Stackable low depth tray

A tray, depth technology for sustainable packaging, sustainable manufacturing/processing, medical formulations with inactive ingredients, etc., that can address reduced structural integrity or bottle stability, uneven tray cooling, warpage and size inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

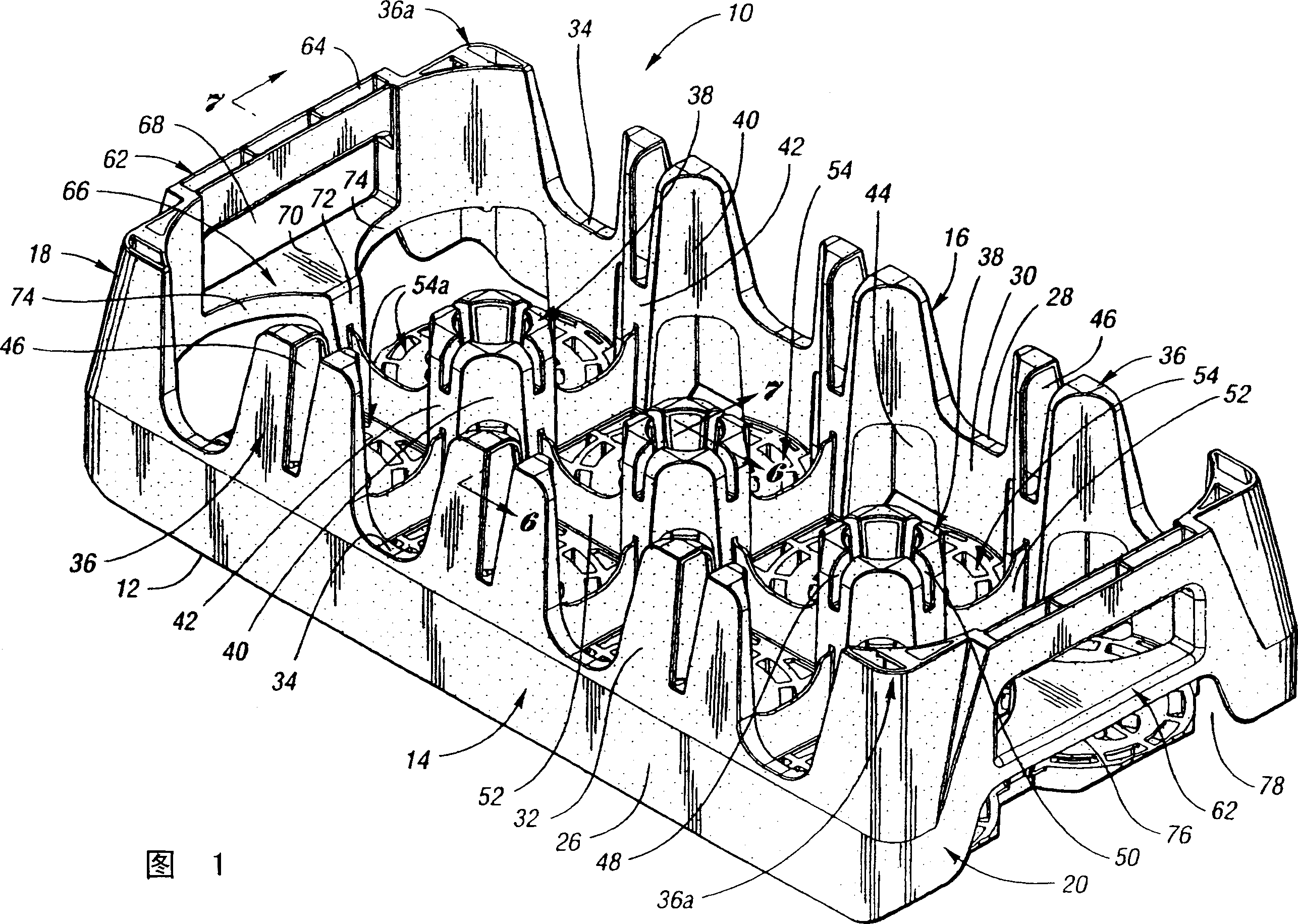

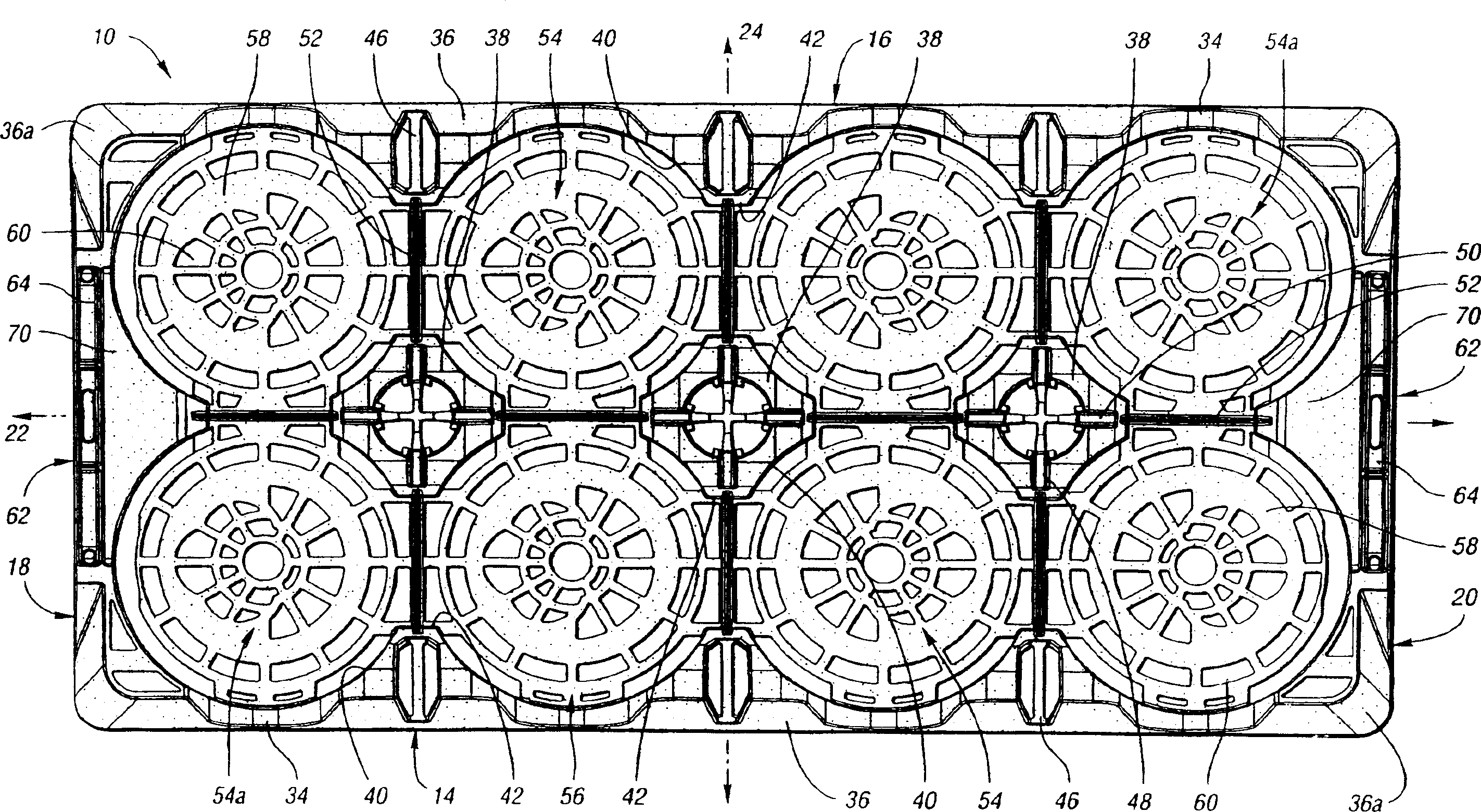

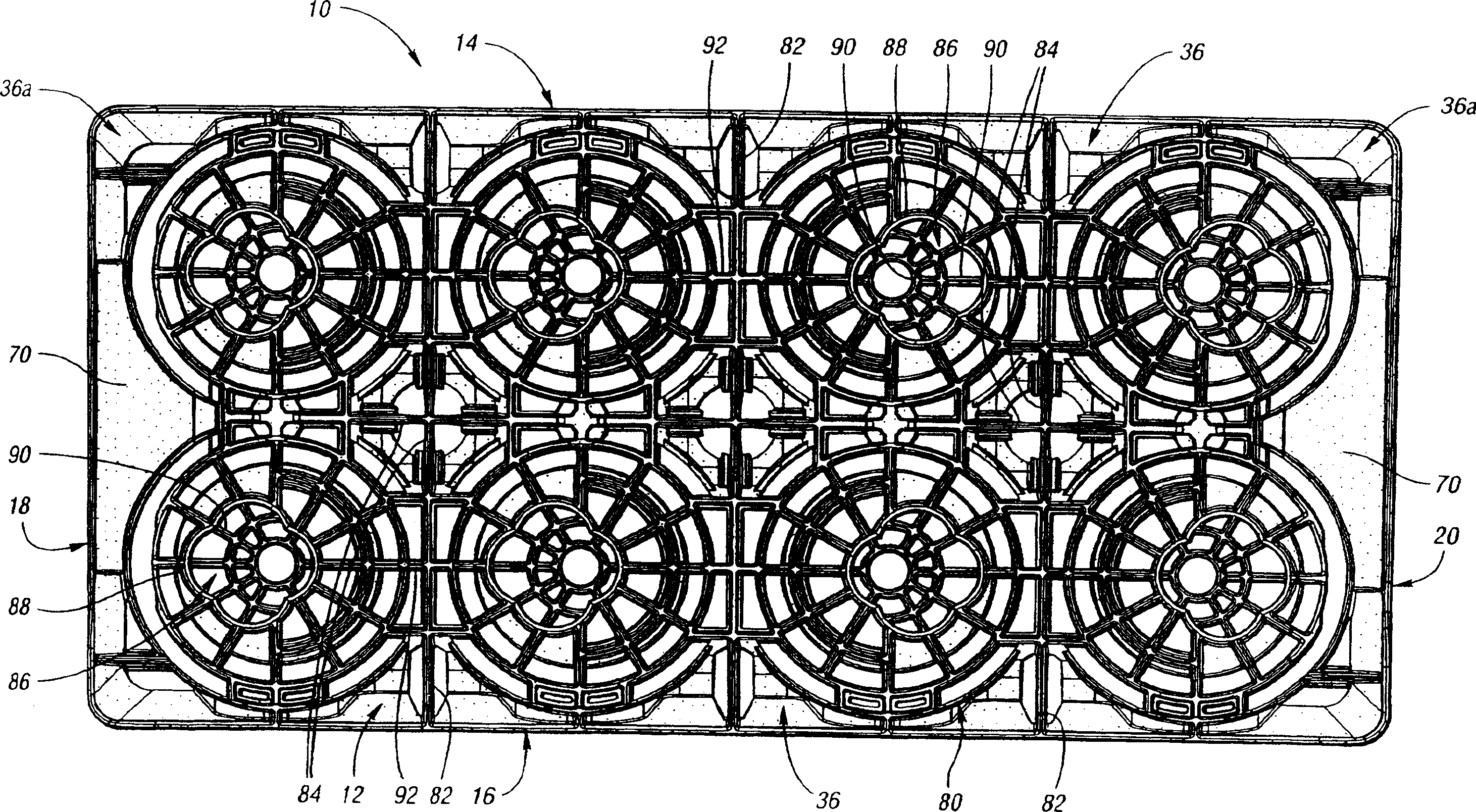

[0029] 1-5 show several views of a low depth pallet 10 according to the present invention. Although the tray 10 is suitable for a variety of purposes, the tray 10 is particularly suitable for storing and transporting bottles B (see FIG. 8 ). Tray 10 includes a bottom 12 or floor element ( Figure 2-3 best shown in ), a first pair of opposing walls 14,16 and a second pair of opposing walls 18,20. For convenience, and without additional limitation, the first pair of opposing walls 14, 16 will be referred to herein as side walls and the second pair of opposing walls 18, 20 will be referred to herein as end walls. The side walls 14, 16 and end walls 18, 20 are joined to each other to form a wall structure, joined to the base 12 and extending upwardly therefrom. Preferably, the side walls 14, 16, end walls 18, 20 and bottom 12 form an integrated unitary member of unitary construction. Tray 10 generally surrounds a longitudinal axis 22 and a transverse axis 24 thereof (see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com