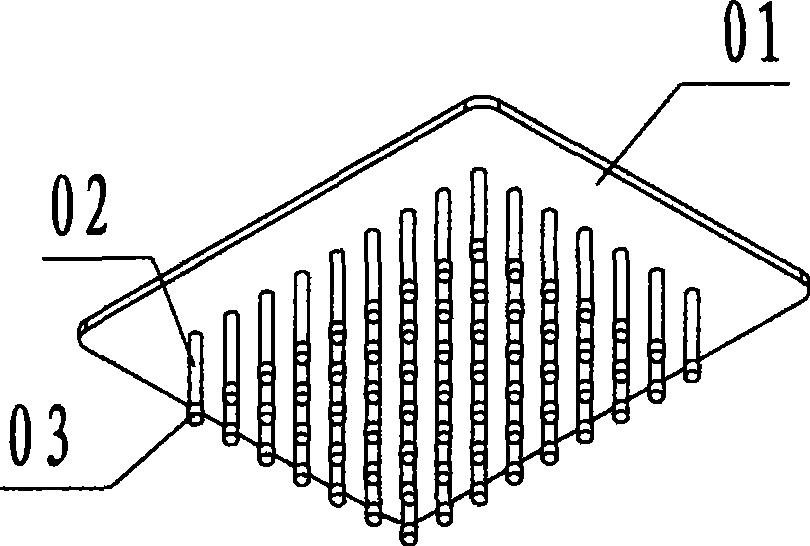

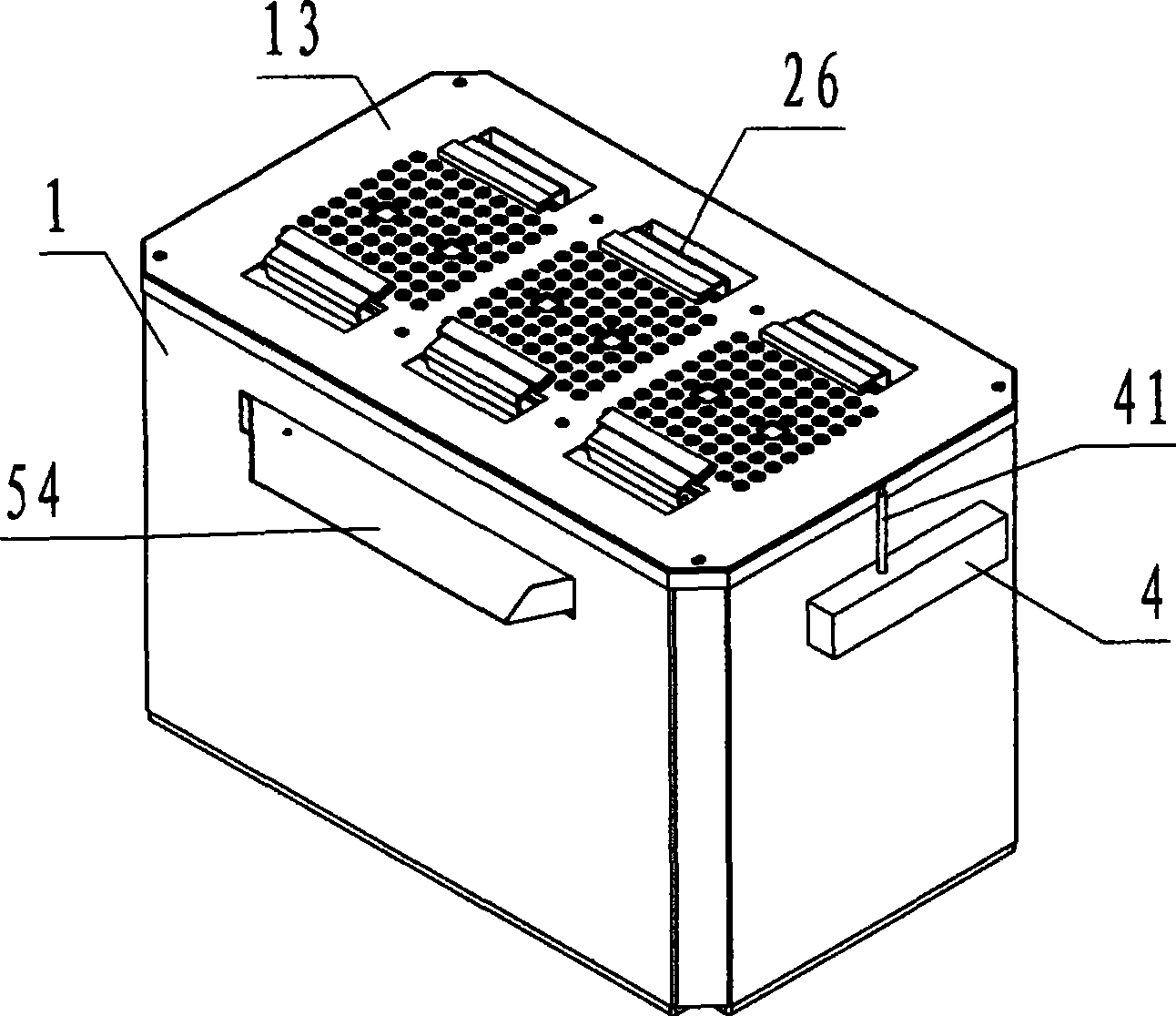

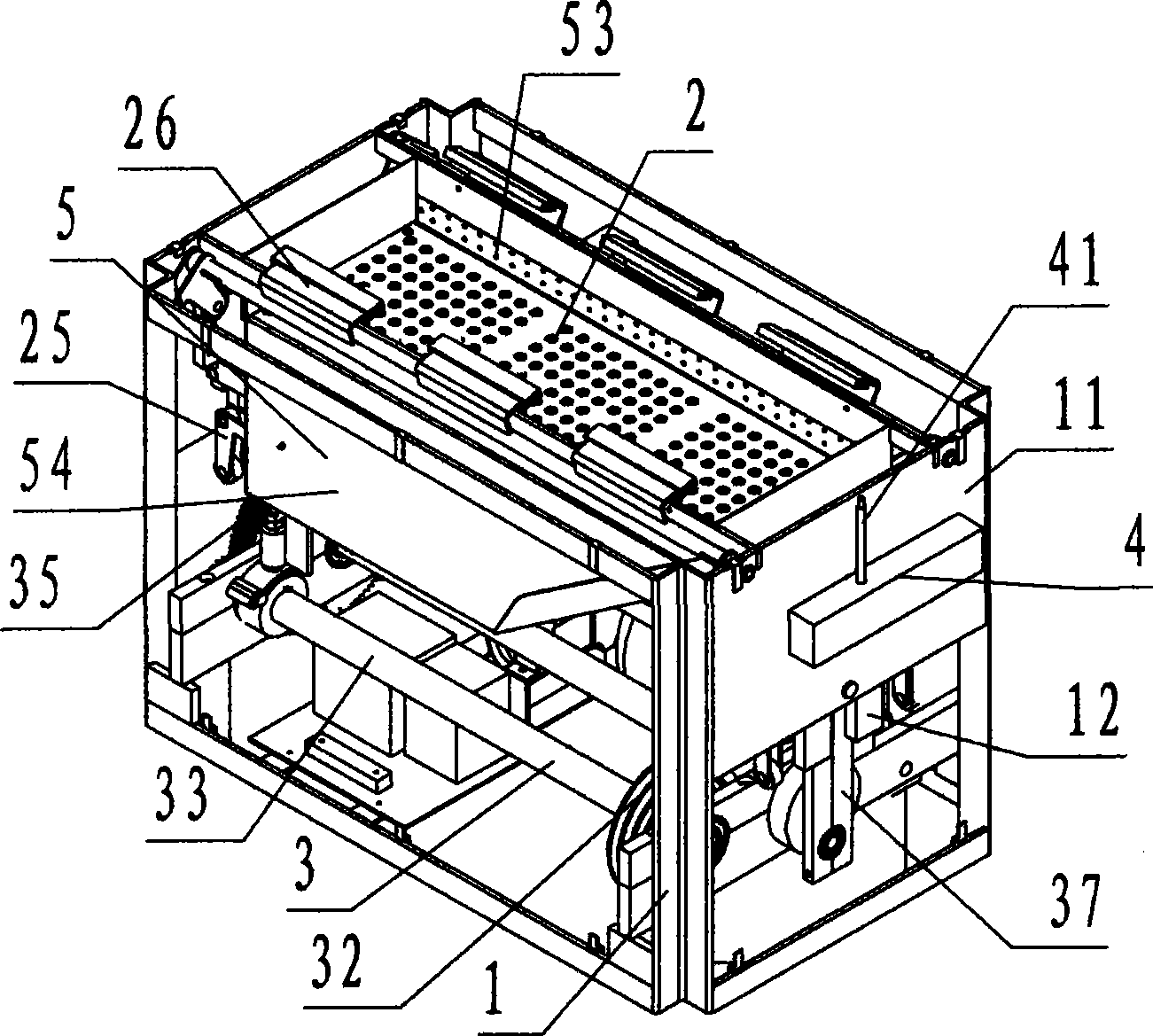

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9, Figure 10, Figure 11 , a multi-link reciprocating capsule demoulding machine of the present invention includes a fuselage 1, a clamping system 2, a power transmission system 3, an electric control system 4, and a collection system 5, wherein: the fuselage 1 includes a shell, The wall board 11, the guide rail slide board 12, the rectangular supporting frame components carrying the various systems of the capsule demoulding machine, the wall board and the guide rail, and the top cover 13 of the shell are provided with multiple groups of holes adapted to the die head of the standard capsule formwork matrix and positioning holes, the wallboard 11 is fixed on the two sides of the short side of the fuselage 1, the guide rail slide plate 12 is located on the inner sidewall of the wallboard 11, and its vertical guide rail is connected with the bearing fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com