Capsule detachment conjoined device

A technology of disconnection and capsule, applied in the field of components, can solve the problems of large space occupation, unfavorable application of large-scale production lines, and unsuitable for large-scale production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

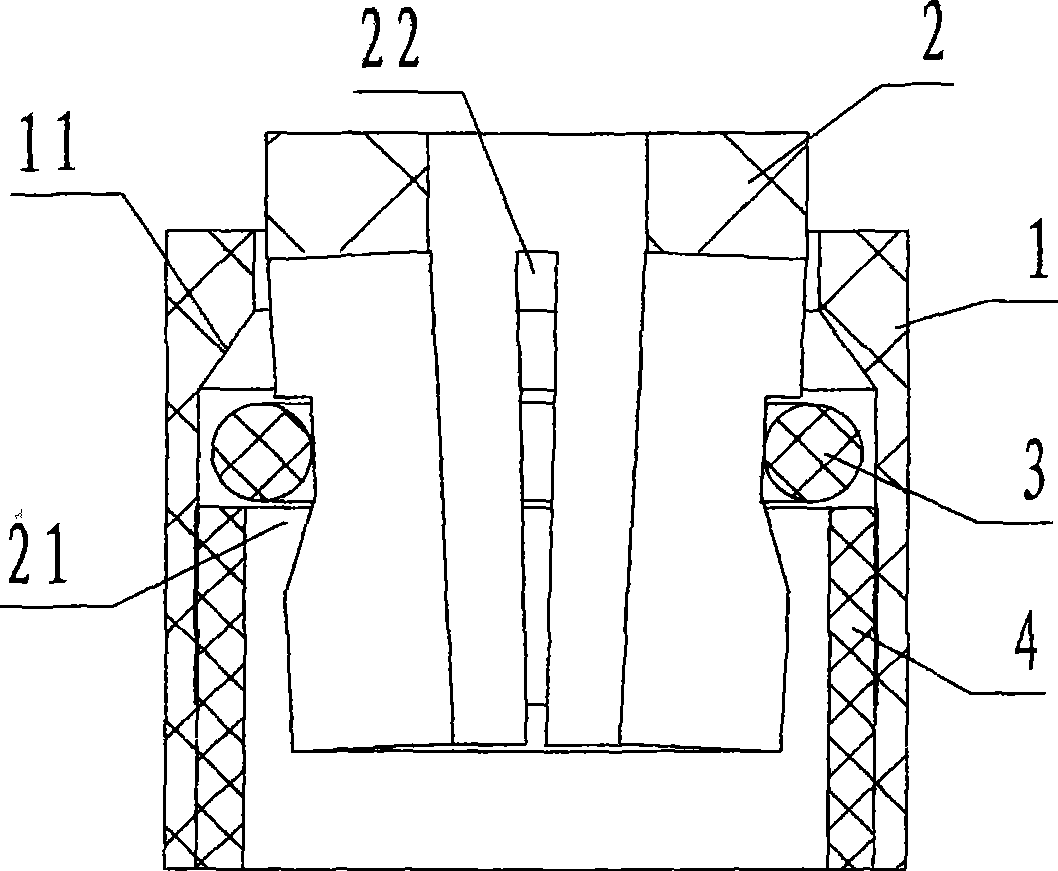

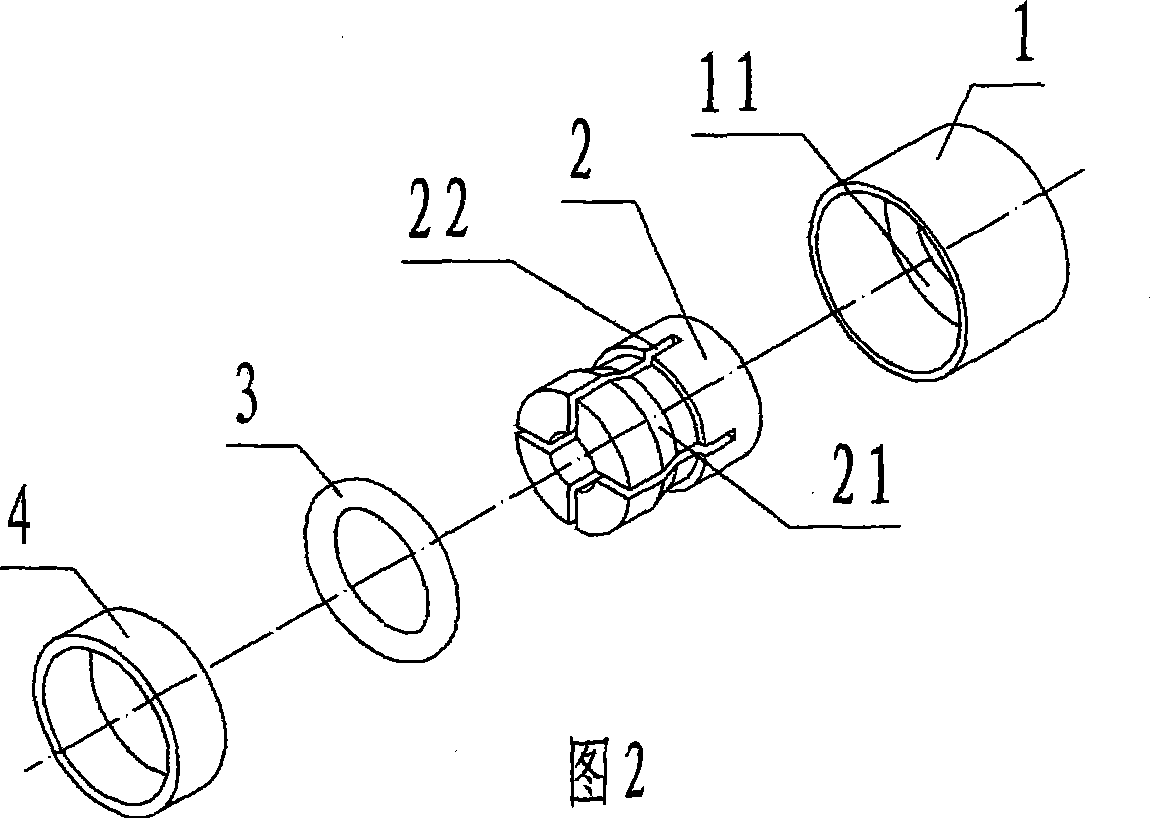

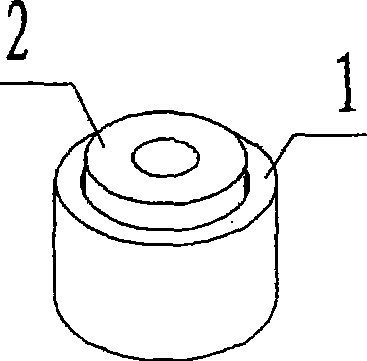

[0028] refer to figure 1 ,figure 2, image 3 , a kind of capsule pull-out conjoined device of the present invention comprises a jacket 1, a flexible chuck 2, an "O" ring 3, and a bushing 4, wherein: the jacket 1 has a large hole at one end and a small hole at the other end. Cylindrical plastic sleeve, the inner wall near the end of the small hole is provided with a transition cone 11; the flexible chuck 2 is a plastic sleeve, the center is a straight cylindrical through hole, and the outer wall of the middle part of the cylinder is provided with a cone. The face is connected with the straight annular step groove 21, from one end near the tapered surface to the 3 / 4 pipe body, there is a multi-lobe jaw formed by the conforming groove 22 of the cross opening, and the other end is a flat end; the "O The "shaped ring 3 is an annular plastic ring with a circular cross section; the bush 4 is a cylindrical plastic pipe sleeve.

[0029] Combination (mutual position and relationship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com