A pressure vessel sensor lead wire sealing device

A sensor lead wire and sealing device technology, applied in pressure vessels, engine seals, fixed-capacity gas storage tanks, etc., can solve the problems of lead wire damage, damage to the overall originality of the sensor, and inconvenient centralized wiring, etc., to achieve a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

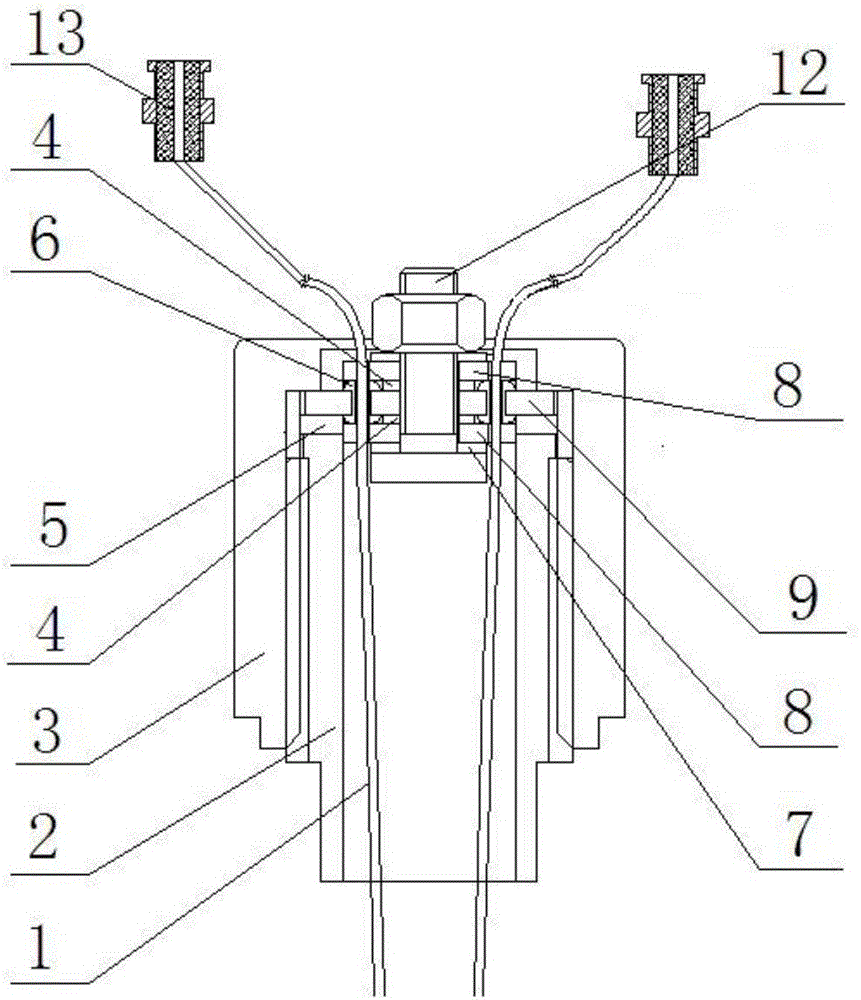

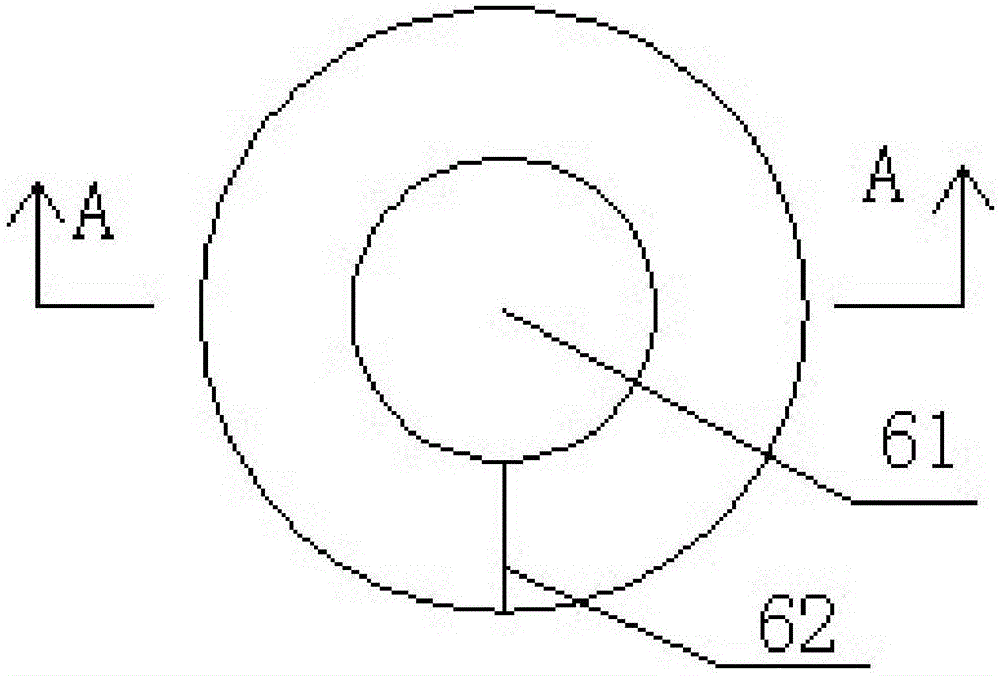

[0029] Such as figure 1 A pressure vessel sensor lead wire sealing device shown includes a lead wire tube 2 for leading the lead wire out of the container, and a sealing disc 9 pressed against the nozzle of the lead wire tube 2 by a fixing member 3. Since one end of the lead wire tube is provided with a The BNC connector has a large diameter, and the sealing disc 9 is set as two separate structures of the outer disc 91 and the inner disc 92, and the inner disc is located in the outer disc to facilitate the extraction of the BNC connector. It is convenient to fix the lead wire, set the lead wire sealing ring 6, and set a plurality of lead wire holes 93 between the outer disk 91 and the inner disk 92, put the lead wire sealing ring 6 in the lead wire hole 93, ensure the stability of the lead wire sealing ring 6, and Ensure the stability of the leads. The lead wire sealing ring 6 uses the lead wire fixing hole 61 to fix the lead wire. In order to facilitate the introduction or c...

Embodiment 2

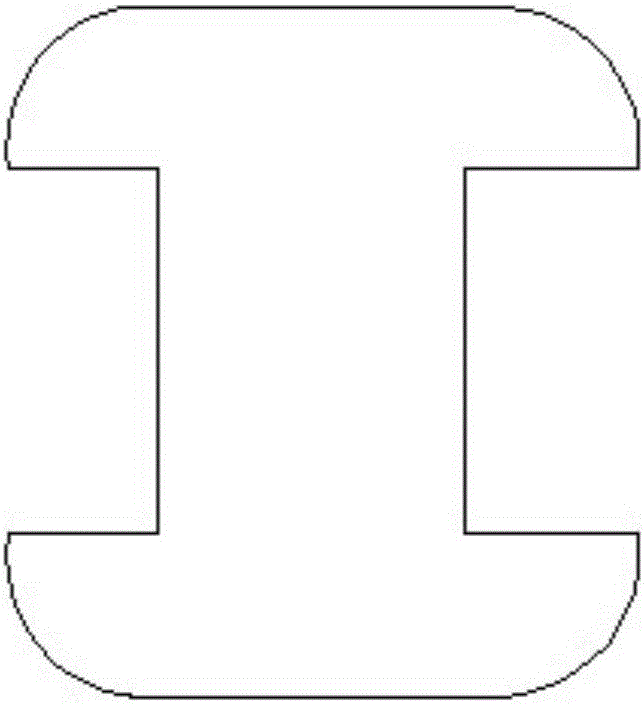

[0032] refer to figure 1 , figure 2 with image 3 In the shown pressure vessel sensor lead wire sealing device, in order to further enhance the stability of the lead wire sealing ring structure and enhance the leak-proof performance of the lead wire hole, this embodiment is optimized on the basis of the above-mentioned embodiments. The lead wire seal The section of circle 6 becomes " I " font. The lead hole 93 between the outer disc 91 and the inner disc 92 fixes the lead wire sealing ring 6 from the horizontal plane of the sealing disc; 92 is stuck, that is, the two ends of the lead wire sealing ring 6 further fix the lead wire sealing ring 6 from the vertical surface of the sealing disc to ensure the stability of its structure. Its specifications at both ends of the lead wire sealing ring 6 are greater than the lead wire hole 93, which can improve the reliability of sealing the lead wire hole 93 and improve the leak-proof capability.

[0033] In actual operation, the th...

Embodiment 3

[0035] refer to figure 1 In the shown pressure vessel sensor lead wire sealing device, in order to further enhance the leak-proof ability and pressure-bearing ability, this embodiment is optimized on the basis of the above-mentioned embodiment, and the upper and lower surfaces of the sealing plate 9 are respectively Overlap the first pressure plate sealing gasket and the second pressure plate sealing gasket to enhance the sealing ability of the gap holes connected between the lead holes, and the more the number of pressure plate sealing gaskets, the greater the pressure bearing capacity. stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com