Concrete member manufacturing molding box

A technology for concrete and components, applied in the field of manufacturing track slabs, concrete sleepers or trapezoidal sleepers, can solve the problems of difficult demoulding, unable to change the position of the sleeper shoulder, damage to the box, etc., and achieve high-efficiency demoulding and simple washing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

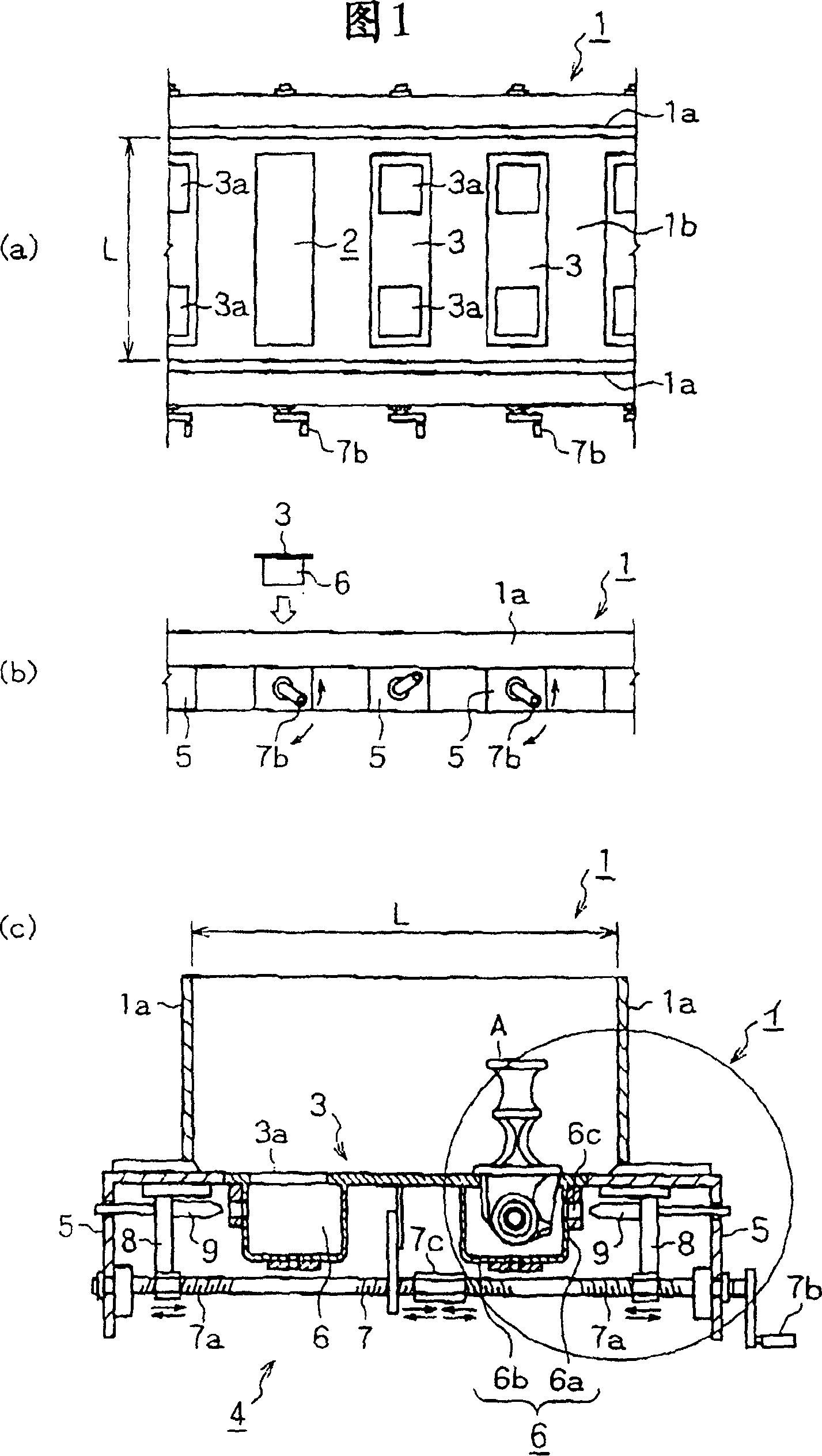

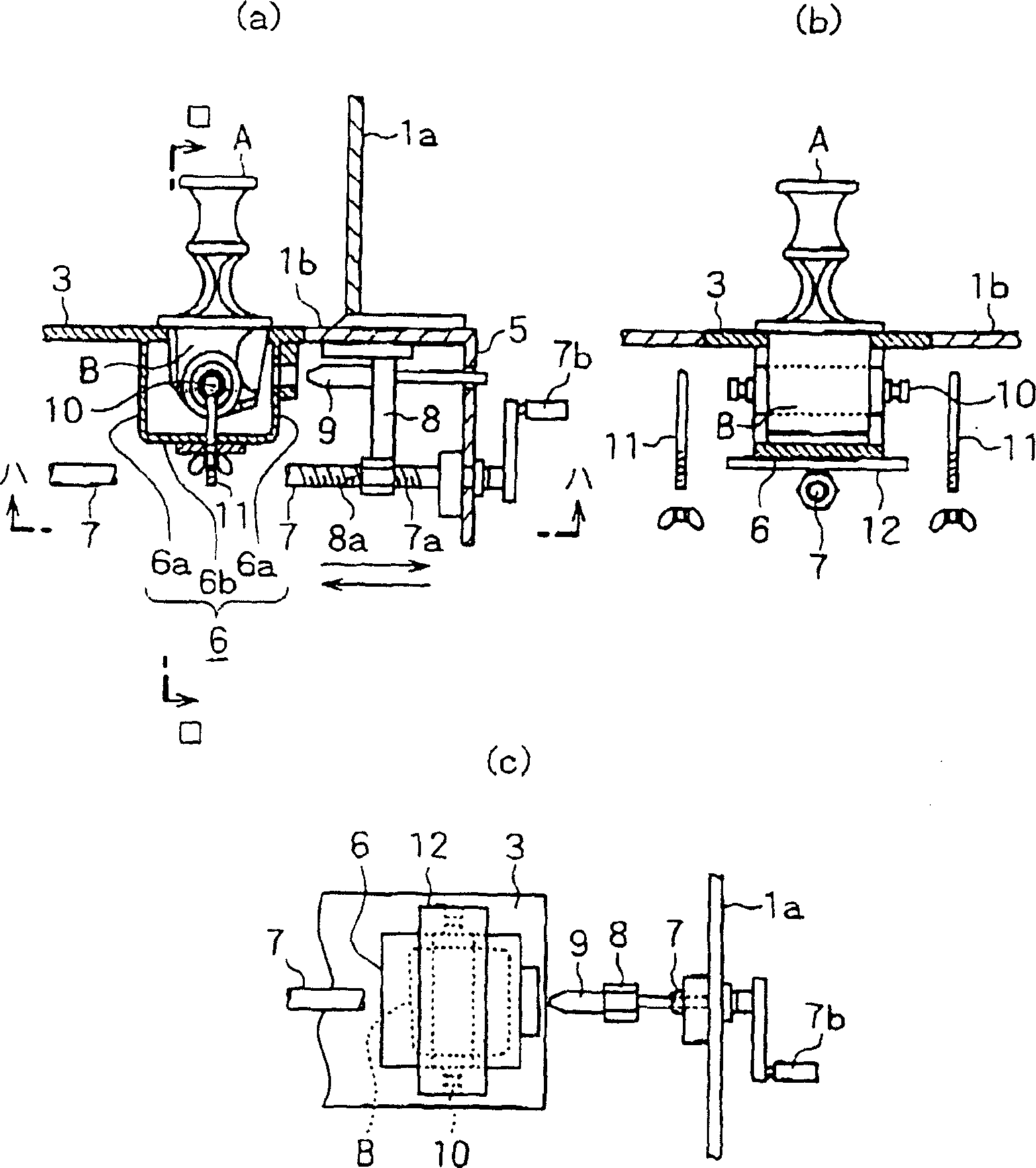

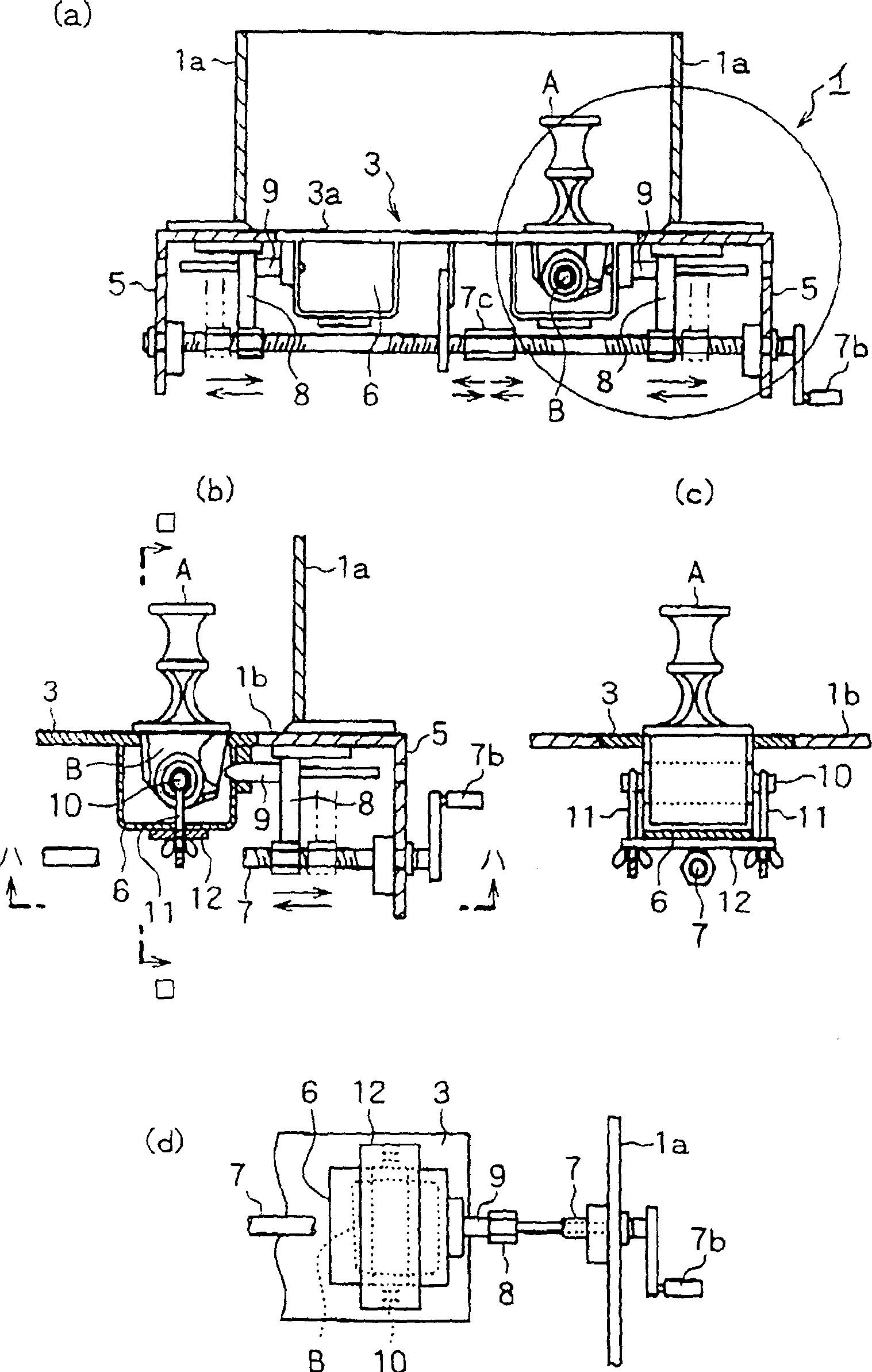

[0026] Figure 1~ Figure 4 An example of a ladder-shaped sleeper molding box (hereinafter referred to as "box") is shown. In the figure, the box main body 1 opens directly above and forms a long and thin box in one direction (for example, the left and right directions in Fig. 1(a)) In particular, the side plate portions 1a and 1a on both sides are installed so that they can slide freely in the out-of-plane direction (for example, the up-and-down direction in FIG.

[0027] In addition, in the bottom plate portion 1b of the molded box main body 1, there are predetermined intervals in the longitudinal direction of the side plate portion 1a (for example, the left and right direction in FIG. The rectangular opening 2 is elongated in the outward direction), and the bottom-shaped box 3 is detachably fixed to each opening 2 by the holding mechanism 4 provided on the lower side of the bottom plate 1b.

[0028] In addition, leg portions 5, 5 are vertically provided on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com