Novel ball socket structure capable of facilitating demolding of ball press machine

A ball pressing machine and ball socket technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as difficult demoulding, achieve efficient demoulding, improve versatility, and expand adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

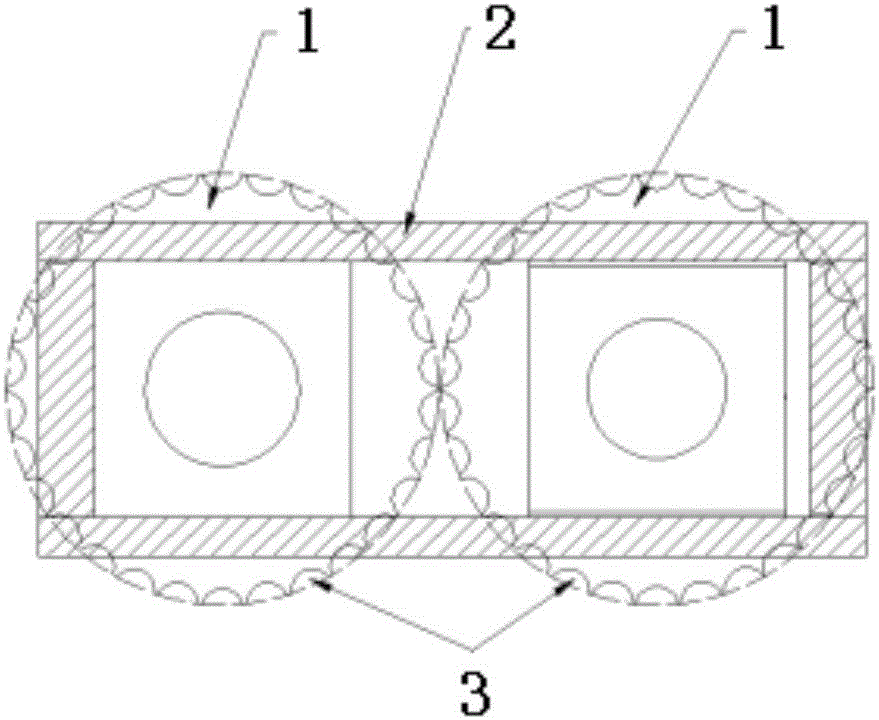

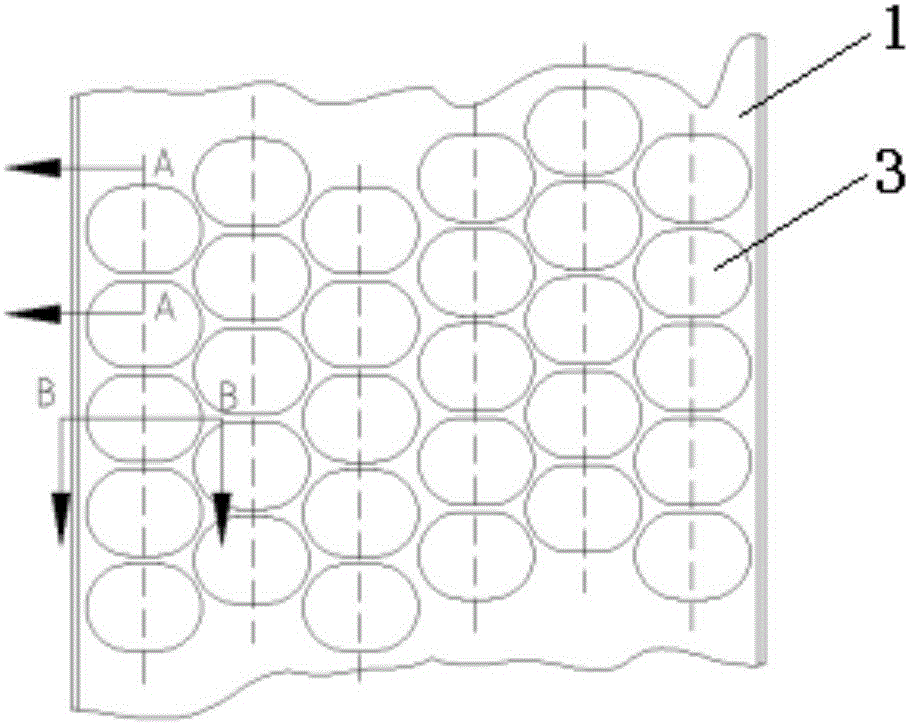

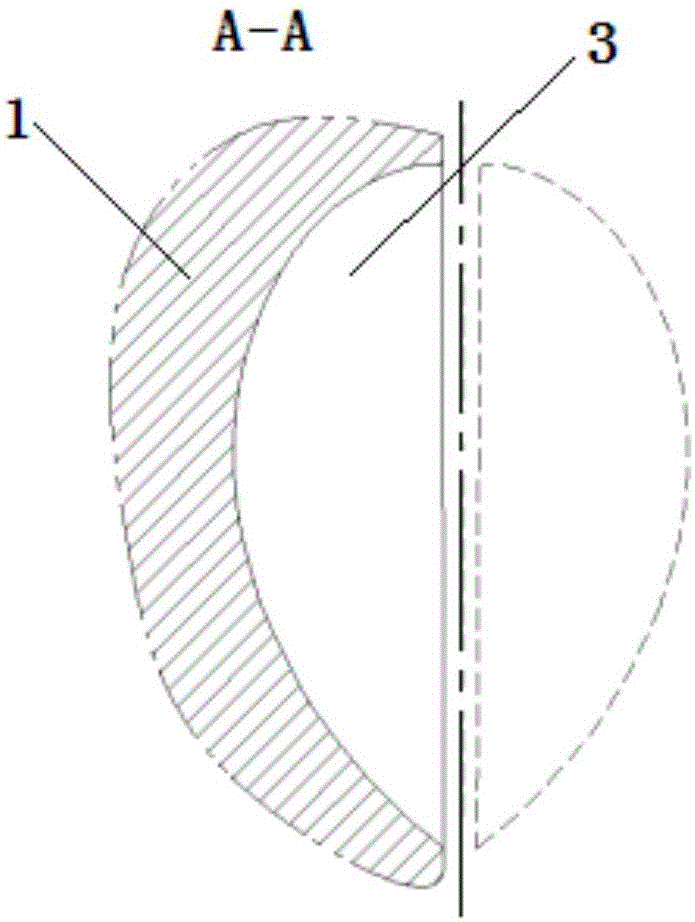

[0012] see Figure 1-Figure 4 , the present invention optimizes and improves the depth direction of the ball socket 3 on the basis of the oblong ball socket on the roll surface of the pressure roller 1 (two pressure rollers 1 are rotatably mounted on the frame 2) of the original ball pressing machine, The involute is used as the depth curve of the ball socket 3, and the diameter of the base circle is set to 7.6-8mm according to the size of the currently used ball to form the shape of an inverted water drop. The recommended size of the ball socket 3 is: the length direction (ie the axial direction of the pressure roller 1) is 32-42mm, the width is 25-30mm, and the depth is 6-15mm. The advantage brought by this is that once the pellet (material to be processed) and the ball socket 3 slide relative to each other, the surface of the pellet and the surface of the ball socket 3 will be separated, and the relative sliding friction of the pellet during demoulding will be reduced to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com