Device for preparing carbon fiber thermoplastic dipping strips by water base powder dipping and method thereof

A powder impregnation and impregnation device technology, which is applied to belts, other household utensils, household utensils, etc., to reduce the risk of fire and explosion, prevent settlement, and improve roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] Example 1

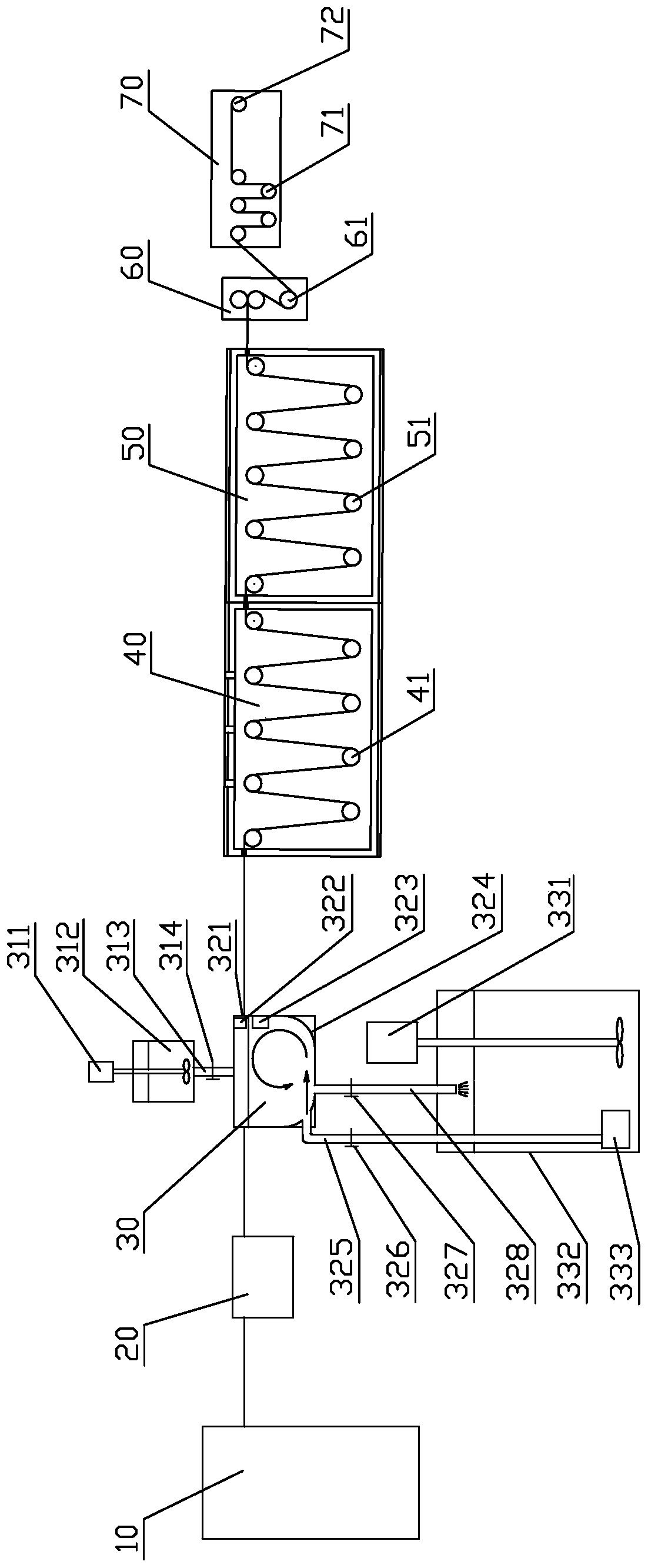

[0053] Such as Figure 1-2 Shown:

[0054] The device for preparing carbon fiber thermoplastic impregnated tape by water-based powder impregnation includes a wire pay-off device 10, a carbon fiber surface treatment device 20, and the carbon fiber surface treatment device 20 is sequentially connected to a water-based powder suspension impregnation device 30 and a contact drying device. Drying device 40, melt dipping molding device 50, calendering device 60 and traction device 70; wherein: the water-based powder suspension dipping device 30 includes a slurry dipping device and a liquid storage device;

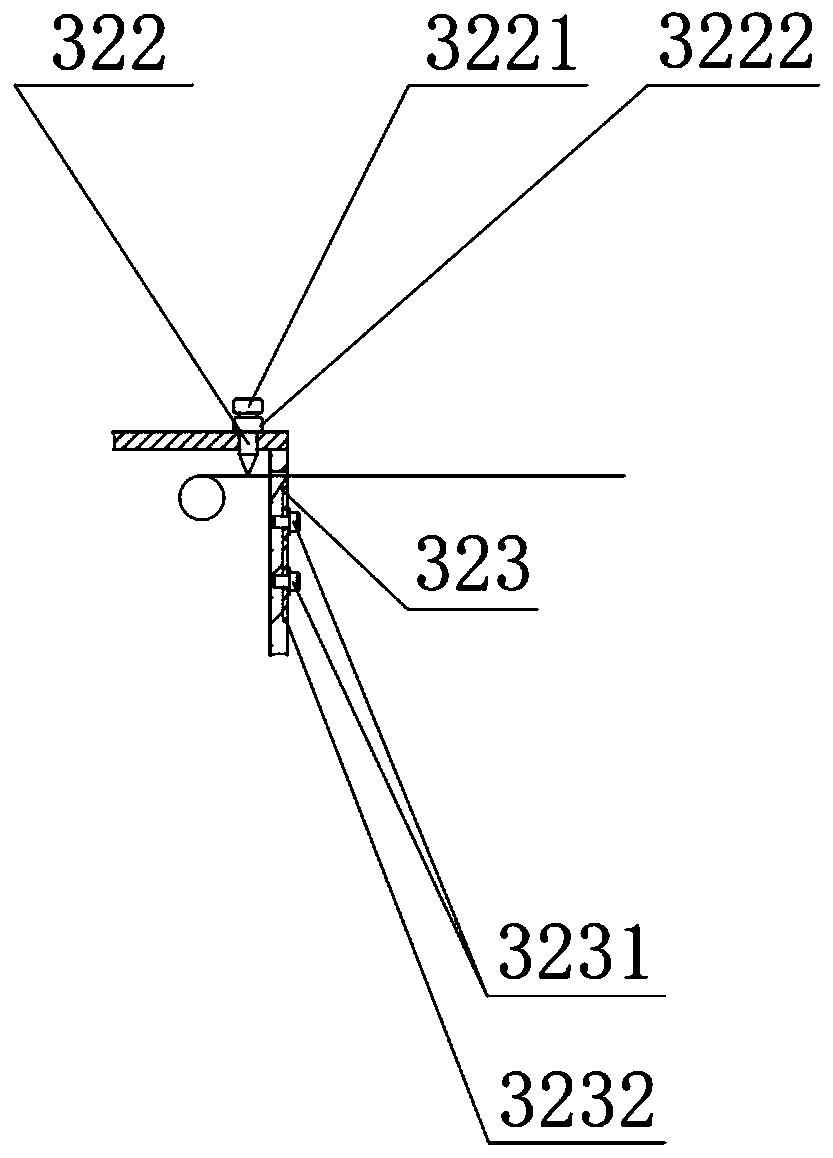

[0055] The dipping device includes a dipping tank 321 whose bottom corner 324 is a circular arc transition. One side of the dipping tank 321 is provided with an inlet pipe 325, and an inlet valve 326 is provided on the inlet pipe 325; the bottom of the dipping tank 321 is provided with a drain Pipe 328, the drain pipe 328 is provided with a drain valve 327; the drai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com