A sponge mop demoulding device

A demoulding device and sponge technology, applied in the field of sponge mop demoulding device, can solve the problems of low demoulding efficiency, time-consuming and laborious, etc., and achieve the effects of improving demoulding efficiency, expanding the scope of application, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

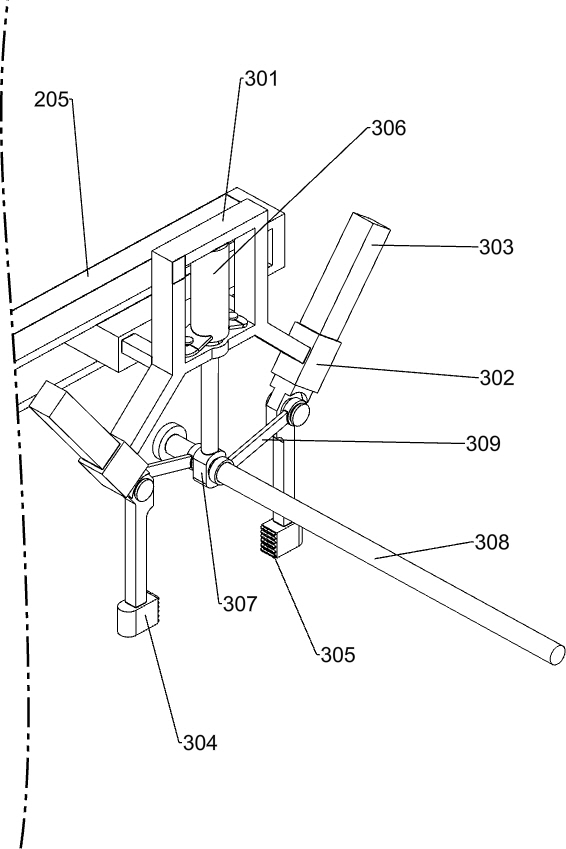

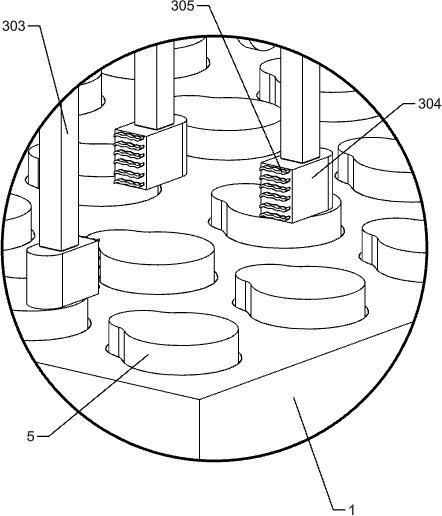

[0024] A sponge mop demoulding device, such as Figure 1-2 As shown, it includes a sponge mop mold 1, an adjustment mechanism 2 and a demoulding mechanism 3, the sponge mop mold 1 is used for the forming of the sponge mop body 5, and the sponge mop mold 1 is placed on the ground on the left and right sides. The adjustment mechanism 2, the adjustment mechanism 2. The upper part is provided with a demoulding mechanism 3, and the demoulding mechanism 3 is located above the sponge mop mold 1.

[0025] When the worker uses this equipment to demould the sponge mop body 5 in the sponge mop mold 1, first adjust the adjustment mechanism 2 to a suitable height according to the height of the sponge mop mold 1, and then start the demoulding mechanism 3 to remove the sponge mop. The main body 5 is demolded.

Embodiment 2

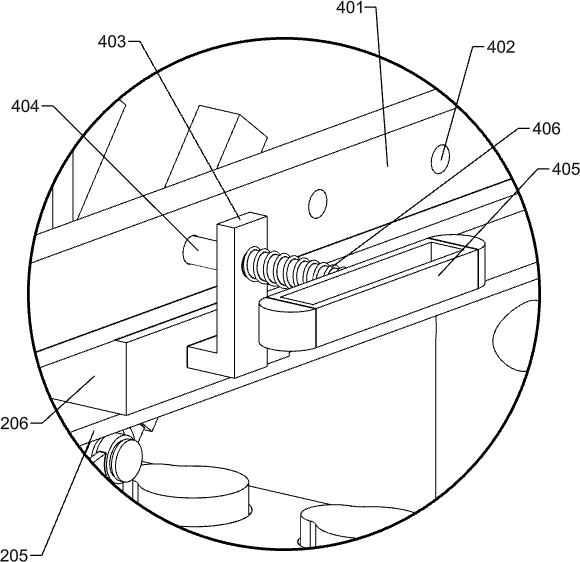

[0027] On the basis of Example 1, as Figure 3-9 As shown, the adjustment mechanism 2 includes a large adjustment plate 201, a small adjustment plate 202, a fixed rod 204, a slide rail 205, a slider 206 and a cross rod 207. Large adjustment plates are placed on the ground on the left and right sides of the sponge mop mold 1. 201, the inside of the large adjustment plate 201 is slidably provided with a small adjustment plate 202, the large adjustment plate 201 is in contact with the small adjustment plate 202, the large adjustment plate 201 and the small adjustment plate 202 are both provided with through holes 203, through holes 203 The shape is circular, the fixing rod 204 can be inserted into the through hole 203, the fixing rod 204 is matched with the through hole 203, the tops of the small adjustment plates 202 on the left and right sides are installed with horizontally arranged sliding rails 205, and the sliding rails 205 slide inside A sliding block 206 is provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com