Small light numerically-controlled bus processing machine

A busbar processing machine, light and small technology, used in forming tools, metal processing equipment, perforation tools, etc., can solve the problems of inaccurate angle ruler scale, large volume, difficult and accurate bending angle, etc., and achieve various effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

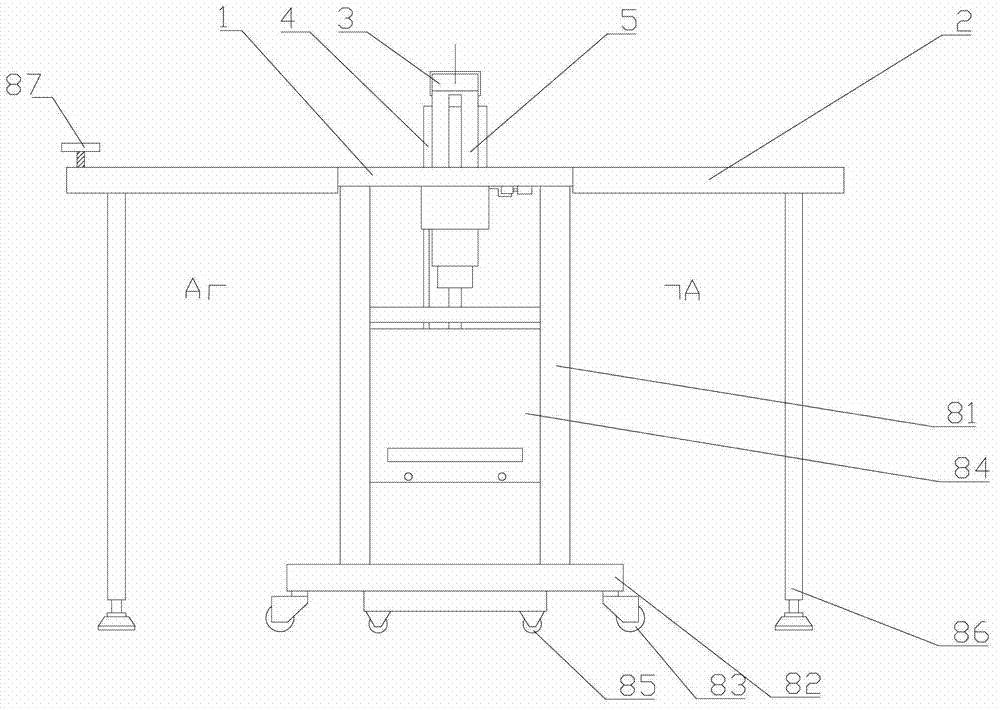

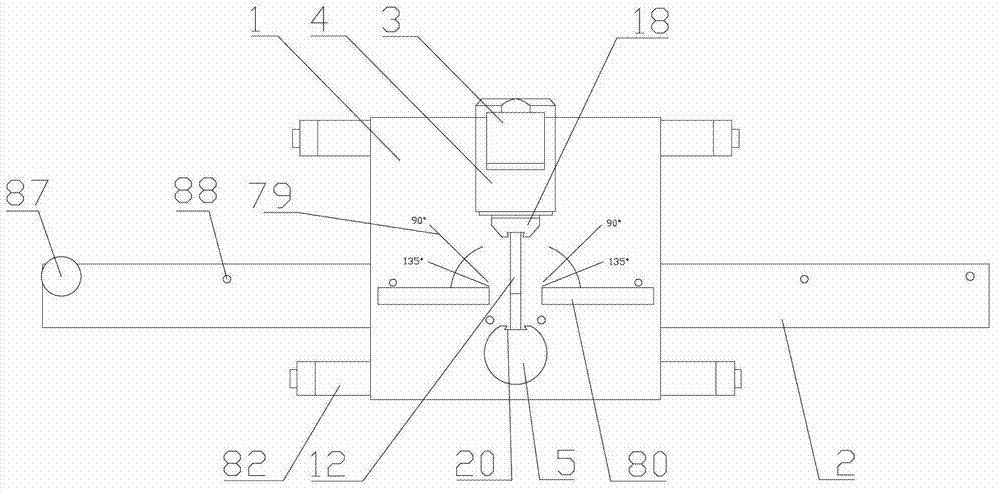

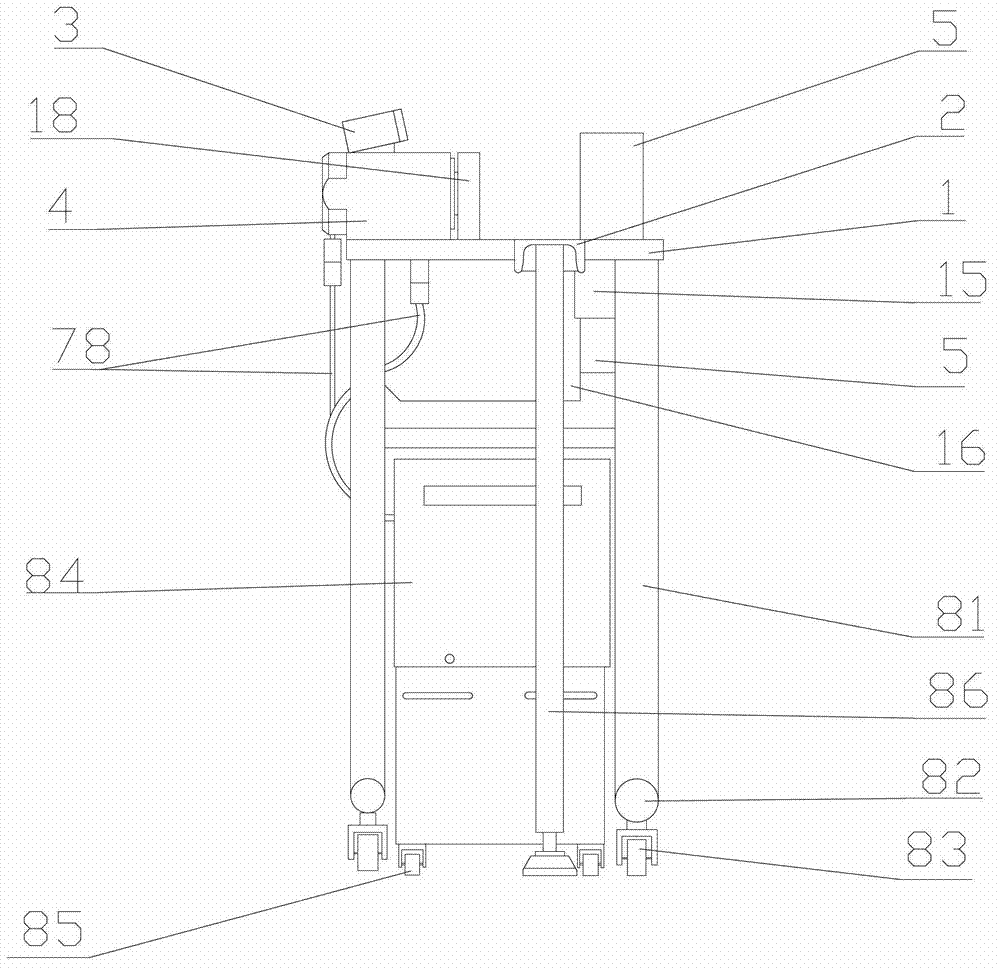

[0050] Such as Figure 1~14As shown: it includes a platen 1, a support plate 2, a grating controller 3, an oil cylinder 4 connected to a power device, a pressure head 18, a column 5, a shearing die, a punching die, a bending die, and the platen is used for loading Or connect relevant parts, be provided with vertically arranged oil cylinder socket 11, guide groove 12, column fixing hole 13 successively on the platen, described oil cylinder is inserted in the oil cylinder socket by the oil cylinder foot 14 that oil cylinder lower wall surface is provided with, The oil cylinder is fixed on the platen by bolts, and the column passes through the column fixing hole 13 and is sleeved on the reinforcing sleeve 15 provided below the column fixing hole; The reinforcing plate 16 perpendicular to the platform is connected to the direction from the end to the column, and the reinforcing plate is connected with the column and the reinforcing sleeve; the reinforcing plate plays the role of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com