Device for electrohydraulic forming of sheet metal

a technology of electrohydraulic forming and sheet metal, which is applied in the field of electrohydraulic forming devices of sheet metal, can solve the problems of limited number of spark gaps that can be switched in series, and achieve the effect of increasing the productivity of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

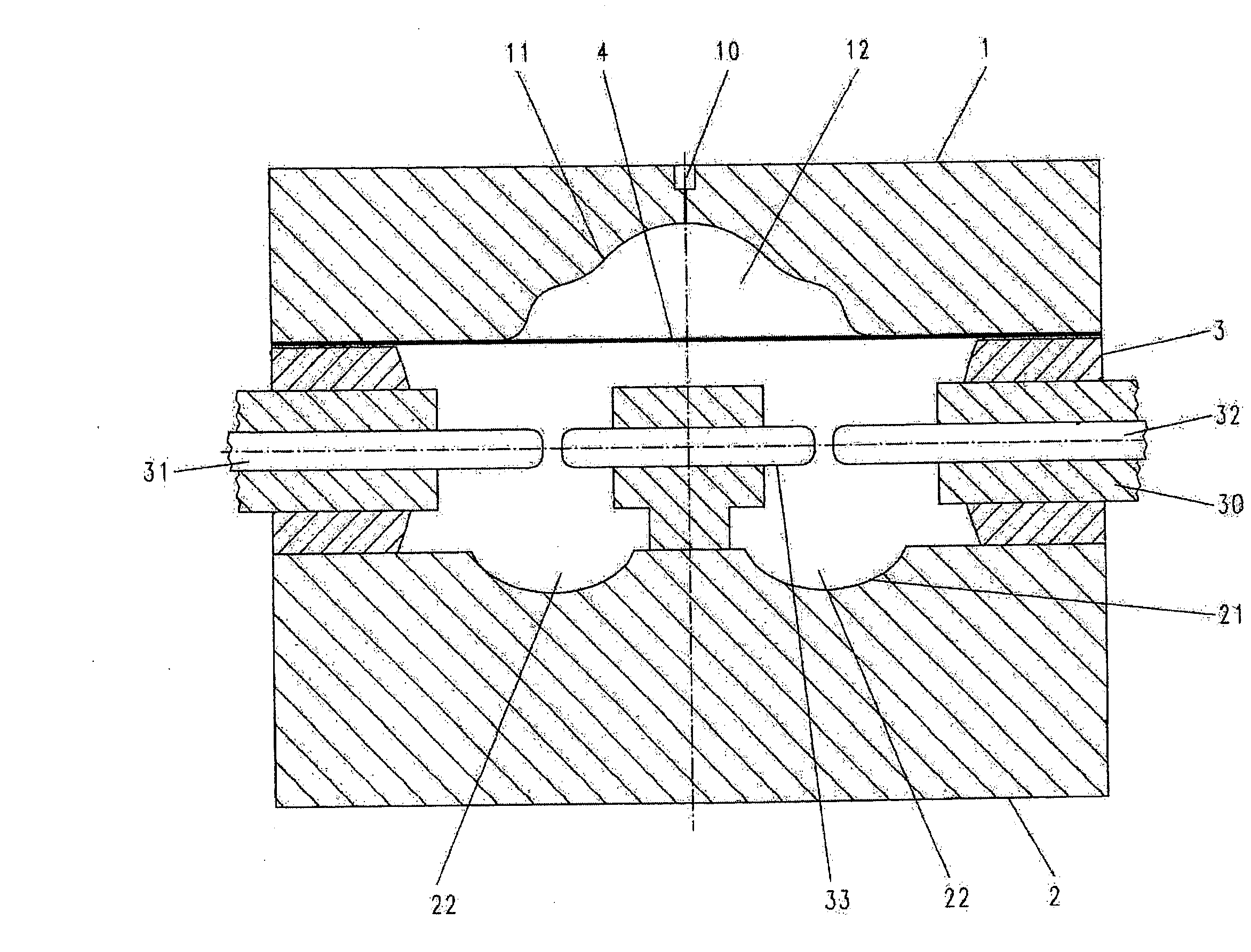

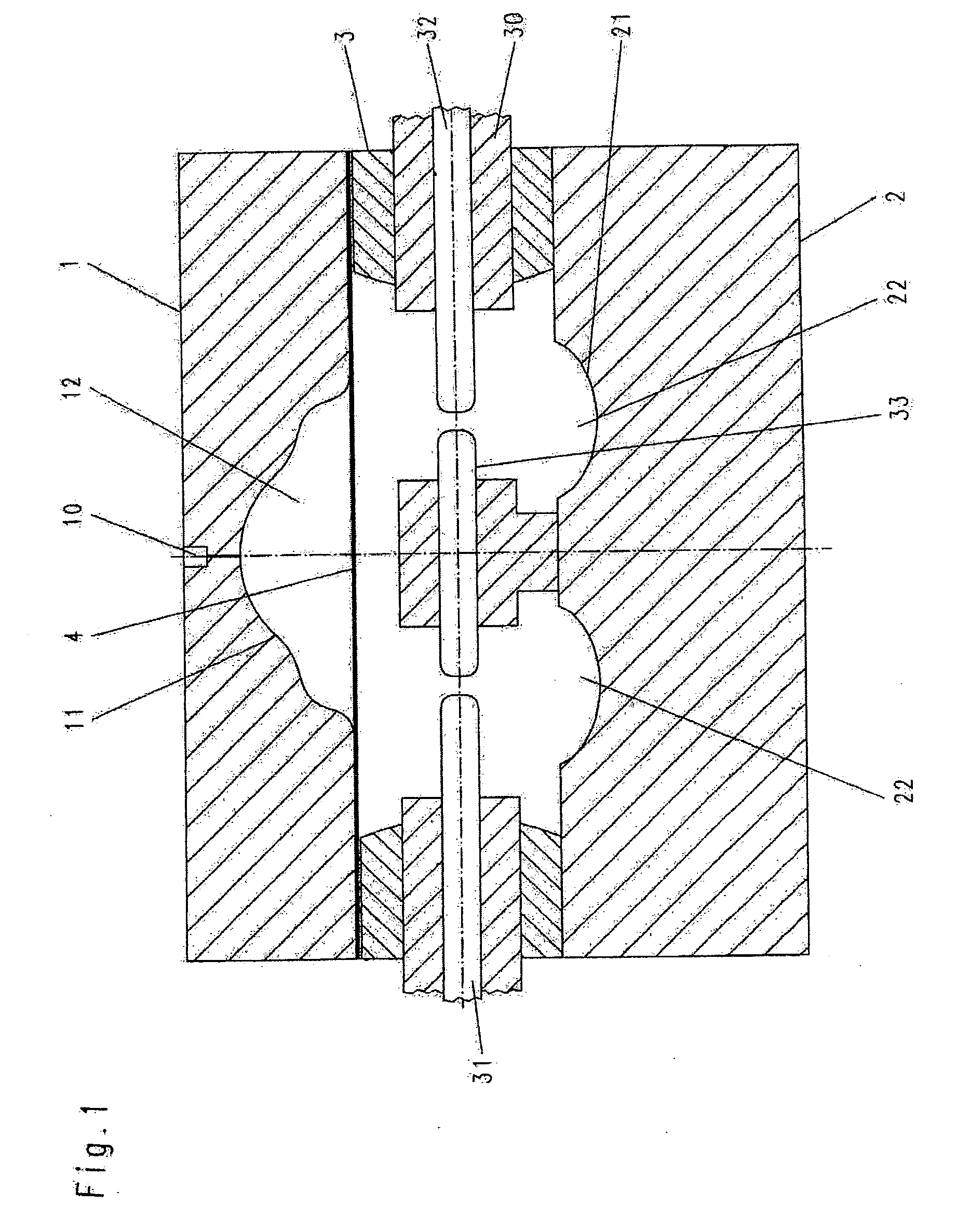

[0026]Turning now in detail to the drawings, FIG. 1 shows an exemplary embodiment of a device for electrohydraulic forming of sheet metal essentially made up of an upper die part 1 and a lower die part 2, between which an electrode frame 3 is disposed. A metal sheet 4 can be clamped in place between electrode frame 3 and upper die part 1, in fluid-tight manner.

[0027]A die plate 11 is placed into upper die part 1, which plate has the contour to be shaped into metal sheet 4. Furthermore, a line 10 for evacuating the chamber formed by metal sheet 4 laid in and die plate 11 is provided in upper die part 1.

[0028]Lower die part 2 has reflectors 21 configured essentially parabolically or elliptically, which are disposed to lie opposite die plate 11 of upper die part 1. Reflectors 21 serve to reflect discharge energy that impacts them, in the direction of die plate 11.

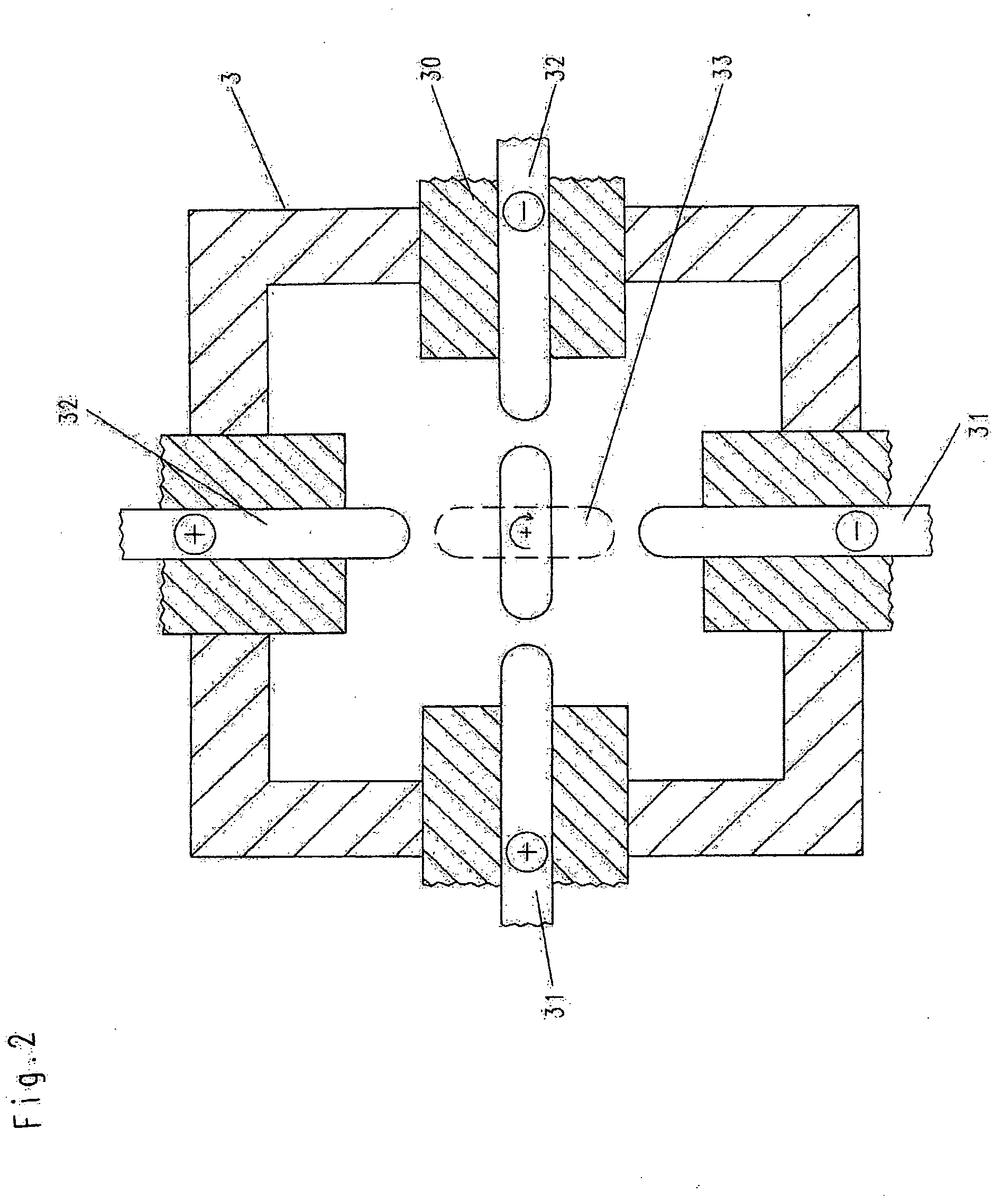

[0029]An electrode frame 3 is disposed on lower die part 2. In the exemplary embodiment according to FIG. 2, electrode frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com