Patents

Literature

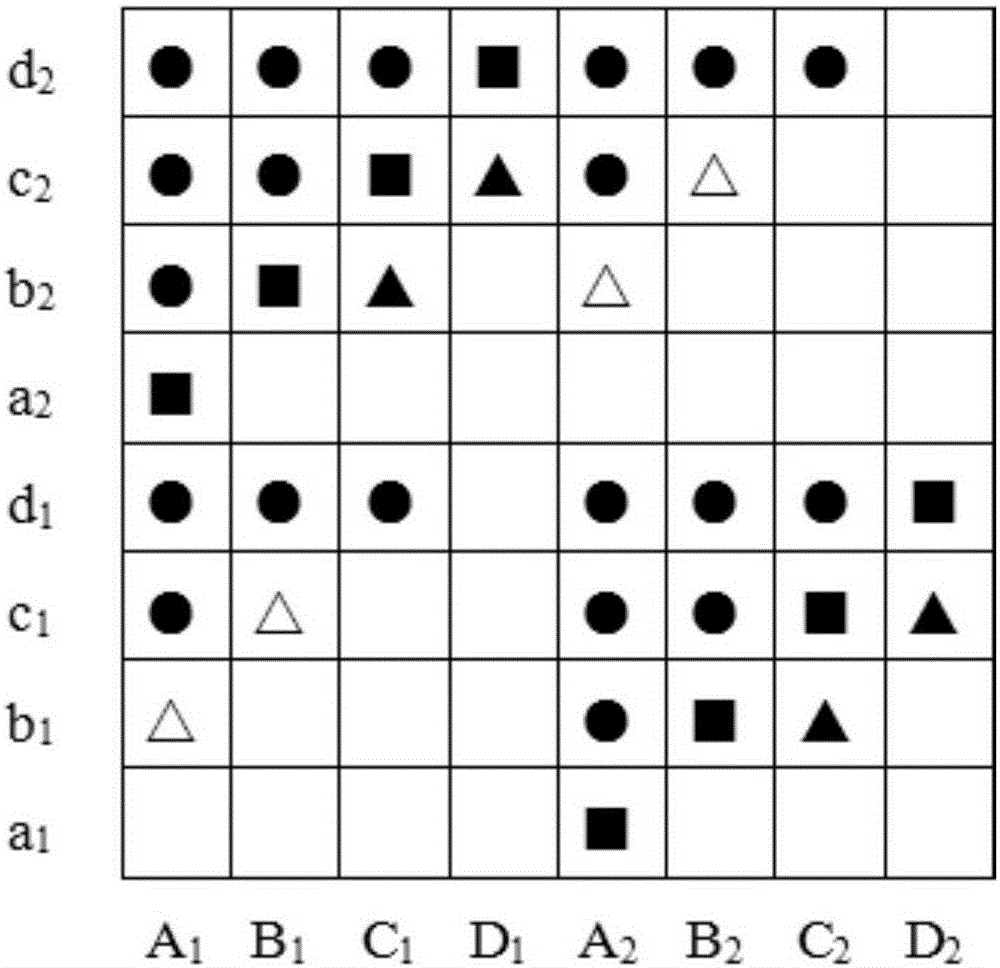

55results about How to "Good anti-stab performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

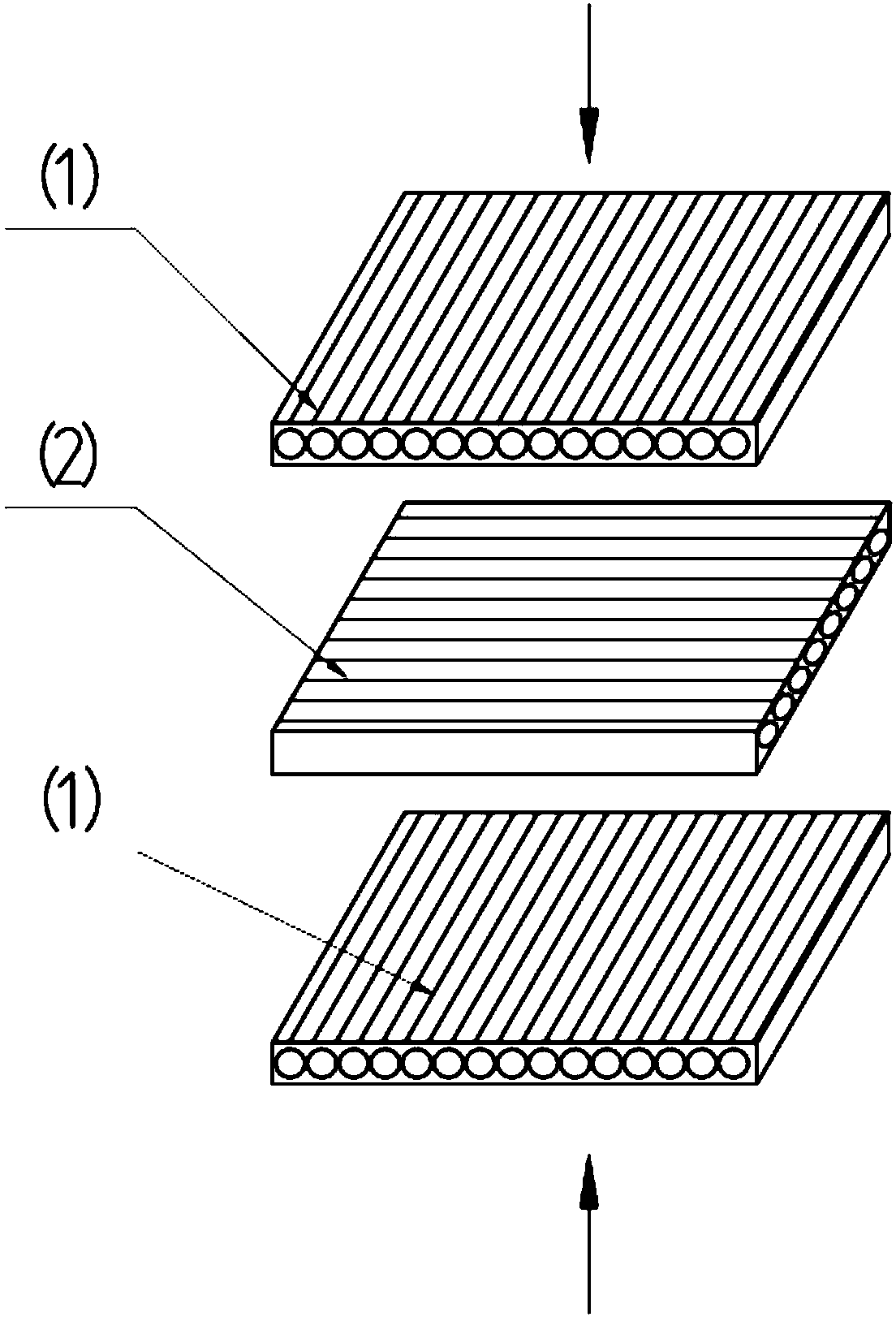

Thorn-proof composite material and preparation method thereof

ActiveCN101936684AGood anti-stab performanceWear lightSynthetic resin layered productsPersonal protection gearCushioningResin matrix

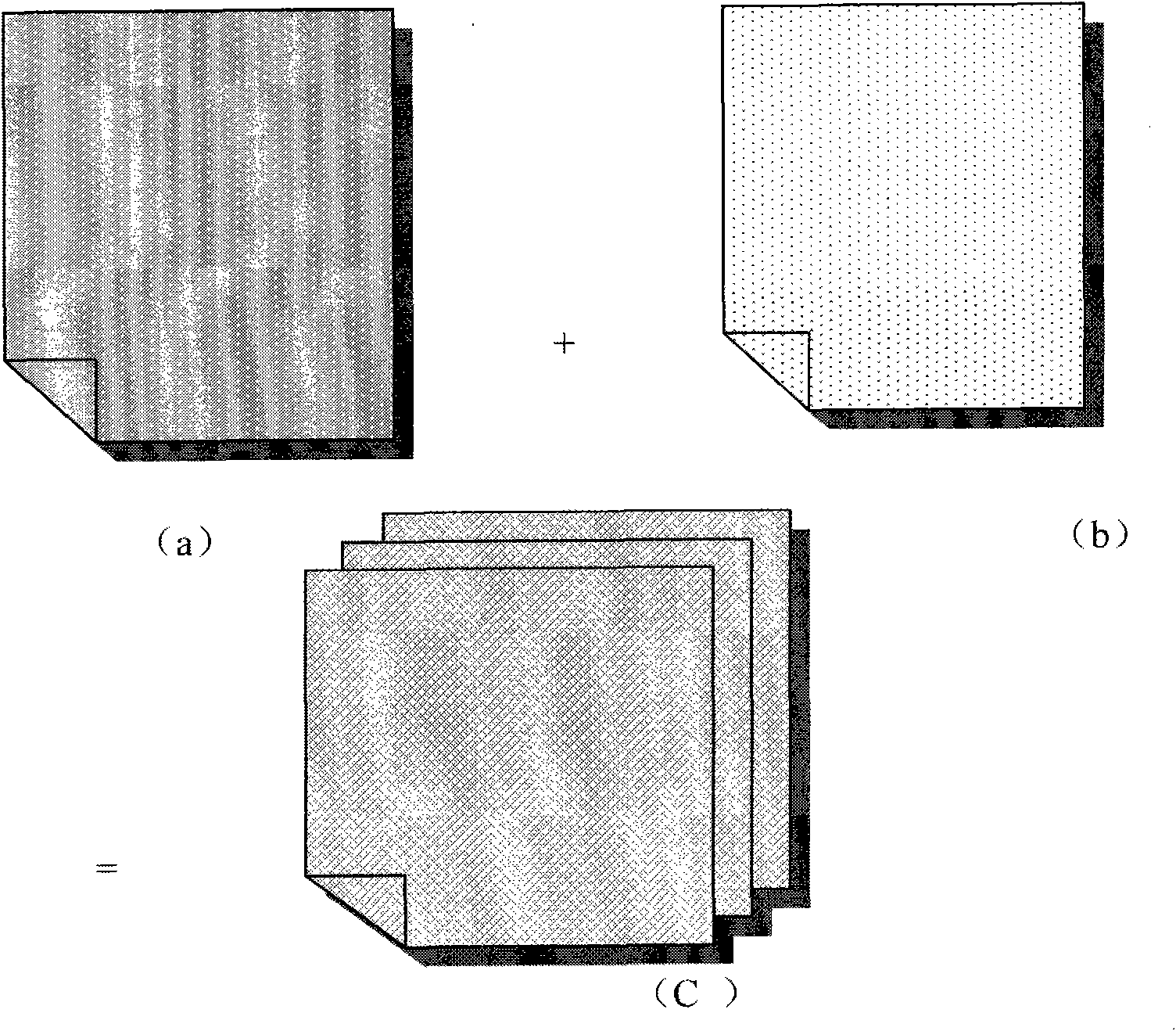

The invention provides a thorn-proof composite material and a preparation method thereof. The thorn-proof composite material comprises a plurality of single-layer composite materials with micro holes, wherein each single-layer composite material comprises a reinforcing body formed by high-performance fibers, and a resin matrix which is compounded on the reinforcing body. The thorn-proof compositematerial further comprises a cushioning material for manufacturing a soft comfortable thorn-proof composite material.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

Preparation method of soft and durable anti-penetrating material

ActiveCN107815870AIncreased durabilityGood flexibilityUltrasonic/sonic fibre treatmentGrip property fibresFiberEngineering

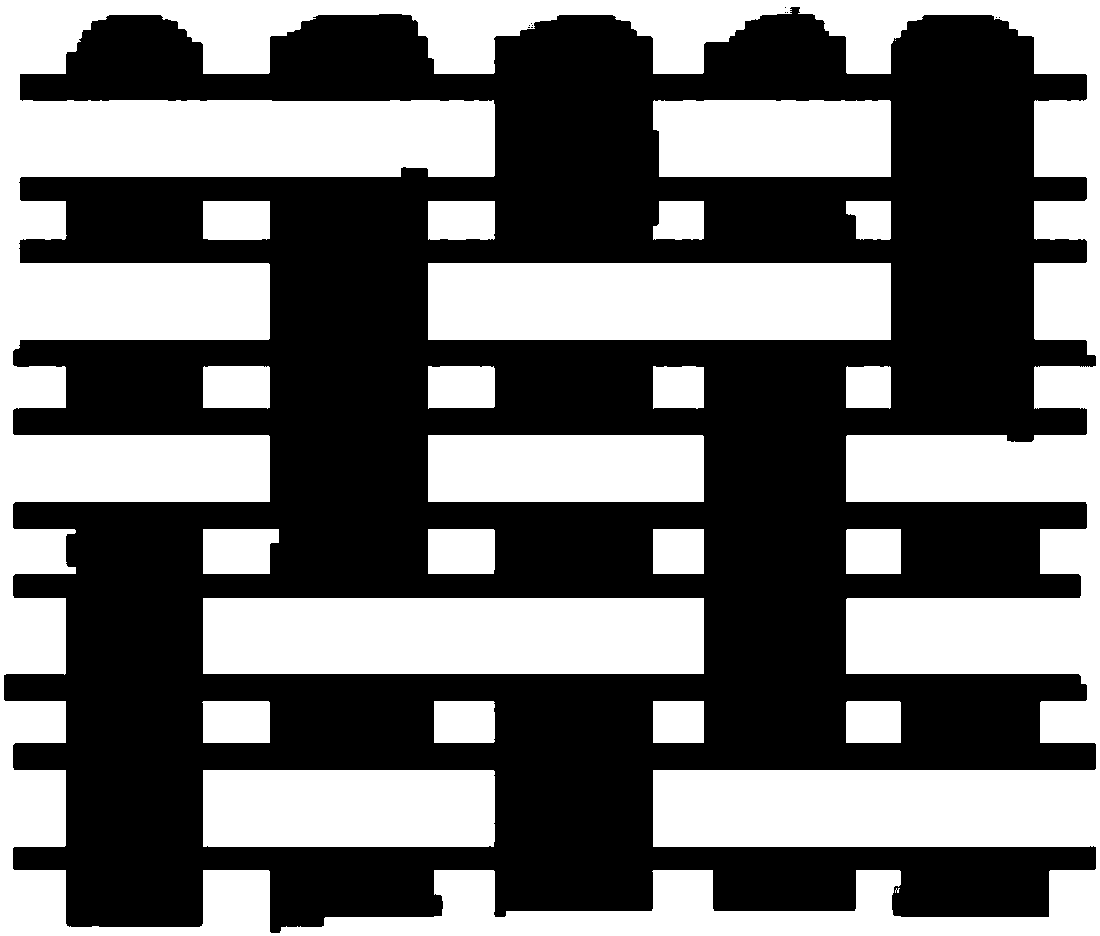

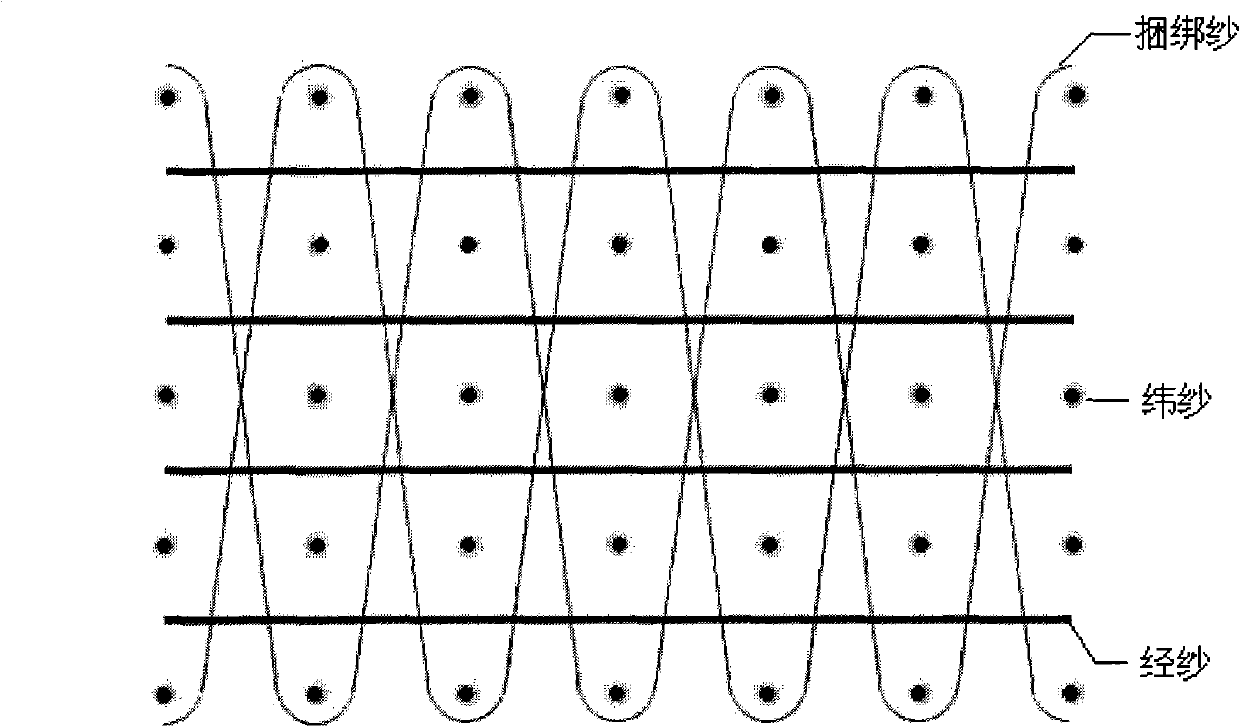

The invention discloses a preparation method of a soft and durable anti-penetrating material. The preparation method is characterized by comprising the following steps: (1) preparing shearing thickening liquid; (2) preparing a high performance fiber fabric with a special tissue structure, namely preparing a fabric from high performance fibers by virtue of a special tissue structure weaving process, putting the fabric into a vacuum drying oven, and drying at 120-150 DEG C for 2-3 hours; and (3) preparing the anti-penetrating material. According to the method, by virtue of reasonable tissue structure configuration on the fabric and plasma treatment on the shearing thickening liquid and the fabric, the shearing thickening liquid and the fabric are adequately compounded, so that the durabilityand flexibility of the anti-penetrating material are improved, and the soft and durable anti-penetrating material suitable for multiple environments of daily protective clothes of military police, armored military equipment, civil and industrial protection and the like is prepared.

Owner:江苏威之盾安防科技有限公司

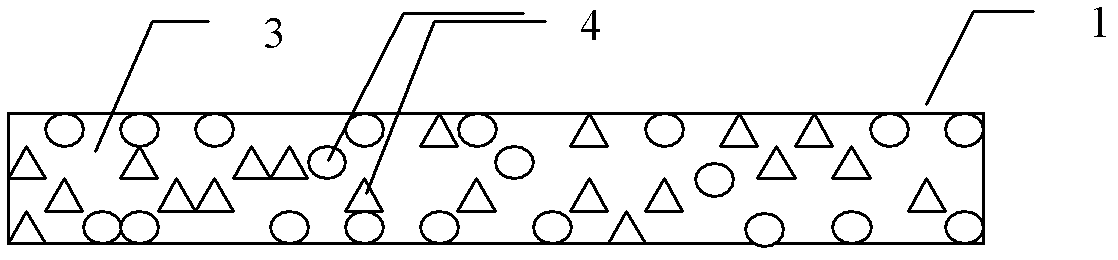

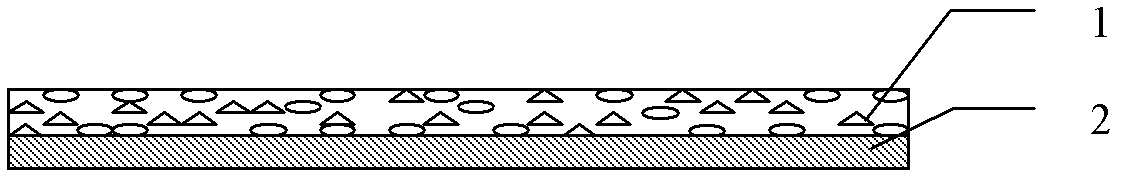

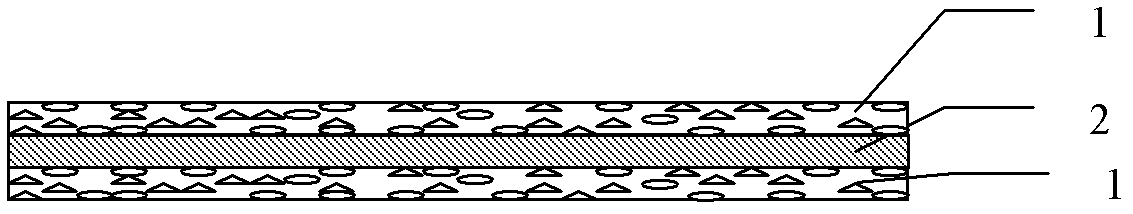

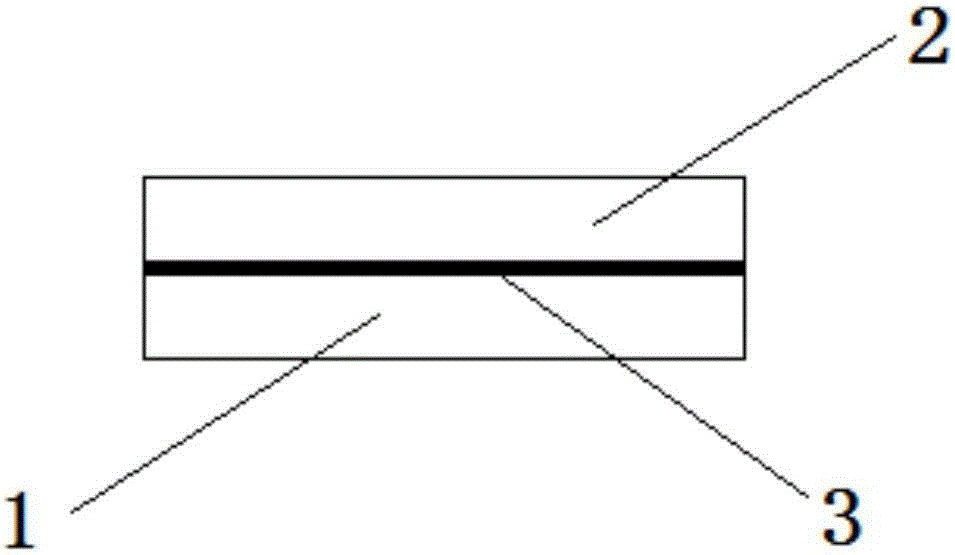

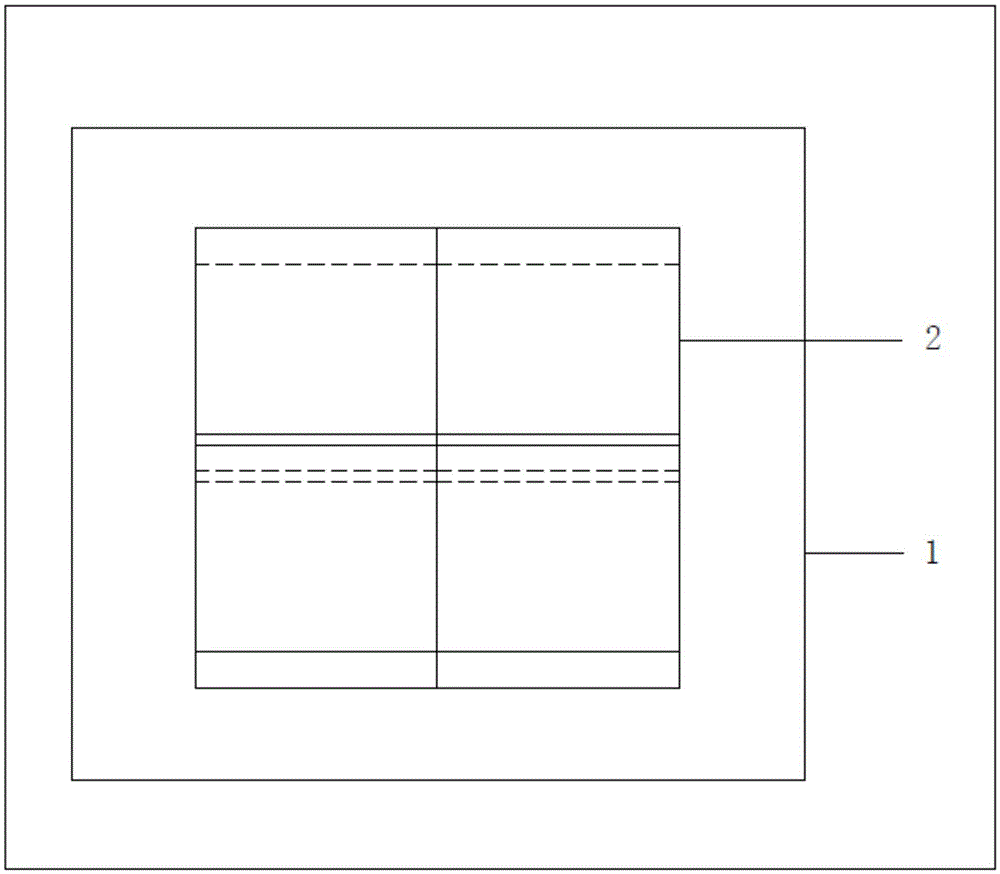

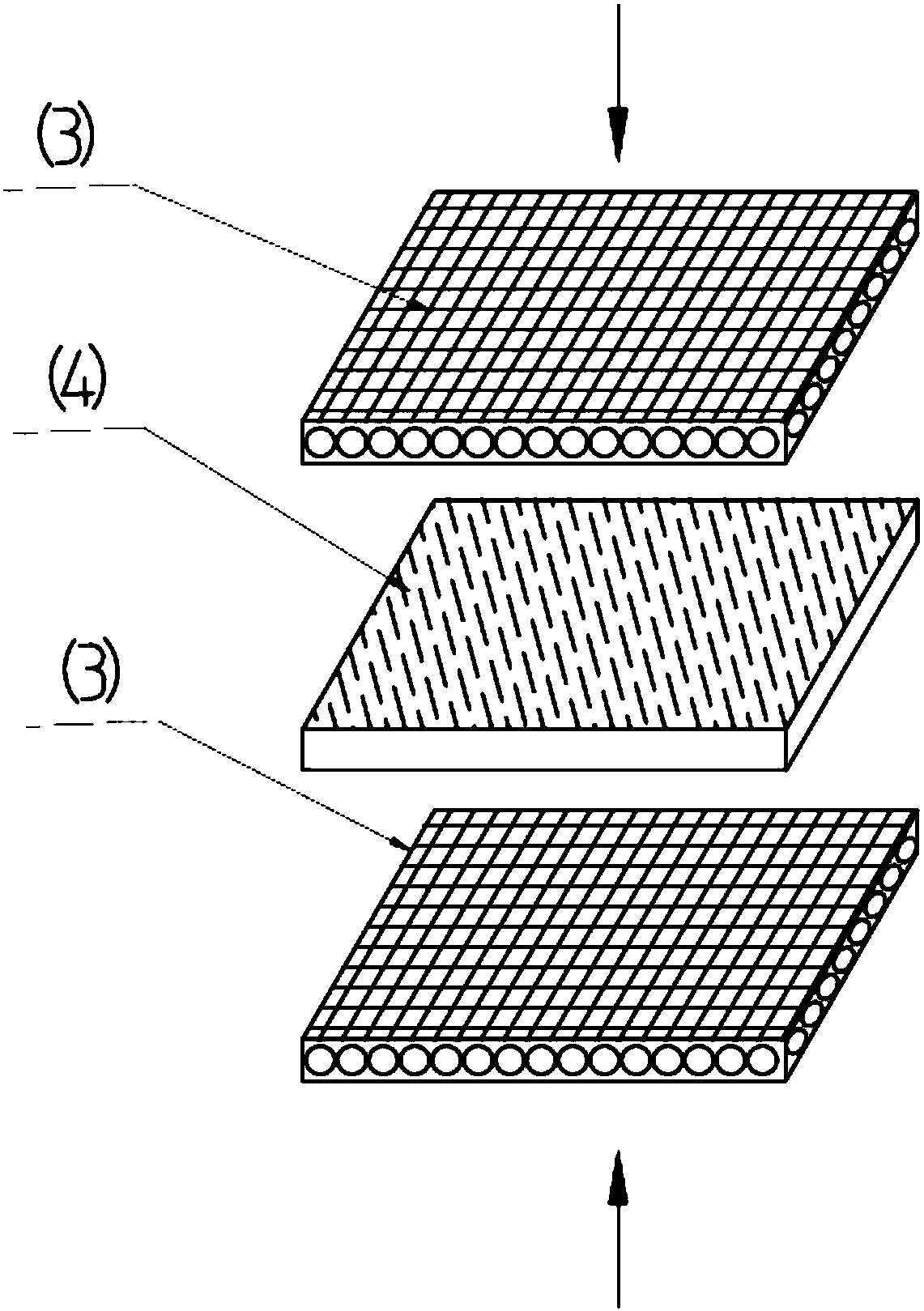

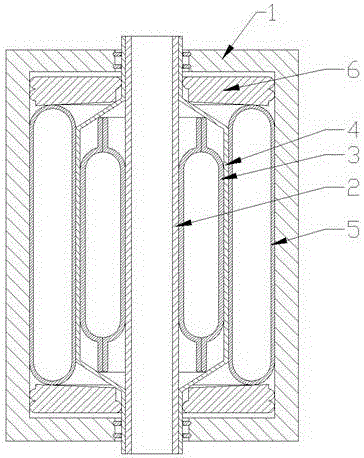

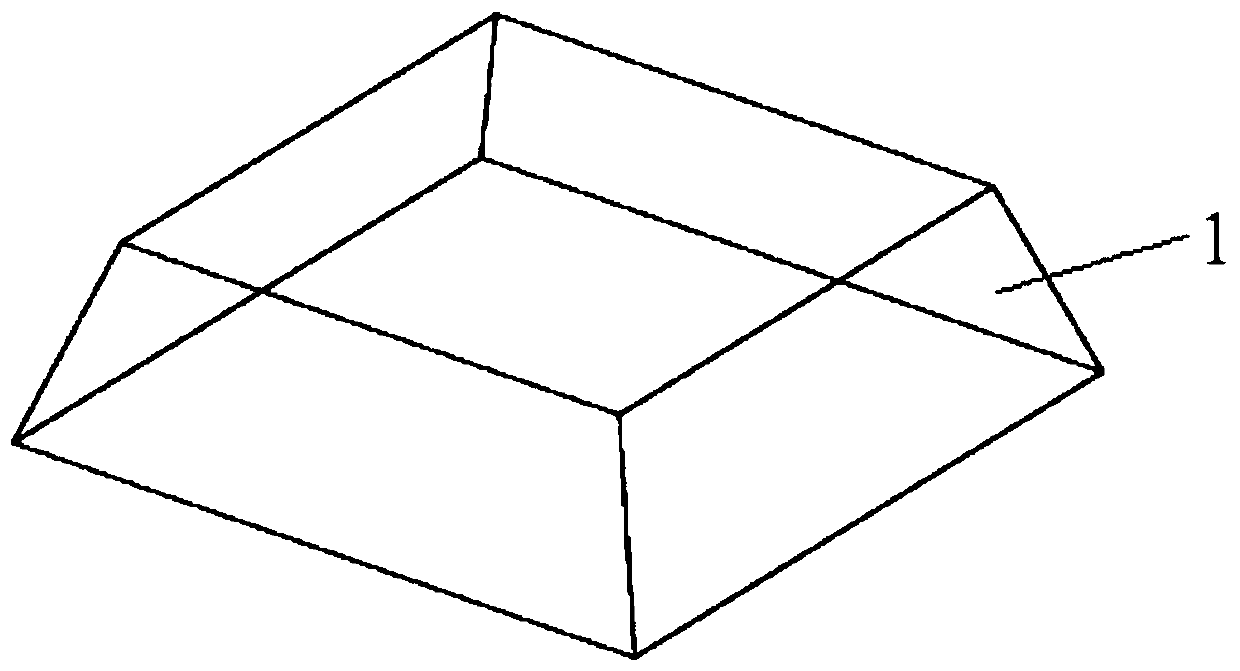

Composite puncture-proof sheet and bulletproof puncture-proof composite material

InactiveCN102493202AGood anti-stab performanceGood effectPersonal protection gearVegetal fibresMetallurgyMaterials science

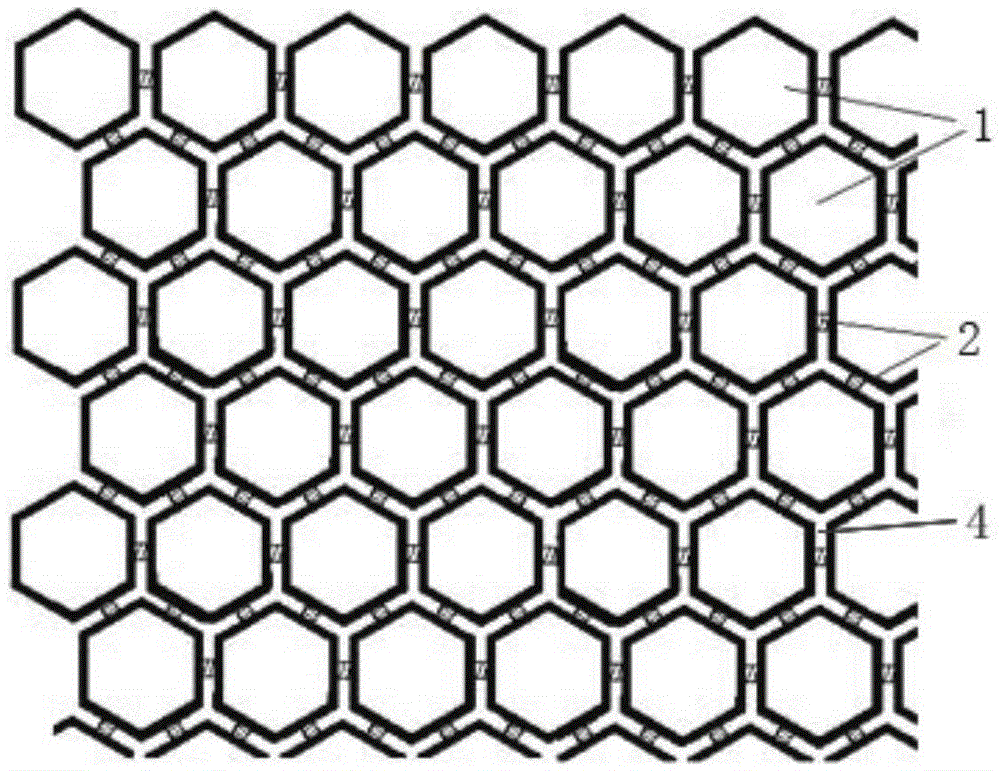

The invention belongs to the technical field of composite materials, which relates to a composite puncture-proof sheet comprising fabric 2 and a composite coating 1 which is coated on the surface of the fabric 2 and composed of a bonding matrix material 3 and a microbead material 4 dispersing in the bonding matrix material 3, wherein the parts by mass of the microbead material 4 in the coating is in a range between 10% and 70%, and the microbead material 4 is light in weight and strong in designability and can effectively improve protection ability under equal weight conditions. The composite puncture-proof sheet has good puncture-proof ability and a bulletproof function, and effects are better when a plurality of layers are used. Compared with the traditional material, under same level of protection, the composite puncture-proof sheet can substantially lighten equipment weight, reduces thickness and lowers cost. The composite puncture-proof sheet and the bulletproof puncture-proof composite material are applicable to protective inner containers of flak suits, puncture-proof suits or flak-and-puncture-proof suits for personnel protection of privates, policemen, various security personnel and special groups, and can also be used for manufacturing and processing protection tools such as anti-explosion blankets and anti-explosion tents.

Owner:山东三达科技发展有限公司

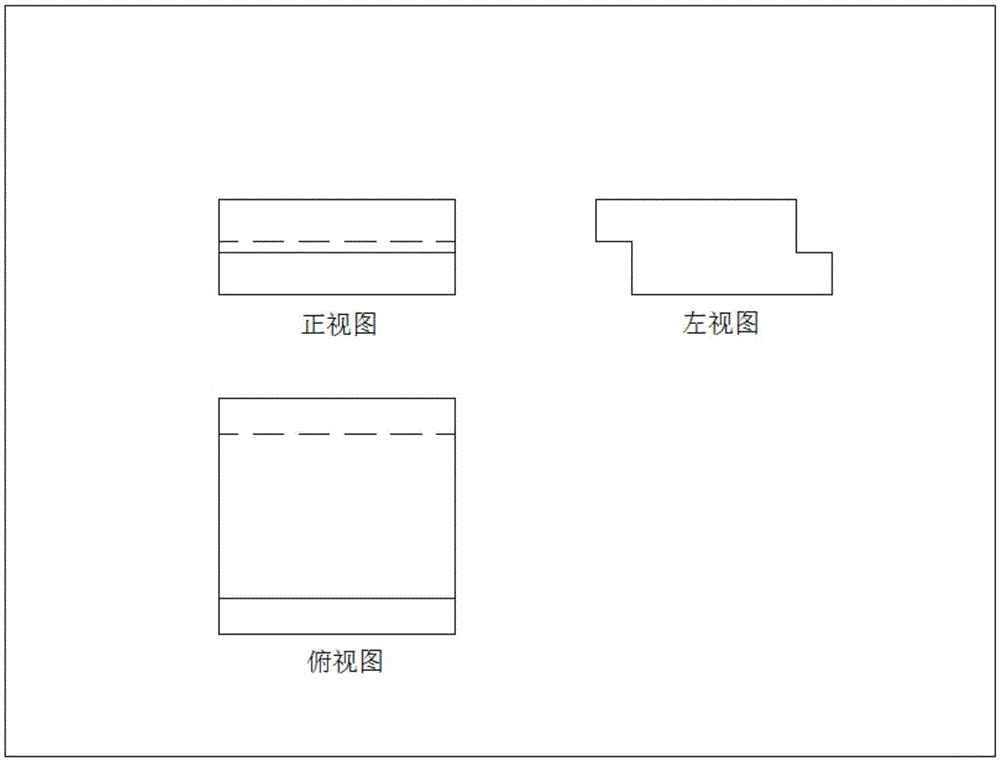

Resin-formed flexible puncture-proof fabric and preparation method thereof

The invention relates to a resin-formed flexible puncture-proof fabric and a preparation method of the resin-formed flexible puncture-proof fabric. The fabric consists of garment fabric and thermosetting resin condensates, wherein a gap exists between the thermosetting resin condensates. The preparation method comprises the following steps of: uniformly dispersing the thermosetting resin in each mesh of a screen plate so that each mesh is filled with resin; scraping residual resin on the surface of the screen plate; spreading the garment fabric on the screen plate filled with resin; applying pressure to the garment fabric, and drying; solidifying the thermosetting resin condensate on the surface of the garment fabric; and finally removing the thermosetting resin condensate from the screen plate to obtain the resin-formed flexible puncture-proof fabric. According to the invention, the thermosetting resin is a good binder before solidification, has a good binding effect with the garment fabric and relatively high strength and hardness after solidification, and can resist the puncture of a conventional tool needle tube; and the shortcomings and defects of the prior art are overcome, and the needs of the military field and civil field are met.

Owner:DONGHUA UNIV +1

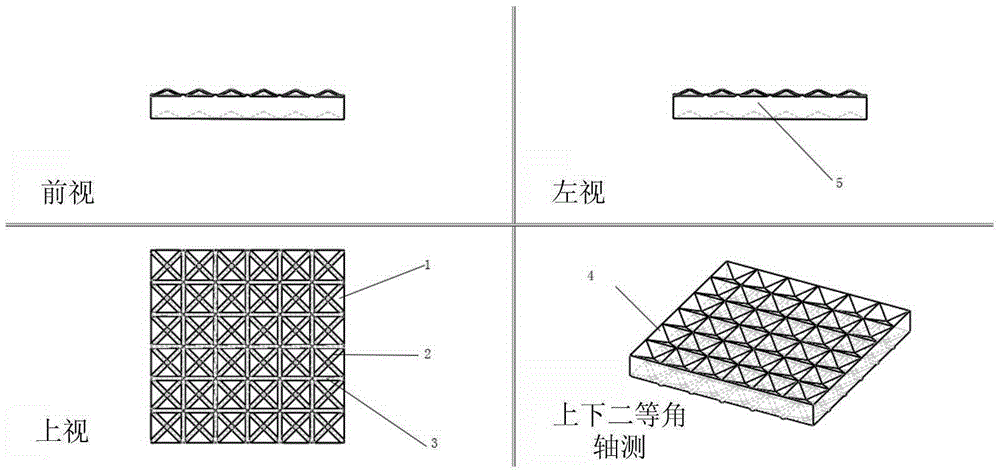

Scale armor type anti-prick chip and anti-prick device made of scale armor type anti-prick chip

ActiveCN105403106AIncrease flexibilityImprove breathabilityPersonal protection gearBionicsEngineering

The invention discloses a scale armor type anti-prick chip and an anti-prick device made of the scale armor type anti-prick chip. Anti-prick devices like anti-prick clothes made of the scale armor type anti-prick chip can solve the problems that an existing protection device is overall heavy and poor in breathability, a protective layer is complex in structure, the production technology is complex, and cost is high. On the basis of the bionics principle, the scale armor of the crocodile is used for reference, the anti-prick chip structure is designed, and pyramid parts and columnar parts with the sector-shaped section are included. The pyramid parts are arranged in order, the chamfering treatment is carried out on the four side edges, the columnar parts are added between the adjacent pyramid parts, and various changes exist in the bottom face side lengths and the inclination angles of the pyramid parts. According to the anti-prick chip structure, the pricking and cutting functions of a cutter and other sharp instruments can be well scattered, the 24 J heavy punch impact generated when the pricking angle is 0 degree can be resisted, and good anti-prick performance is achieved. Meanwhile, the density of the structural face of the anti-prick chip is smaller than 7.5 kg / m<2>, and the scale armor type anti-prick chip is arranged in the anti-prick clothes so that the weight of the existing anti-prick clothes can be greatly reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

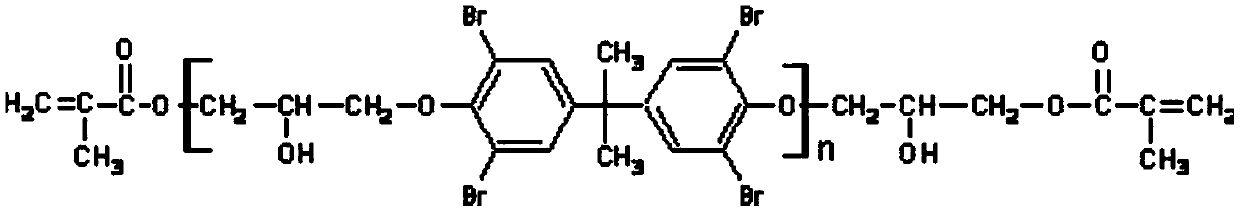

A kind of aramid fiber reinforced resin-based stab-resistant composite material

ActiveCN102632665BImprove structural strengthHigh hardnessSynthetic resin layered productsPersonal protection gearPolymer scienceResin matrix

The invention belongs to the technical field of an armored protecting material and relates to a human body protecting material technology, in particular to an anti-puncturing compound material. High strength and high modulus of aramid fiber plain cloth and high hardness of modified vinyl ester resin are utilized to resist the puncturing of a cutting tool. The aramid fiber reinforced resin based anti-puncturing compound material provided by the invention has an n-layer superposed structure of modified vinyl ester resin impregnated aramid fiber fabric sheet, wherein n is a natural number from 12-100; the surface density of the superposed structure is 4440-19000g / m<2>; the structure strength and hardness are high; the anti-puncturing property is excellent; the weight is light; the designability is strong; a shellproof effect is achieved; and the compound material is suitable for the field of human body protection and armoring protection.

Owner:SHANDONG NON METALLIC MATERIAL RES INST +1

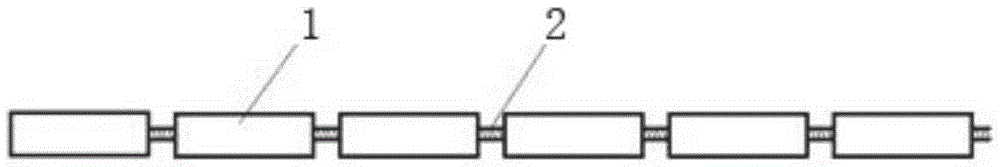

Flexible stab-resistant material and preparation method thereof

The invention discloses a flexible stab-resistant material and a preparation method thereof. The flexible stab-resistant material is composed of small protection modules and high-strength connecting members connecting the small protection modules. The high-strength connecting members are arranged among the small protection modules according to a certain order. The small protection modules are made from thermoplastic high molecular materials and high-property reinforced fiber in a combined mode, such as glass fibers, aramid fibers, chopped fibers of carbon fibers, nylon, and polycarbonate. The high-strength connecting members are made from high-strength high-modulus polyethylene, filaments, yarns or strands, and the filaments, the yarns or the strands are made from aramid fibers or carbon fiber materials. Gaps are formed among the small protection modules, so that the flexibility of the protection material is greatly improved. The invention further discloses a preparation method for forming the flexible stab-resistant material in an injection mode.

Owner:SUZHOU GAOJIA PROTECTION TECH CO LTD

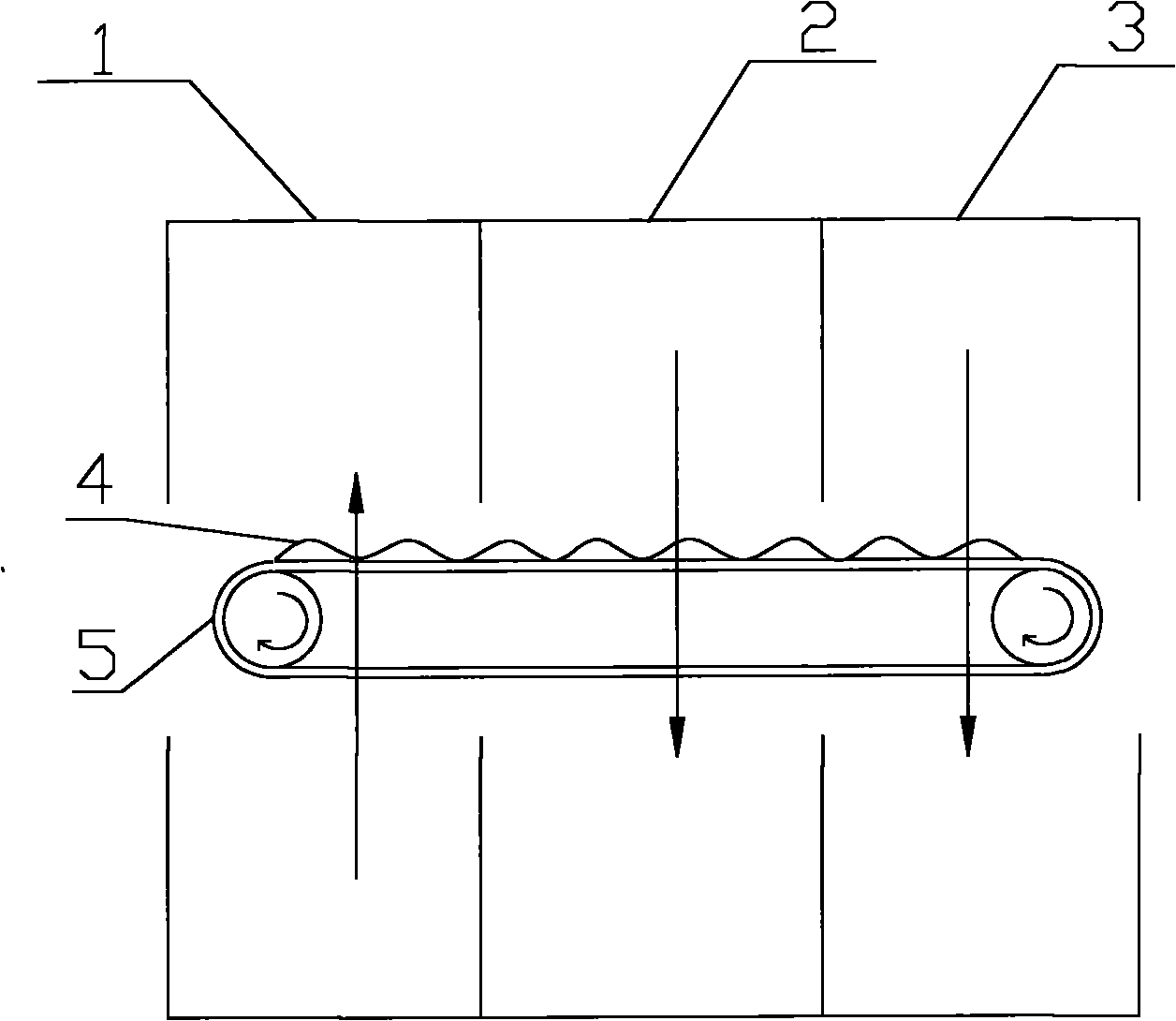

Method for preparing stab-resistant fabric

InactiveCN102116595AGood anti-stab performanceUniform mechanical propertiesPersonal protection gearPolymer scienceAdhesive

The invention provides a method for preparing a stab-resistant fabric, comprising the following steps: cutting a long fiber with the strength more than or equal to 25cN / detx into short fibers with the length of 50-100mm; loosing and carding the short fibers; overlapping the carded short fibers; carrying out needling on the overlapped short fibers to obtain a nonwoven fabric; gluing the nonwoven fabric by adhesive with the concentration of 6-15wt%, wherein the adhesive comprises 5-12wt% of polystyrene elastic body, 1-3wt% of thickening resin and the balance of solvent, and the content of the adhesive in the nonwoven fabric is 5-15wt%; and drying and carrying out hot-embossing on the glued nonwoven fabric, wherein the hot pressing temperature is 80-150 DEG C, and the pressure is 15-30MPa. In the method provided by the invention, high-strength fibers are taken as a raw material, and the adopted adhesive has better fluidity, thus the stab-resistant fabric prepared by adopting the method has uniform mechanical properties and better stab resistance.

Owner:杨珍芬

Stab-resisting cloth with inorganic powder coating and preparing method of stab-resisting cloth

InactiveCN106767165AGood flexibilityExcellent comfort and flexibilityPersonal protection gearFiberPolyresin

The invention discloses stab-resisting cloth with an inorganic powder coating and a preparing method of the stab-resisting cloth. The stab-resisting cloth comprises the inorganic powder coating and base cloth. The inorganic powder coating and the base cloth are stuck through an adhesive layer. Inorganic powder in the inorganic powder coating is ceramic powder. The prepared finished slab-resisting cloth with the inorganic powder coating is a soft non-metal stab-resisting product and has good stab-resisting performance, the face density of a stab-resisting material of the stab-resisting cloth is reduced by 20% than that of a resin fiber composite material of the same base cloth, the overall thickness and weight are reduced to a great degree, and the service life of the stab-resisting material of the stab-resisting cloth is prolonged by 50% or above than that of a stab-resisting material containing metal. In addition, the prepared stab-resisting cloth has better softness, and the comfortable and flexible degree is better when the stab-resisting cloth is made into stab-resisting clothes to be worn.

Owner:江苏安卡新材料科技有限公司

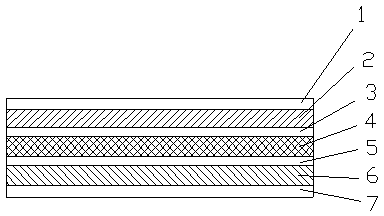

Novel puncture-proof clothing fabric

InactiveCN103462276AGood anti-stab performanceMeet protection needsSynthetic resin layered productsGlass/slag layered productsPolyesterYarn

The invention discloses a novel puncture-proof clothing fabric. The novel puncture-proof clothing fabric comprises an outer fabric layer, an outer puncture-proof layer, a first insulation layer, a middle buffer layer, an inner puncture-proof layer and an inner fabric layer which are sequentially arranged from outside to inside. The outer puncture-proof layer is woven from first high-strength yarn, wherein the first high-strength yarn comprises carbon fiber and high-strength polyester yarn; the middle buffer layer is a glass fiber filling layer; the inner puncture-proof layer is woven from second high-strength yarn, wherein the second high-strength yarn comprises aramid fiber and high-strength polyester yarn. Therefore, the novel puncture-proof clothing fabric has good puncture-proof performance and can meet the protection requirements of various industries.

Owner:WUXI TIANHONG MACHINERY MFG

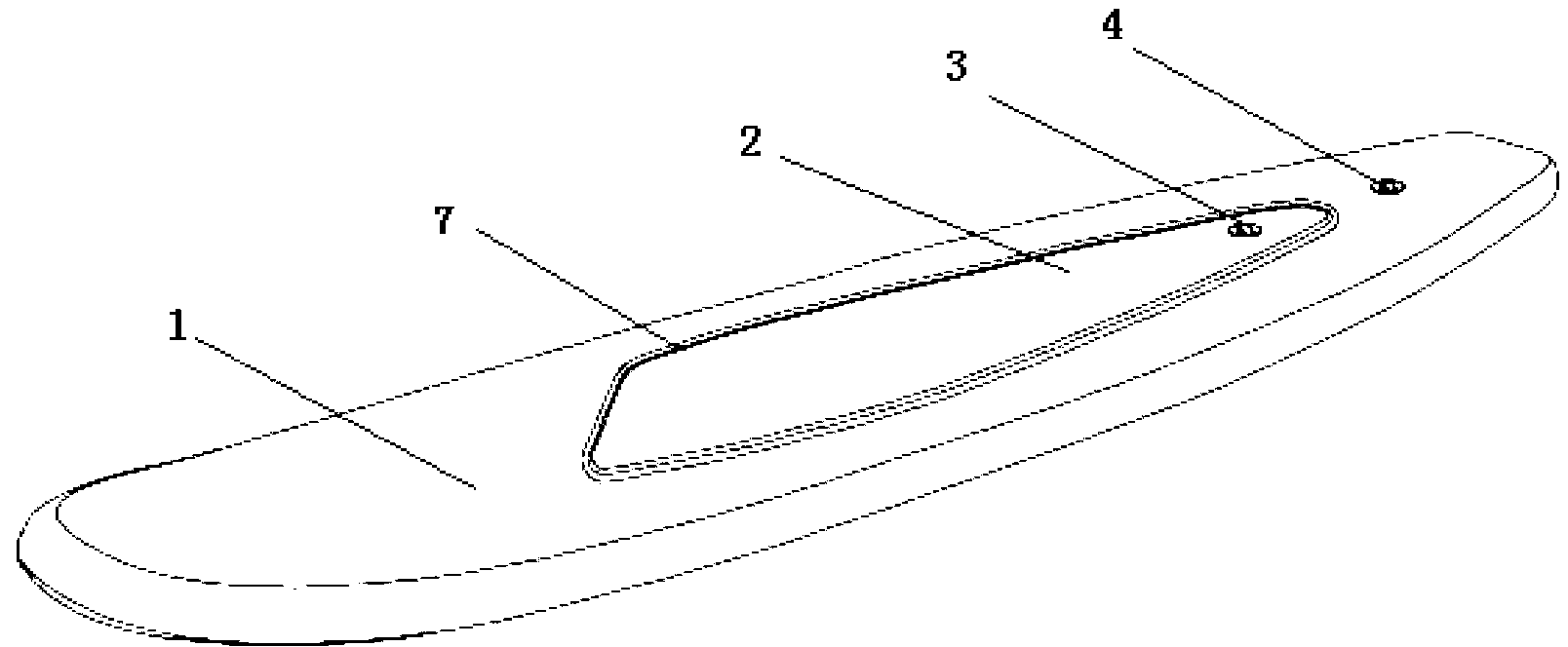

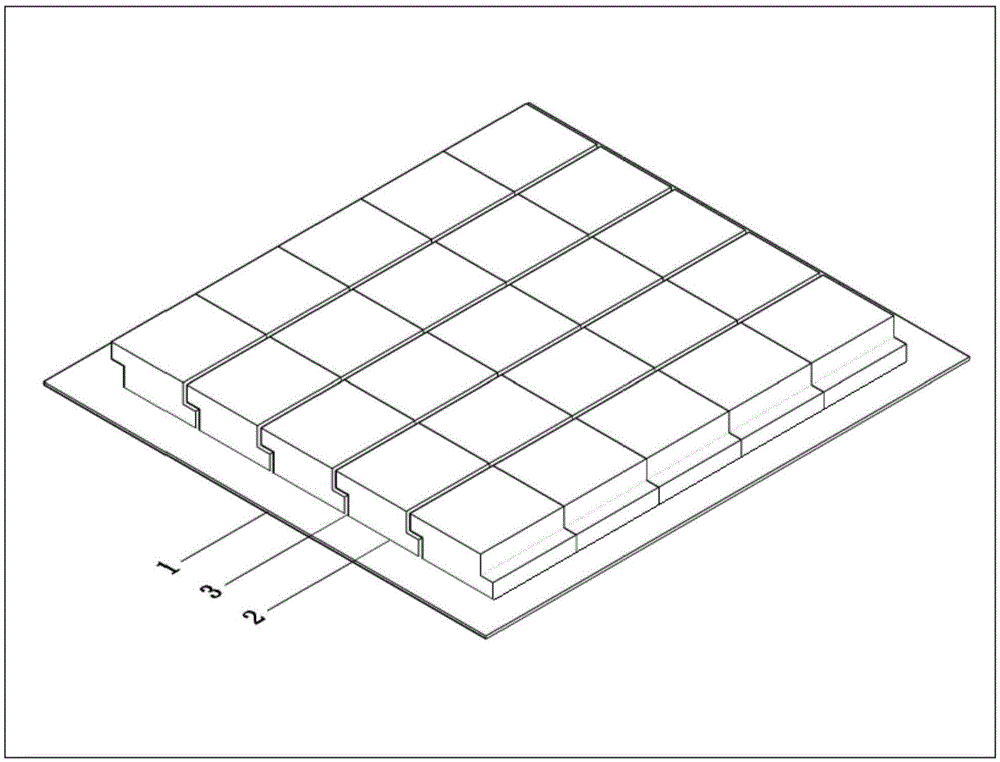

Multi-air-chamber surfboard made of double wall fabric and manufacturing method thereof

ActiveCN103264762AEnsure water safetyNo air leaksWaterborne vesselsSpecial purpose vesselsEngineeringShore

The invention discloses a multi-air-chamber surfboard made of double wall fabric and a manufacturing method thereof. The surfboard comprises a surfboard body provided with two or more than two air chambers. Each air chamber is provided with an aerating plug. The air chambers are connected through annular material pieces and meanwhile separated through separation belts. The annular material pieces are arranged in parallel on the upper lateral edges and the lower lateral edges of separation belts. The surfboard body is made of the double wall fabric. The surfboard is divided into a plurality of independent air chambers. In use, when any one of the air chambers is subjected to air leakage or damaged and broken, buoyancy of other air chambers can still bear the weight of a surfer who can be ensured to return to a shore safely, and personal safety of the surfer can be ensured.

Owner:SHANGHAI JILONG SPORT & LEISURE PROD CO LTD

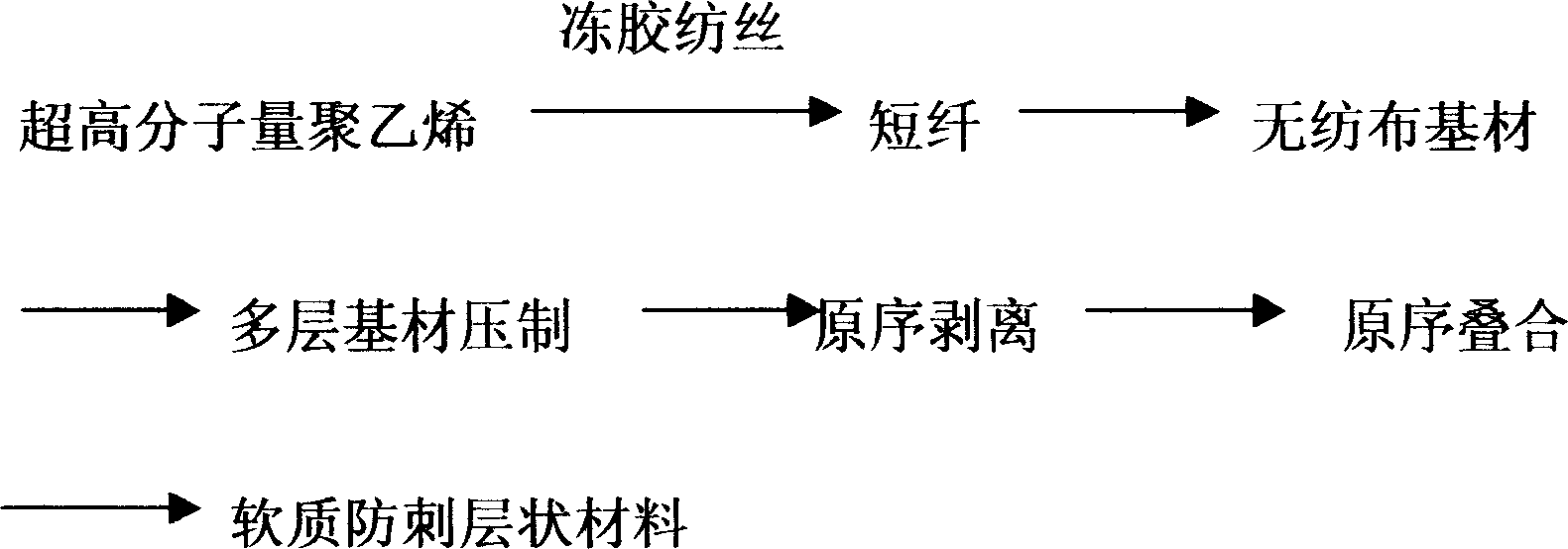

Soft prick-preventing layer material and its prepn and use

ActiveCN1672917AGood anti-stab performanceGood flexibilityLayered productsNonwoven fabricMaterials science

The soft prick-preventing layered material consists of several layers of non-woven fabric and capable of sliding relatively. Several layers of non-woven fabric of ultrahigh molecular weight polyethylene fiber are produced through pressing, layer-by-layer stripping and superposing into the prick-preventing material with interlayer sliding. The soft prick-preventing layered material of the present invention is light, soft, comfortable and excellent in preventing dynamic pricking, so that it may be used in making prick-preventing suit, explosive eliminating suit, anti-explosive sheet, explosion-preventing wall, etc.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

Composite material for bulletproof helmet and preparation method thereof

InactiveCN103600536AGood bulletproofLight in massSynthetic resin layered productsLaminationPolyresinHot pressing

The invention relates to a composite material for a bulletproof helmet and a preparation method thereof and belongs to the technical field of articles for body protection. The composite material is prepared by alternatively stacking an aramid weftless cloth layer and a resin layer and carrying out mold pressing; the composite material comprises the following materials in percentage by weight: 70-90% of aramid weftless cloth layer and 10-30% of resin layer. The disclosed preparation method of the composite material comprises the following steps: cutting the aramid weftless cloth according to the shape and size of the needed helmet; alternatively stacking the aramid weftless cloth layer and the resin layer, putting the obtained product into a common hot-pressing preforming mold and carrying out thermosetting mold pressing so as to soften the resin layer for alternative bonding with the aramid weftless cloth layer, thereby preparing a composite material blank for the bulletproof helmet; taking out the blank from the hot-pressing preforming mold, and then putting the blank into a cold-pressing preforming mold for cold-setting mold pressing, thereby obtaining the composite material for the bulletproof helmet. The bulletproof helmet prepared by the composite material is good in bulletproof performance and light in weight.

Owner:浙江帅孚安全科技有限公司

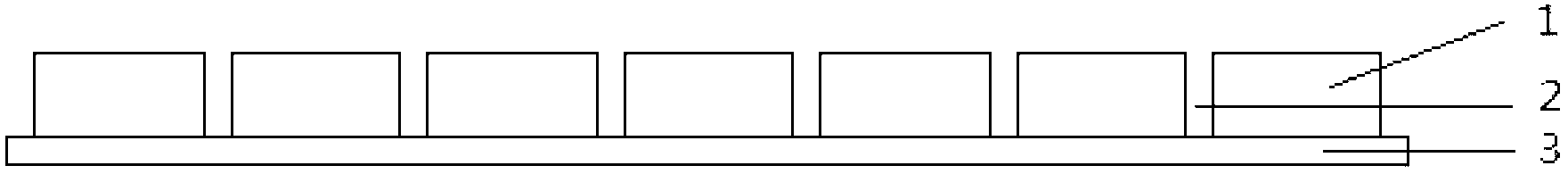

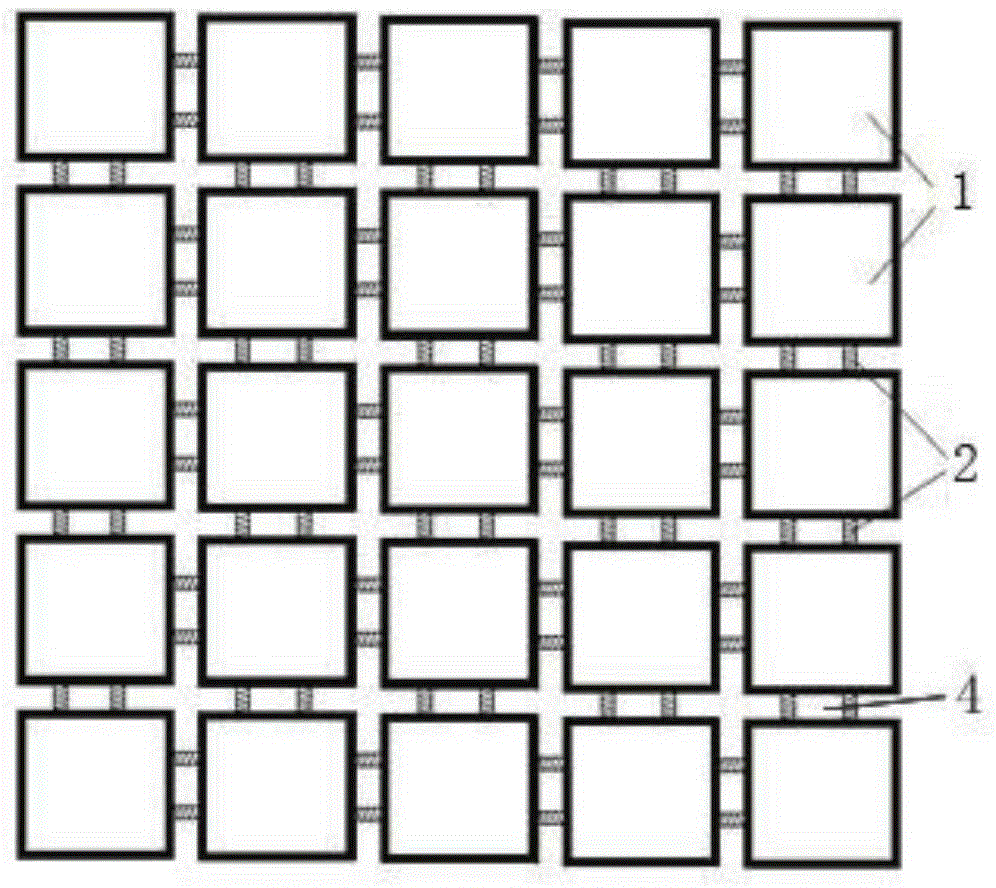

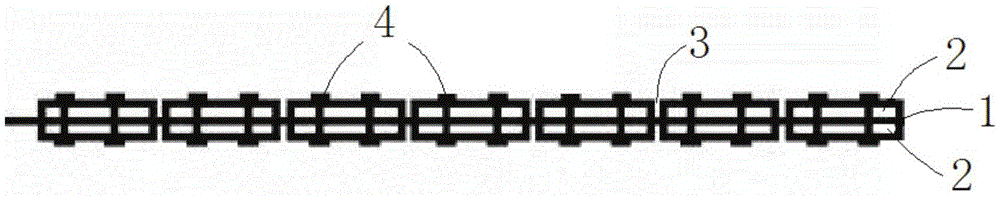

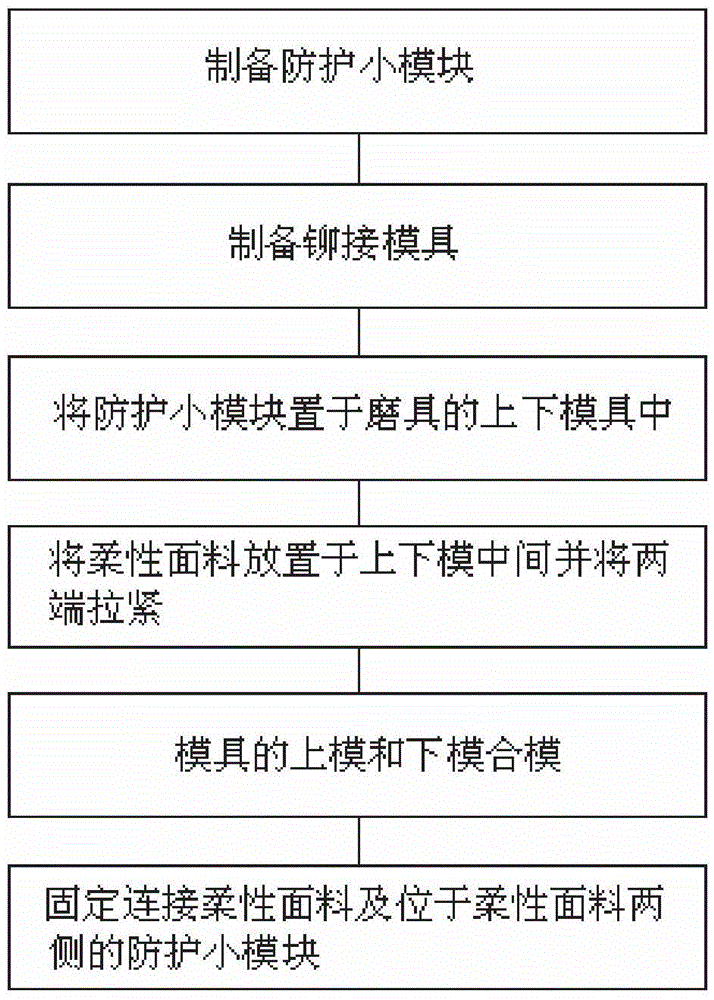

Two-surface-riveted flexible stab-resistant material and preparation method thereof

The invention discloses a two-surface-riveted flexible stab-resistant material and a preparation method thereof. The two-surface-riveted flexible stab-resistant material comprises flexible shell fabric and a plurality of small protective modules fixedly arranged on two sides of the flexible shell fabric in a two-surface-riveted mode. The multiple small protective modules are arranged according to a certain sequence, and gaps exist between the adjacent small protective modules. The flexible shell fabric is woven by a chemical fiber material or high-strength and high-modulus material and used for tightly connecting the small protective modules on the two sides. The small protective modules are made of thermoplastic reinforced composite materials or metal materials. The invention further discloses the preparation method for the two-surface-riveted flexible stab-resistant material. Stab-resistant garments and protective articles of various styles can be processed through the two-surface-riveted flexible stab-resistant material, the stab resistance of the stab-resistant material is improved, and the softness of the stab-resistant material is also improved to the maximum extent.

Owner:SUZHOU GAOJIA PROTECTION TECH CO LTD

Soft anti-penetrating material based on modified ultrahigh molecular weight polyethylene fiber and preparation method of soft anti-penetrating material

ActiveCN110183841AImprove surface hydrophilicityChange performanceNon-macromolecular adhesive additivesFibre typesFiberShell molding

The invention relates to a soft anti-penetrating material based on a modified ultrahigh molecular weight polyethylene fiber and a preparation method of the soft anti-penetrating material. The preparation method comprises steps of modification of an ultrahigh molecular weight polyethylene fiber, preparation of a three-dimensional woven prefabricated part, vacuum assistant compounding molding and drying curing. The step of modification comprises radiation grafting modification and dopamine modification, the surface hydrophilicity of the UHMWPE (ultrahigh molecular weight polyethylene), and the compatibility and the adhesiveness of the UHMWPE with a resin substrate composite system are effectively improved, the resin substrate composite system is prepared from a thermoplastic polyurethane elastomer solution and a shearing thickening liquid through compounding, and the resin substrate composite system is compounded with the three-dimensional woven prefabricated part in a vacuum assistant resin transferring molding mode. The soft anti-penetrating material has anti-penetrating properties meeting the standard GA68-2008, can be widely applied to fields of police security departments (suchas polices and prison guards) and civil fields (such as sports protection of fencing and the like, industrial protection of decoration, construction and the like, and security protection of taxi drivers and motorcycle racing drivers), and has very good development prospects.

Owner:QUANZHOU MAITEF TEXTILE TECH

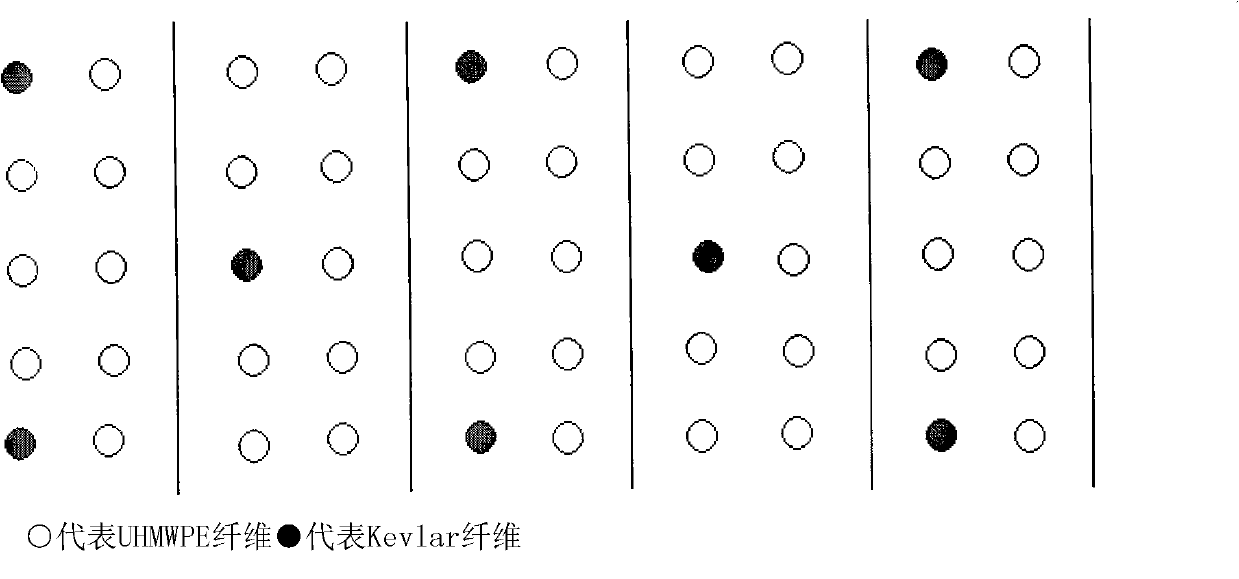

Novel three-dimensional orthogonal woven hybrid puncture-proof clothes

InactiveCN102485989AResistance to stretchingResistance to shearing and other forcesWoven fabricsProtective garmentFiberEngineering

The invention relates to a novel three-dimensional orthogonal woven hybrid puncture-proof clothes which is a mixture of ultra-high molecular weight polyethylene (UHMWPE) fiber and Kevlar fiber and is formed by interweaving in a three-dimensional orthogonal structure. Compared with the traditional puncture-proof clothes, the novel three-dimensional orthogonal woven hybrid puncture-proof clothes is interleaved from the mixture of UHMWPE fiber and Kevlar fiber, and thus the excellent puncture-proof performance and wearability of the material are ensured; and meanwhile, as a three-dimensional orthogonal weaving processing method, the material weight is greatly reduced, and the production cost of the material is lowered. The development of the three-dimensional orthogonal woven hybrid puncture-proof clothes lays foundation for the development of clothes toward light weight, low cost and flexibility.

Owner:JIANGNAN UNIV

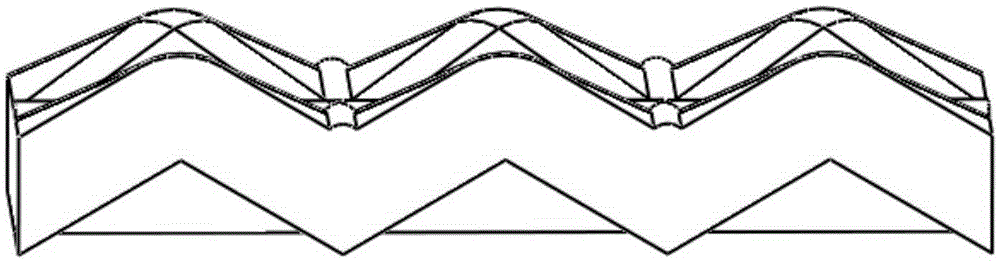

Z-shaped resin molding flexible puncture-proof fabric and preparation method thereof

ActiveCN105544228AGood anti-stab performanceHigh unit price ratioFibre treatmentPolyresinHot-melt adhesive

The invention relates to a Z-shaped resin molding flexible puncture-proof fabric and a preparation method thereof, the fabric is composed of a garment fabric body and cured Z-shaped resin, and the Z-shaped resin cured materials are pasted to the surface of the garment fabric body through hot melt adhesive according to rules. The preparation method includes the steps that the Z-shaped resin cured materials are obtained through a 3D printing technology or an injection-molding technology; hot melt adhesive powder is evenly spread on the garment fabric body, the Z-shaped resin cured materials are neatly arranged on the garment fabric body, then baking and drying are conducted, the surfaces of the Z-shaped resin cured materials are pressed, and the Z-shaped resin molding flexible puncture-proof fabric is obtained. The Z-shaped resin molding flexible puncture-proof fabric has the advantages that weight is reduced, and the fabric is comfortable to wear, flexible and the like; the preparation method is low in cost and wide in raw material source, and the prepared puncture-proof fabric overcomes defects of the prior art and meets requirements of the military field and the civil fields.

Owner:DONGHUA UNIV

Hard puncture-proof material and preparation method thereof

InactiveCN108237747AGood anti-stab performanceNot easy to pierceLamination ancillary operationsSynthetic resin layered productsGlass fiberPolyresin

The invention discloses a hard puncture-proof material which is prepared by compounding and pressing multiple single-direction continuous glass fiber enhanced thermoplastic prepreg tapes 0 / 90-degree plied or is prepared by compounding and pressing two 0 / 90-degree composite materials and a thermoplastic light cutting board, wherein each single-direction continuous glass fiber enhanced thermoplasticprepreg tape is a prepreg tap sheet prepared by fully immersing continuous glass fibers in thermoplastic resin; the 0 / 90-degree composite material is a sheet which is 0 / 90-degree plied and compoundedand pressed by multiple single-direction continuous glass fiber enhanced thermoplastic prepreg tapes or a sheet obtained by thermal pressing glass fiber cloth and a thermoplastic resin tubular product; the thermoplastic light cutting board is a glass fiber / resin mixed felt layer prepared by uniformly mixing the glass fibers and polypropylene fibers or glass fibers and polypropylene drawn wires and then carrying out unloosening treatment, carding forming, cross lapping, needling to obtain the felt and rolling. The hard puncture-proof material is good in puncture-proof effect, difficult to puncture, low in cost and light in weight.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

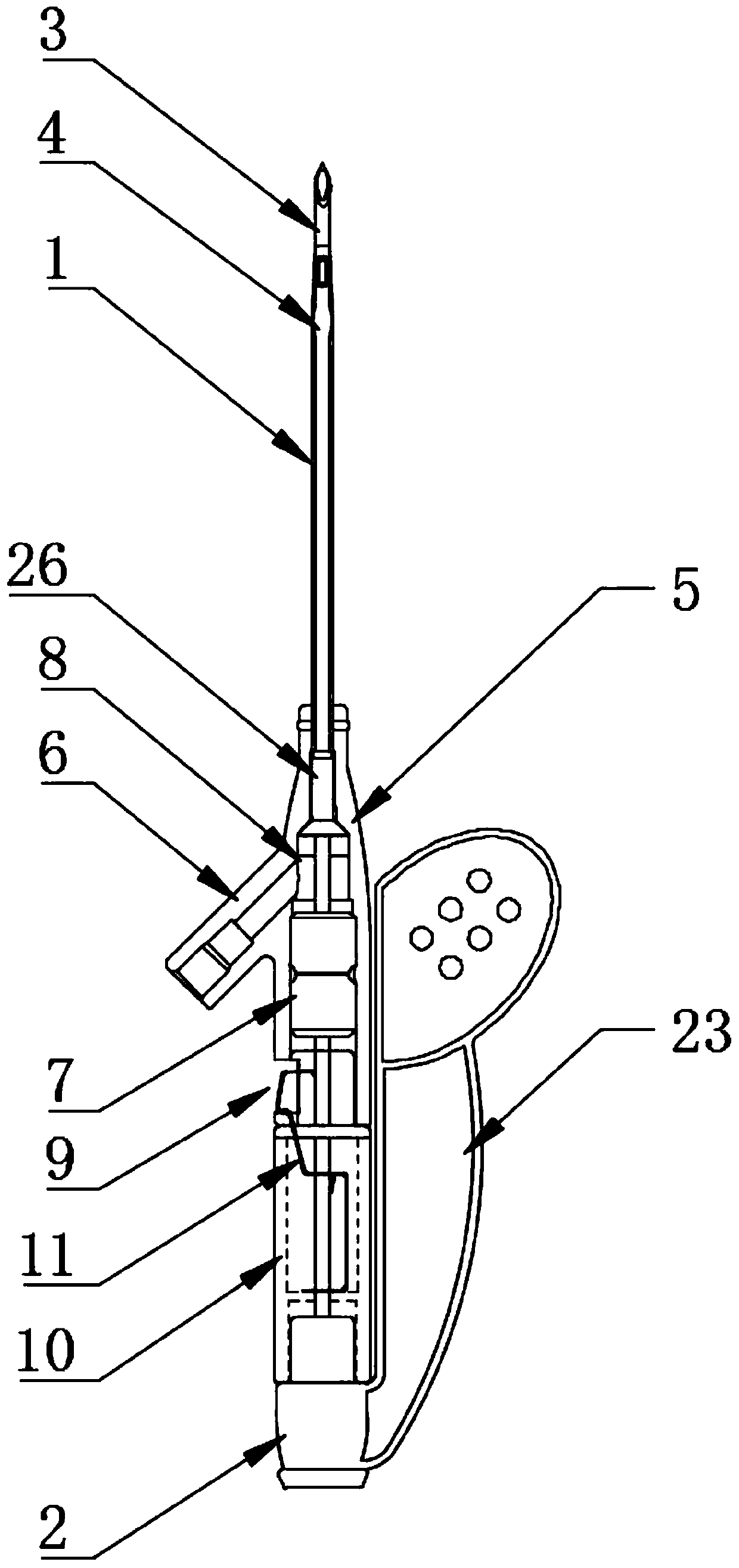

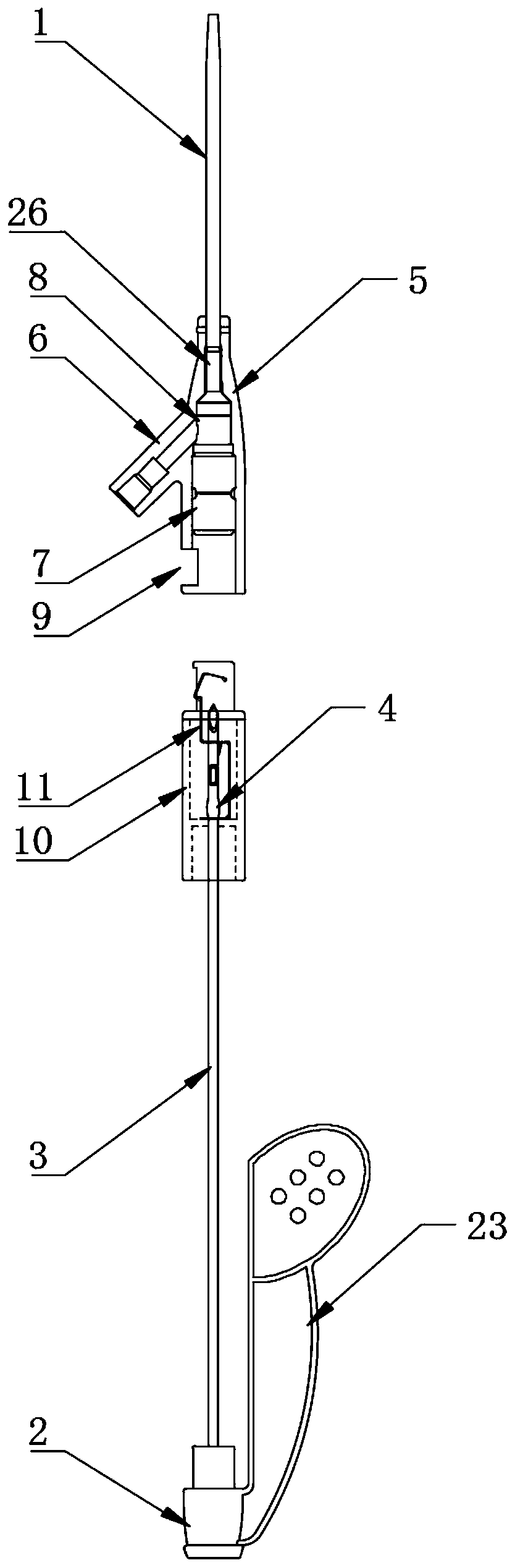

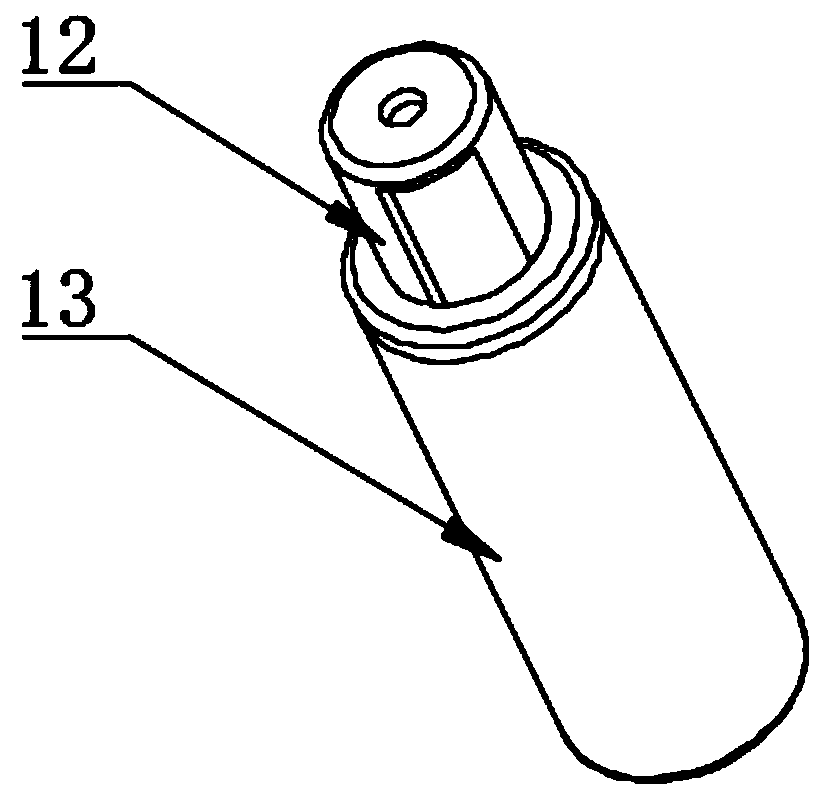

Anti-puncture remaining needle assembly

The invention provides an anti-puncture remaining needle assembly and belongs to the field of medical apparatus and instruments. The assembly comprises a puncture assembly, a hose holder, a hose and an anti-puncture assembly; a bulge with outer diameter larger than that of a steel needle is formed on the steel needle, and a notch is formed in the side edge of the hose holder; an elastic piece baseis a tubular base provided with an opening in the bottom, an elastic piece groove in the side part and an elastic piece baffle at the top, a partition is fixedly mounted in a sleeve, and steel needlepassing holes with outer diameter larger than outer diameter of the bulge are formed in the elastic piece baffle and the partition; a propping piece propped against the outer wall of the steel needleis fixed on an anti-puncture elastic piece, and the steel needle is enabled to lean against the inner side of the anti-puncture elastic piece; the elastic piece base is sleeved with the sleeve, and the anti-puncture elastic piece is mounted in the elastic piece groove and the sleeve; the elastic piece base is inserted into the hose holder, and the anti-puncture elastic piece bulges out of the elastic piece groove and is clamped at the notch in a hanging manner. The anti-puncture remaining needle assembly which can be used for storing and protecting the steel needle during needle withdrawal issimple in structure, convenient to mount and good in anti-puncture effect.

Owner:JIANGSU SUYUN MEDICAL MATERIALS

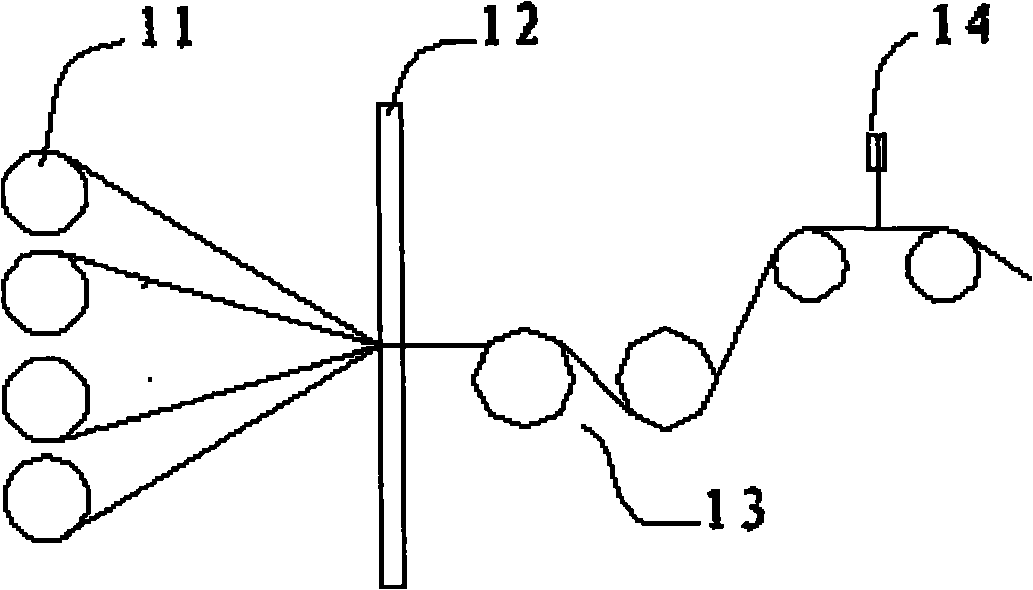

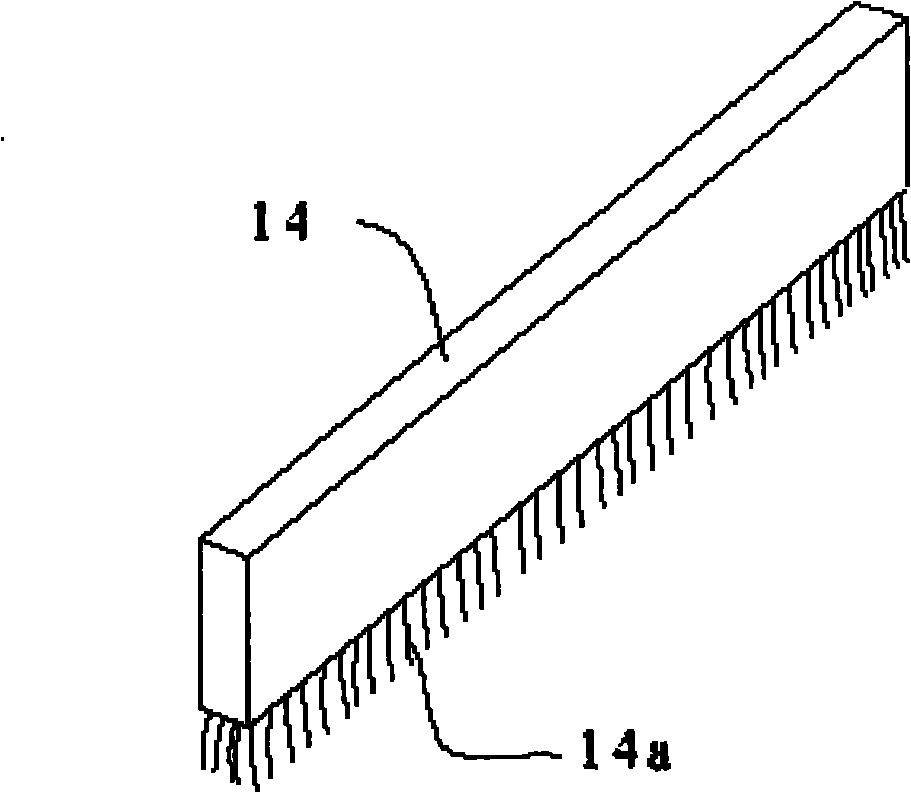

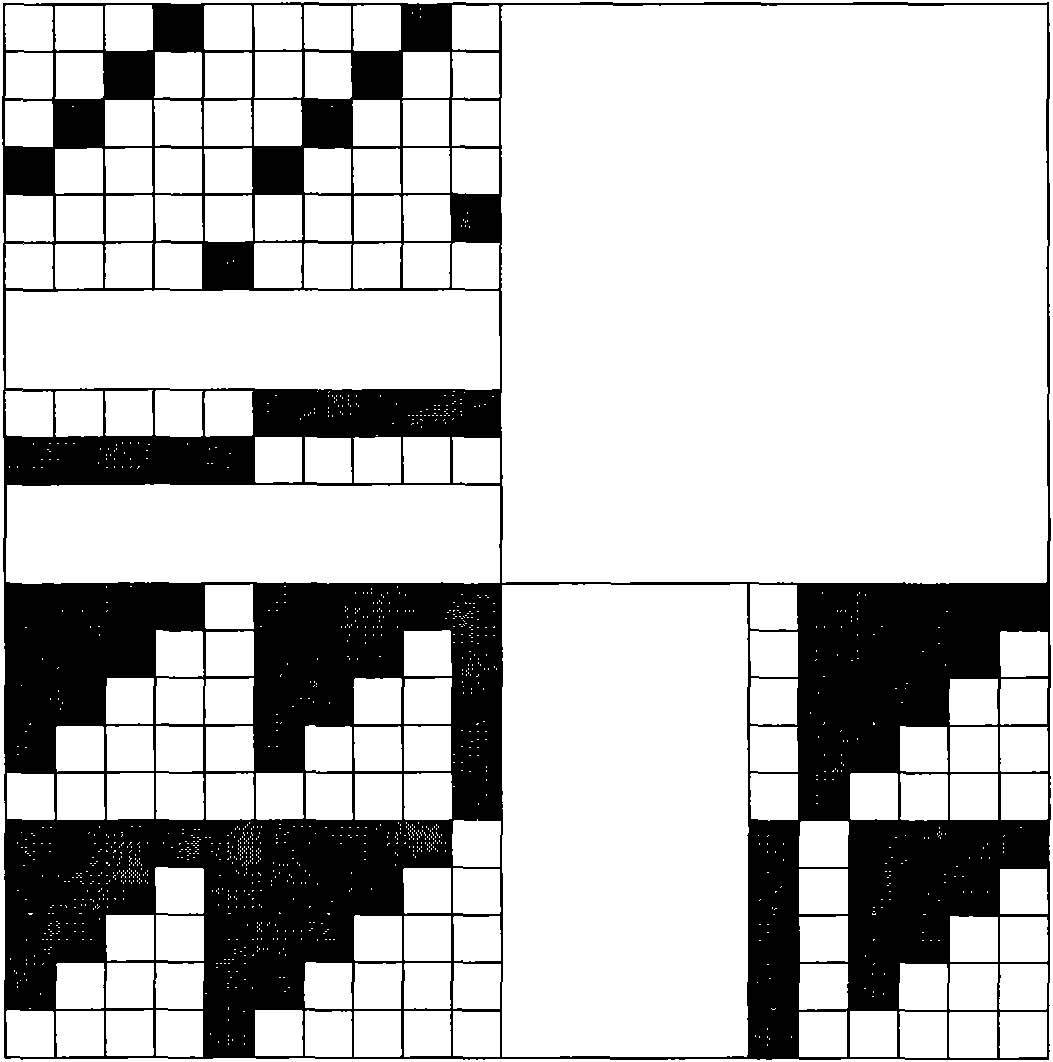

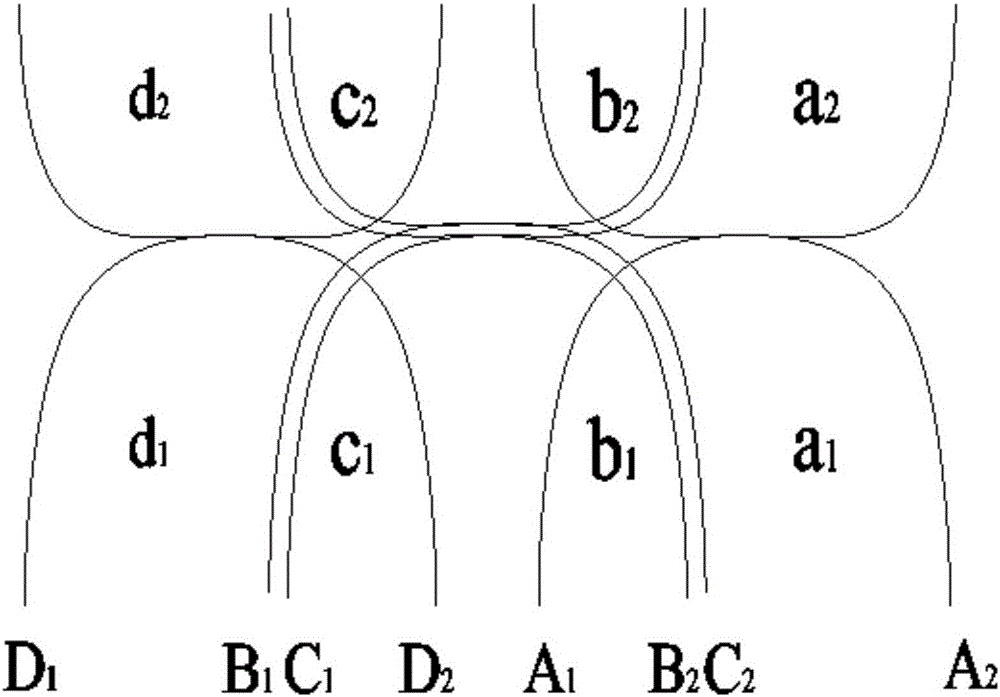

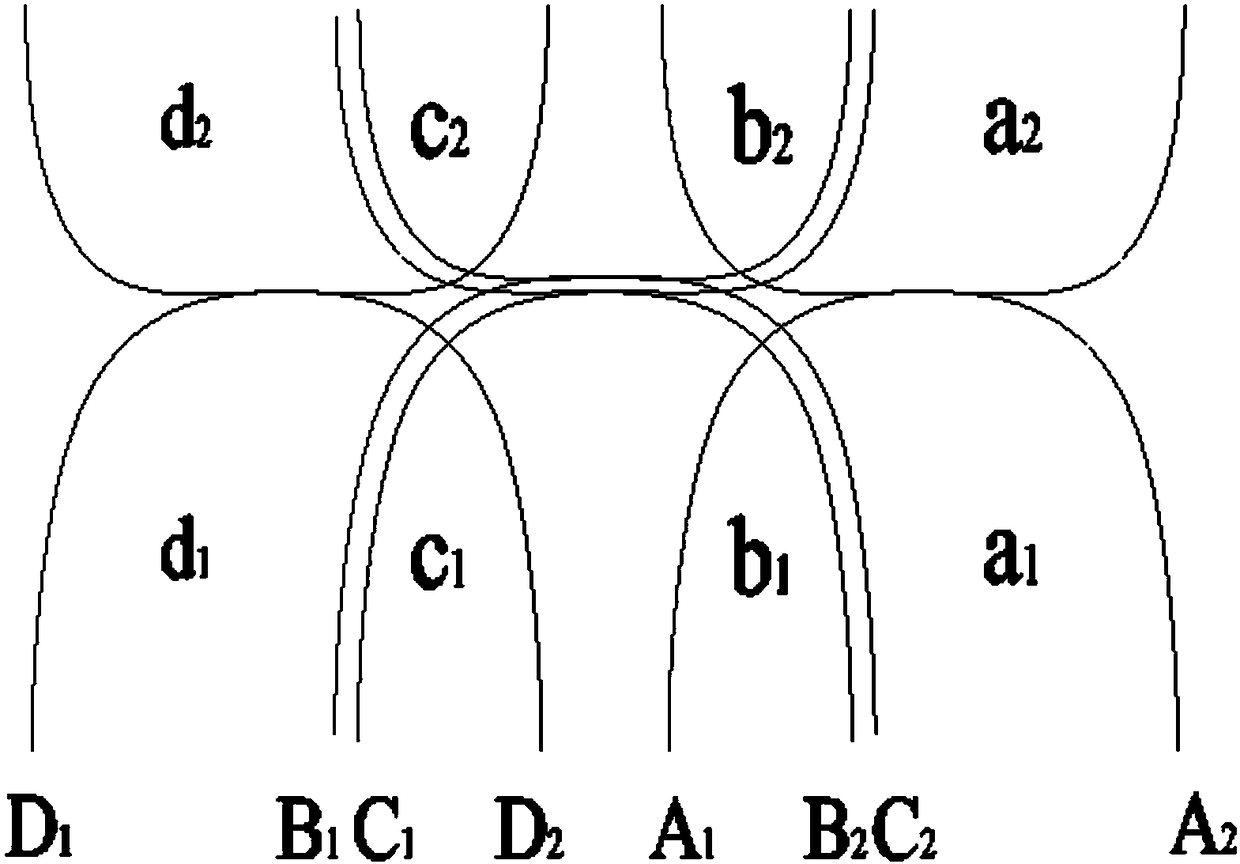

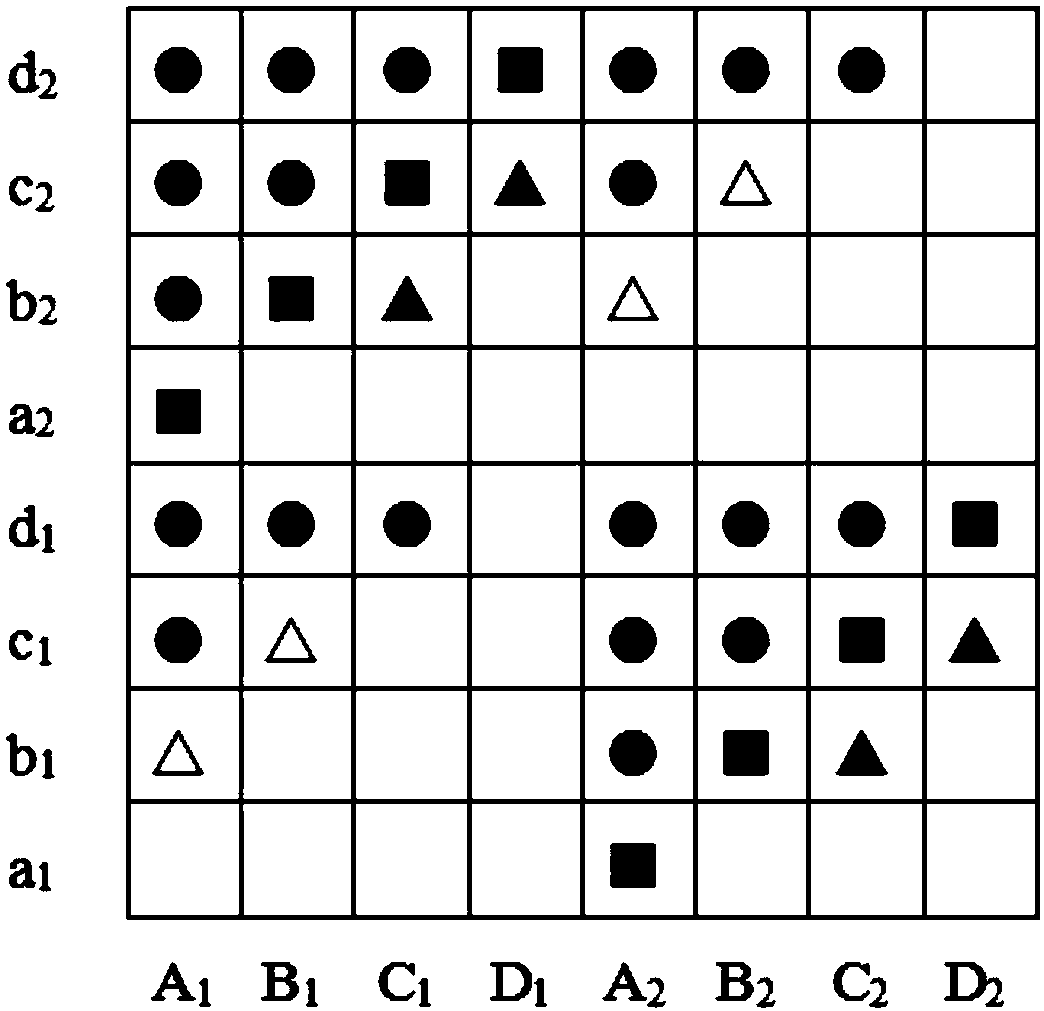

Multi-layer multi-raw material flexible stab-resistant fabric and a weaving method therefor

InactiveCN106120081AImprove stab resistanceGood anti-stab performanceMulti-ply fabricsPolyesterEngineering

The invention provides multi-layer multi-raw material flexible stab-resistant fabric comprising four layers. Each layer of the fabric is a plain weave and the layers are connected mutually, so that the stab-resistant requirement is met; the fabric is light, soft and efficient and the problem of insufficient comfort of conventional stab-resistant fabric is solved. The invention also provides a weaving method for the multi-layer multi-raw material flexible stab-resistant fabric, and the method employs a multi-warp beam rapier loom for weaving. The method comprises a first step of warping: ultra-high molecular weight polyethylene filaments, which are the raw materials for weaving the first layer, are wound around a weave beam, high-tenacity polyester filaments, which are the raw materials for weaving the second layer and the third layer, are wound around a second weave beam, and aramid fibers, which are the raw materials for weaving the fourth layer, are wound around a third weave beam; a second step of performing drafting by using a straight draft method; a third step of weaving; a rapier sample loom is used for weaving, and during weaving, the humidity control of warp yarn requires an environmental relative humidity of 70%-75%, and a protective twist of 80-100 twists / m is added to warp yarn.

Owner:XI'AN POLYTECHNIC UNIVERSITY

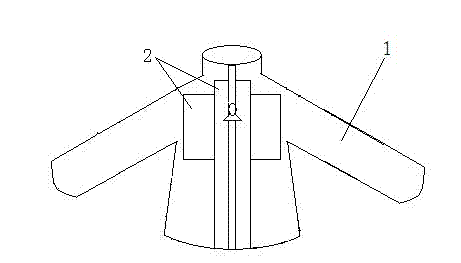

Novel cutting-preventive wear-resistant garment

InactiveCN103040159AStrong wear resistanceAnti-cutProtective garmentSpecial outerwear garmentsFiberWear resistant

The invention discloses a novel cutting-preventive wear-resistant garment which comprises a garment body and a garment cutting-preventive layer. The garment body comprises an inner garment layer and a garment wear-resistant layer, the inner garment layer is made of breathable fibers, the garment wear-resistant layer is made of high-wear-resistant fibers, the garment cutting-preventive layer is made of bulletproof fibers and Kevlar fibers, the garment wear-resistant layer is connected with and arranged outside the inner garment layer, and the garment cutting-preventive layer is connected with and arranged outside the garment body in a crossed manner. By the mode, the novel cutting-preventive wear-resistant garment has the advantages of high wear resistance, cutting prevention and good stab resistance and provides safety guarantee and convenience for people executing or implementing dangerous works.

Owner:WUJIANG JIESHENG TEXTILE FINISHER

Fireproof cable bundle

InactiveCN106601359AImprove securityAvoid spreadingInsulated cablesInsulated conductorsRubber materialEngineering

The invention relates to a fireproof cable bundle comprising an enclosed cover piece made of steel plates. A bunch pipe made of PVC materials is fixed in the middle of the enclosed cover piece; and the axial two ends of the bunch pipe penetrate the axial wall surfaces of the two ends of the enclosed cover piece. A flame-retardant cover piece is also arranged at the wall surface, corresponding to the internal segment of the enclosed cover piece, of the bunch pipe and is made of a polyformaldehyde material; a flame-retardant cavity is formed between the flame-retardant cover piece and the bunch pipe; annular flame-retardant layer formed by a plurality of column-shaped flame-retardant oil bags is arranged inside the flame-retardant cavity; and the flame-retardant oil bags are made of oil-resistant rubber materials and are filled with flame-retardant silicone oil. According to the fireproof cable bundle, a flame-retardant mechanism that can burst when a wire pipe burns to enable the flame-retardant silicone oil to fill the cable so as to realize a flame-retardant effect is arranged, so that security of the cable can be improved and fire spreading with the cable can be prevented.

Owner:CHINA SCI TIANGONG ELECTRICAL HLDG

Bullet-proof and puncture-proof material and manufacturing method thereof

ActiveCN111256539AEasy to prepareImprove efficiencyPersonal protection gearResin matrixMechanical engineering

The invention provides a manufacturing method of a bullet-proof and puncture-proof material. The method comprises the following steps that a) high-strength fiber is woven into fabric, wherein the strength of the high-strength fiber is greater than or equal to 20 cN / dtex, and the tensile modulus is greater than or equal to 700 cN / dtex; b) the fabric obtained in the step a) is subjected to surface treatment, gum dipping, drying and winding in sequence, and fabric prepreg is obtained, wherein gum used in the gum dipping process is a thermoplastic resin matrix; and c) the fabric prepreg obtained in the step b) is subjected to hot press setting, and after cooling, the bullet-proof and puncture-proof material is obtained. Compared with the prior art, the manufacturing method provided by the invention takes the high-strength fiber as the raw material, the specific process steps and conditions are adopted, a good interaction effect is achieved, and the obtained bullet-proof and puncture-proofmaterial has both the excellent bullet-proof performance and puncture-proof performance, and is light in weight and comfortable to wear. Experiment results show that the surface density of the bullet-proof and puncture-proof material provided by the invention is below 240 g / m<2>, in addition, bullet-proof and puncture-proof standard requirements are met at the same time, and the material can be applied as the base material of bullet-proof and puncture-proof products.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

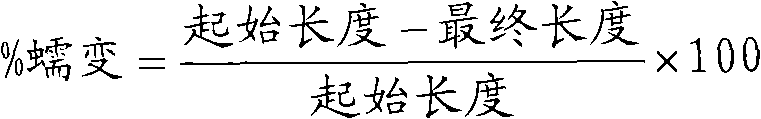

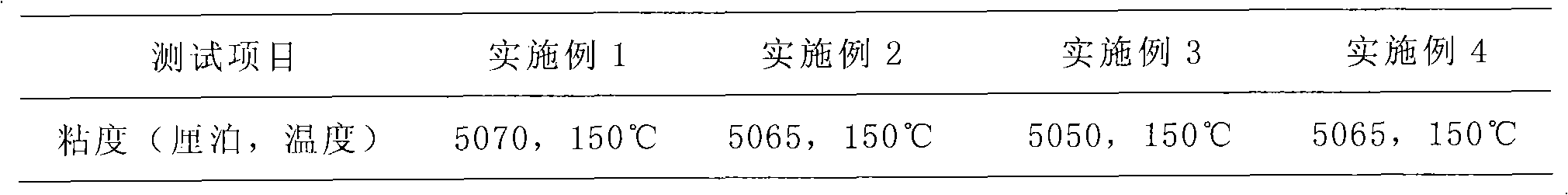

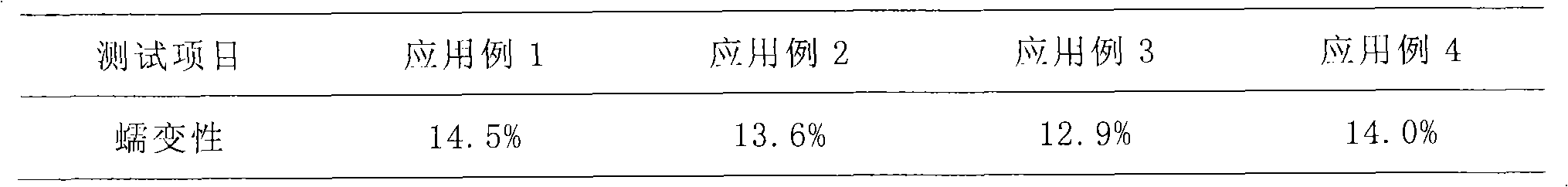

Adhesive used for preparing stab-resistant fabrics

InactiveCN102115651AGood anti-stab performanceImprove stab resistanceFibre treatmentHydrocarbon polymer adhesivesFiberElastomer

The invention provides an adhesive for preparing stab-resistant fabrics, which comprises 5 to 12 weight percent of polystyrene elastomer, 1 to 3 weight percent of tackifying resin, 0.5 to 1.2 weight percent of plasticizer, 1 to 3 weight percent of fire retardant and the balance of solvent. The adhesive contains the polystyrene elastomer and the tackifying resin which have good compatibility with superhigh molecular weight polyethylene fibers, and the bonding strength of the adhesive is improved; moreover, the adhesive also contains the plasticizer and the fire retardant, and the creep properties and the fire retardancy of the adhesive are improved; therefore, the prepared stab-resistant fabrics have better stab resistance, the fire retardancy of the stab-resistant fabrics is improved, and the application range of the stab-resistant fabrics is widened.

Owner:杨珍芬

Degradable PLA biological composite packaging material and preparation method thereof

InactiveCN109320782AReasonable ratioGood biodegradabilityFlexible coversWrappersVegetable fibersPolypropylene

The invention relates to the technical field of packaging materials and discloses a degradable PLA biological composite packaging material and a preparation method thereof. The degradable PLA biological composite packaging material is prepared from the following raw materials in parts by mass: 15 to 30 parts of starch, 15 to 25 parts of clay, 5 to 10 parts of float glue, 10 to 15 parts of vegetable fibers, 5 to 7 parts of an adhesion promoter, 3 to 7 parts of polylactic acid, 3 to 5 parts of polypropylene, 10 to 18 parts of carrageenan, 3 to 6 parts of sodium xylene sulfonate, 12 to 15 parts of gelatin, 5 to 7 parts of a plasticizer, 3 to 7 parts of an antioxidant, 2 to 4 parts of a coupling agent and proper amount of a foaming agent. According to the degradable PLA biological composite packaging material and the preparation method thereof, the problem that existing packaging materials have serious pollution to the environment can be solved.

Owner:JIASHAN TIANHUI GARMENT ACCESSORIES

Road buffer block and its application method

InactiveCN1443901AImprove wear resistanceGood anti-stab performanceTraffic signalsRoad signsEngineeringWear resistance

The present invention relates to a road buffer block and its application method. The buffer block can be mounted on two sides of road for absorbing and buffer impact force to protect car, fence and curb. The road buffer block includes blobk body said block body is made up by using rubber and fabric, and said fabric includes cotten thread, artificial silk, synthetic fibre and steel wire fabrics, also can adopt the existent cord fabric. The road buffer block has good wear resistance, prick resistance and anchoring property.

Owner:章晓东

Resin-free soft puncture-proof material

PendingCN111826772AImprove puncture resistanceHigh strengthLayered productsProtective fabricsYarnFiber

The invention provides a resin-free soft puncture-proof material, and relates to the technical field of protective equipment. The soft puncture-proof material provided by the invention comprises a cutting-proof layer and / or a puncture-proof layer, wherein when the soft puncture-proof material comprises the anti-cutting layer and the puncture-proof layer, the puncture-proof layer is overlaid on thesurface of one side of the anti-cutting layer; the anti-cutting layer is formed by overlaying 5-50 pieces of wrap yarn fabric; each piece of wrap yarn fabric is formed by plain weaving of one or morekinds of wrap yarns; the wrap yarns sequentially comprise core layers (Kevlar or UHMWPE fiber), first wrap yarn layers (PA or PU fiber) and second wrap yarn layers (Kevlar or UHMWPE fiber) from inside to outside; the puncture-proof layer is formed by overlaying 1-10 pieces of three-dimensional fabric; and the fiber material of each piece of three-dimensional fabric is UHMWPE fiber or Kevlar fiber. The soft puncture-proof material provided by the invention has the characteristics of light weight, softness, comfort in wearing and good puncture-proof effect.

Owner:NANTONG UNIVERSITY

Multi-layer multi-material flexible stab-resistant fabric and its weaving method

InactiveCN106120081BImprove stab resistanceGood anti-stab performanceMulti-ply fabricsPolyesterAramid

Owner:XI'AN POLYTECHNIC UNIVERSITY

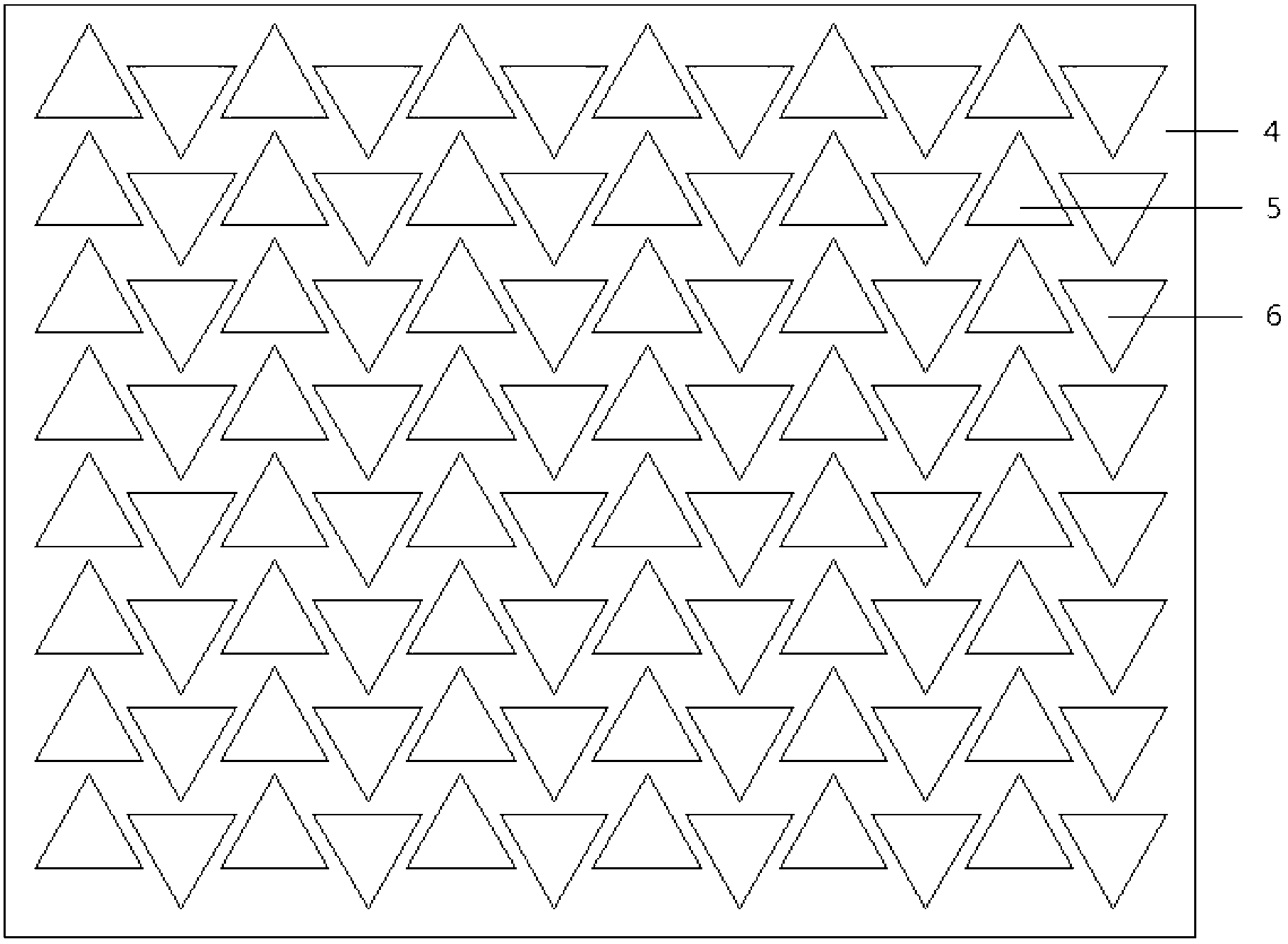

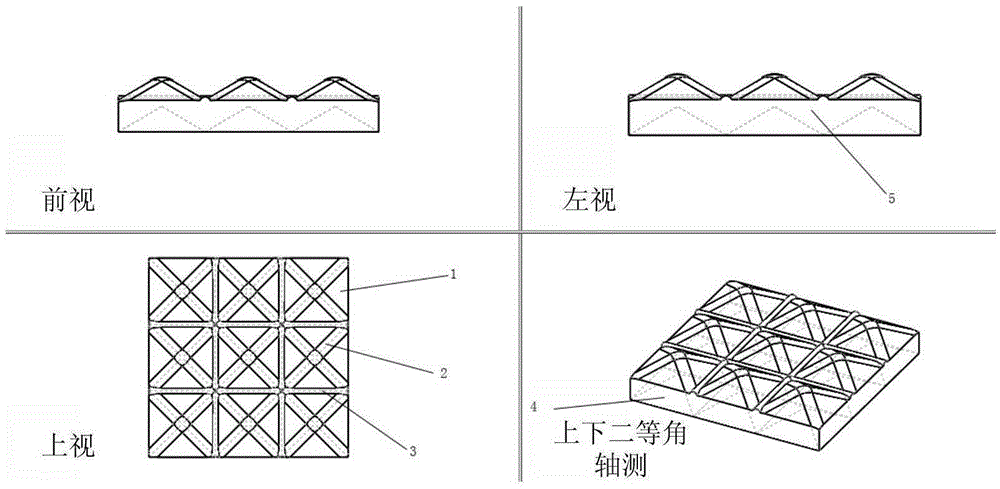

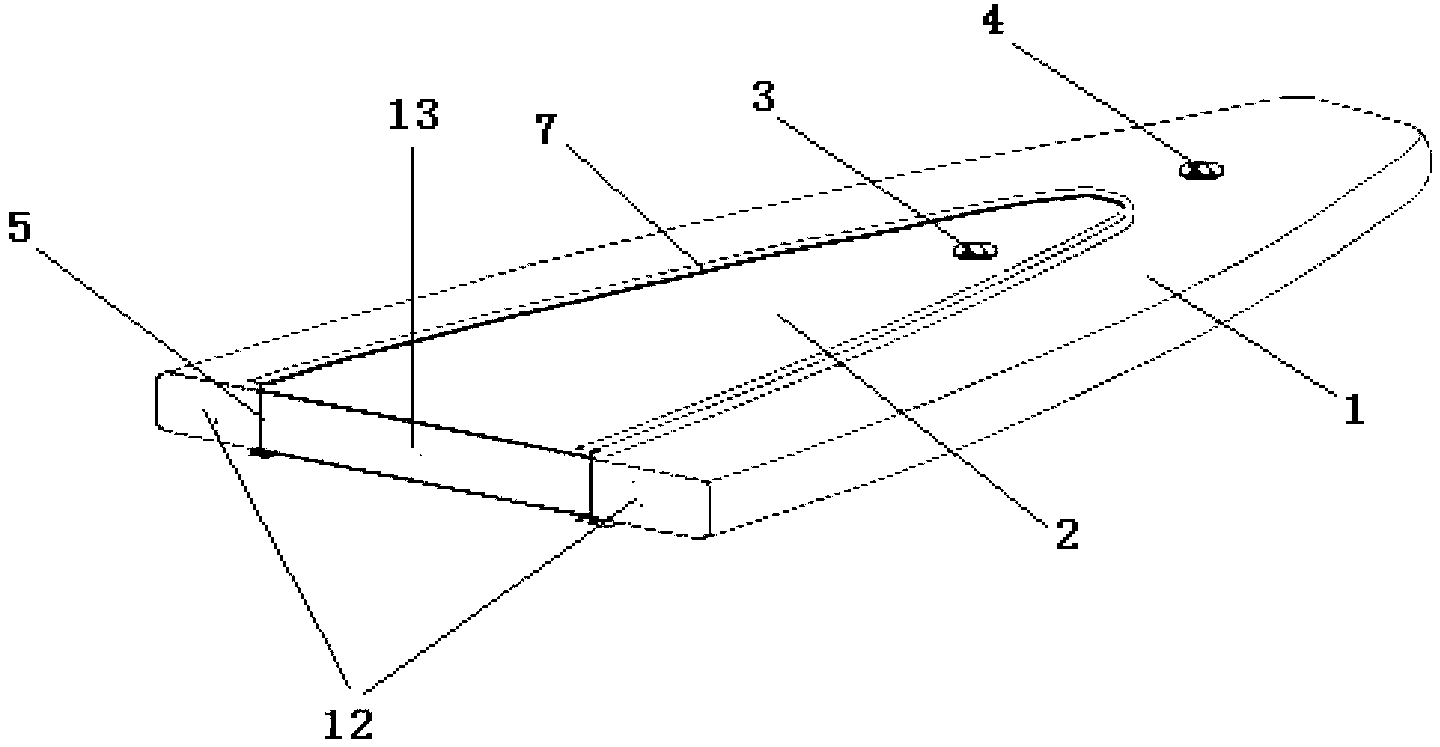

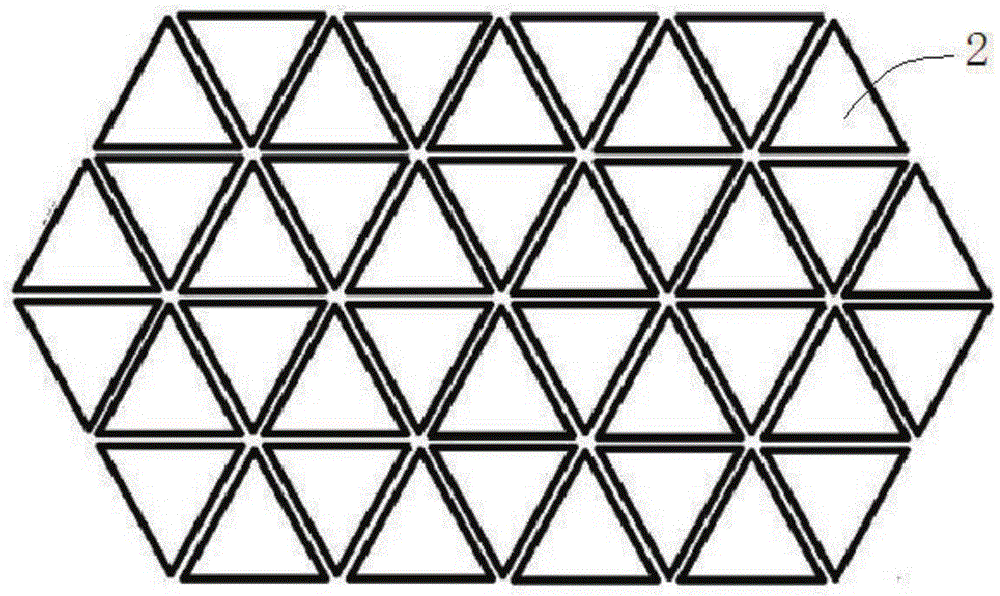

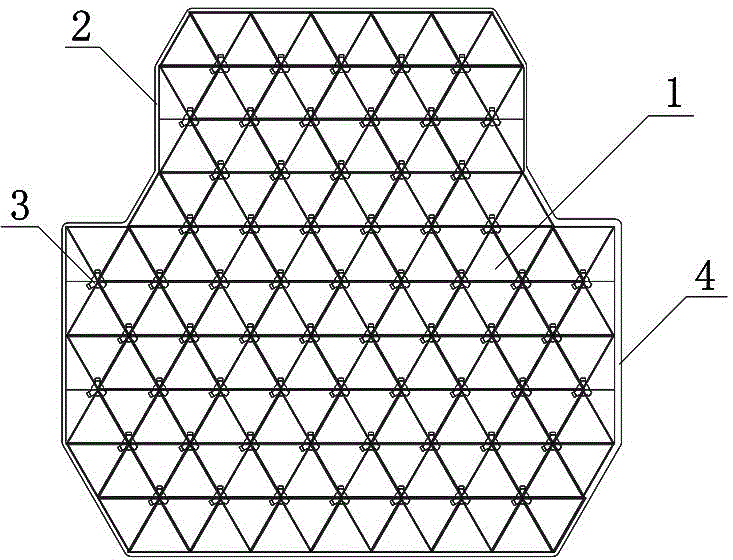

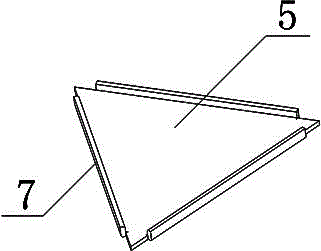

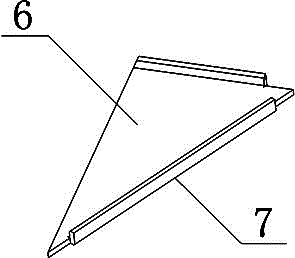

Lightweight anti-puncture garment

ActiveCN104897005ASimple structureFlexible and convenientPersonal protection gearVertical edgeEngineering

The invention relates to a lightweight anti-puncture garment. The lightweight anti-puncture garment comprises regular triangular plate assemblies (1), semi-triangular plate assemblies (2), buckle assemblies (3) and a wrapper (4), wherein a central part and a horizontal edge part of the anti-puncture garment are buckled by a plurality of regular triangular plate assemblies (1); buckling edges (7) of every two adjacent regular triangular plate assemblies (1) are buckled; clamping jaws (9) of each buckle assembly (3) are clamped into a clamping groove formed by buckling the corresponding six regular triangular plate assemblies (1) with common vertexes; a vertical edge part of the anti-puncture garment is composed of a plurality of semi-triangular plate assemblies (2); a buckling edge (7) at an inclined edge of each semi-triangular plate assembly (2) is buckled with the corresponding buckling edge (7) of the nearest regular triangular plate assembly (1); buckling edges (7) at short right-angled edges of every two adjacent semi-triangular plate assemblies (2) are buckled with each other. The lightweight anti-puncture garment has the advantages that an alignment buckling structure is adopted, the lightweight anti-puncture garment is flexible and convenient after being worn, the anti-puncture effect is good, and the production cost is low.

Owner:CHENGDU JINAN EQUIP

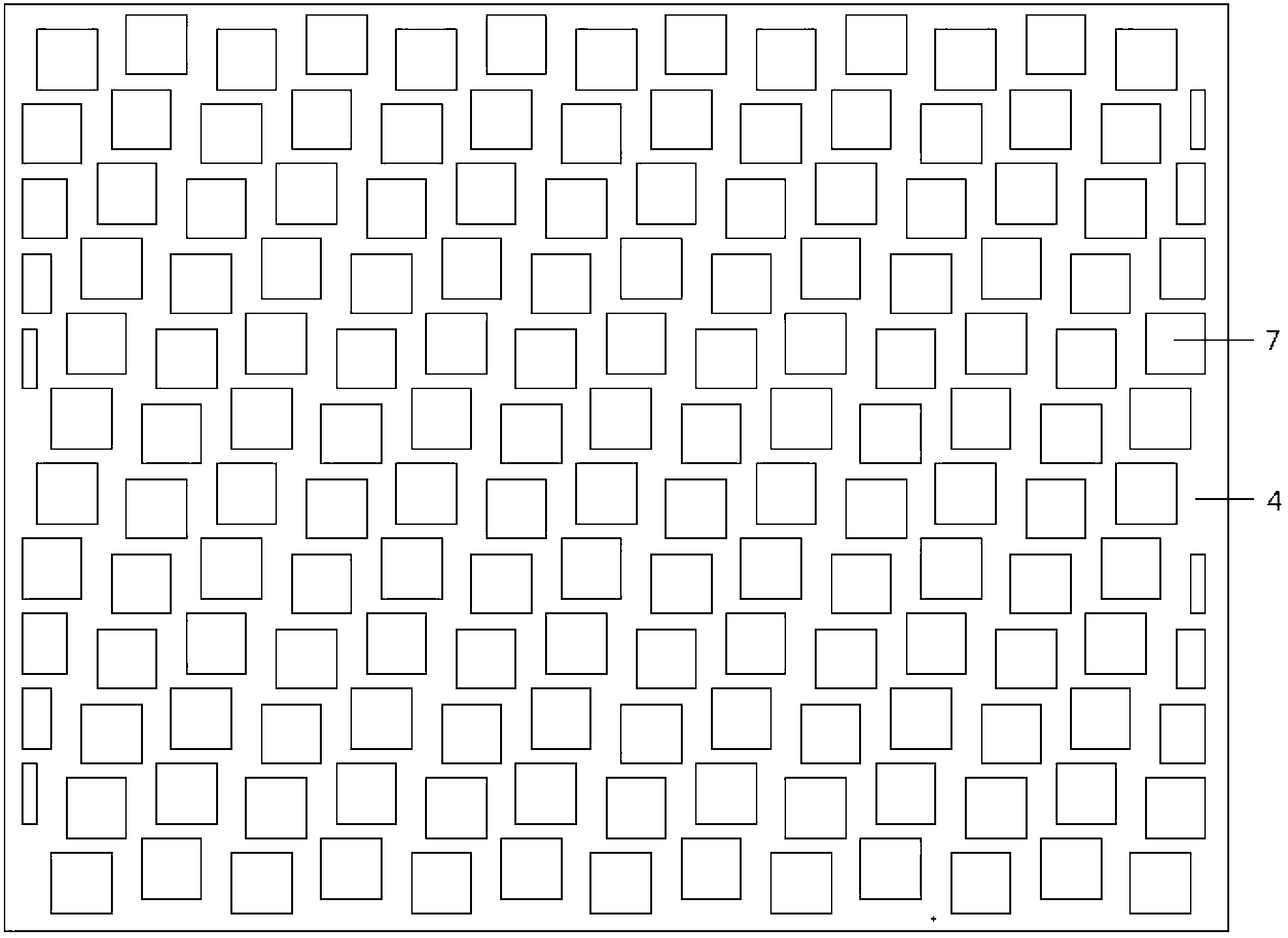

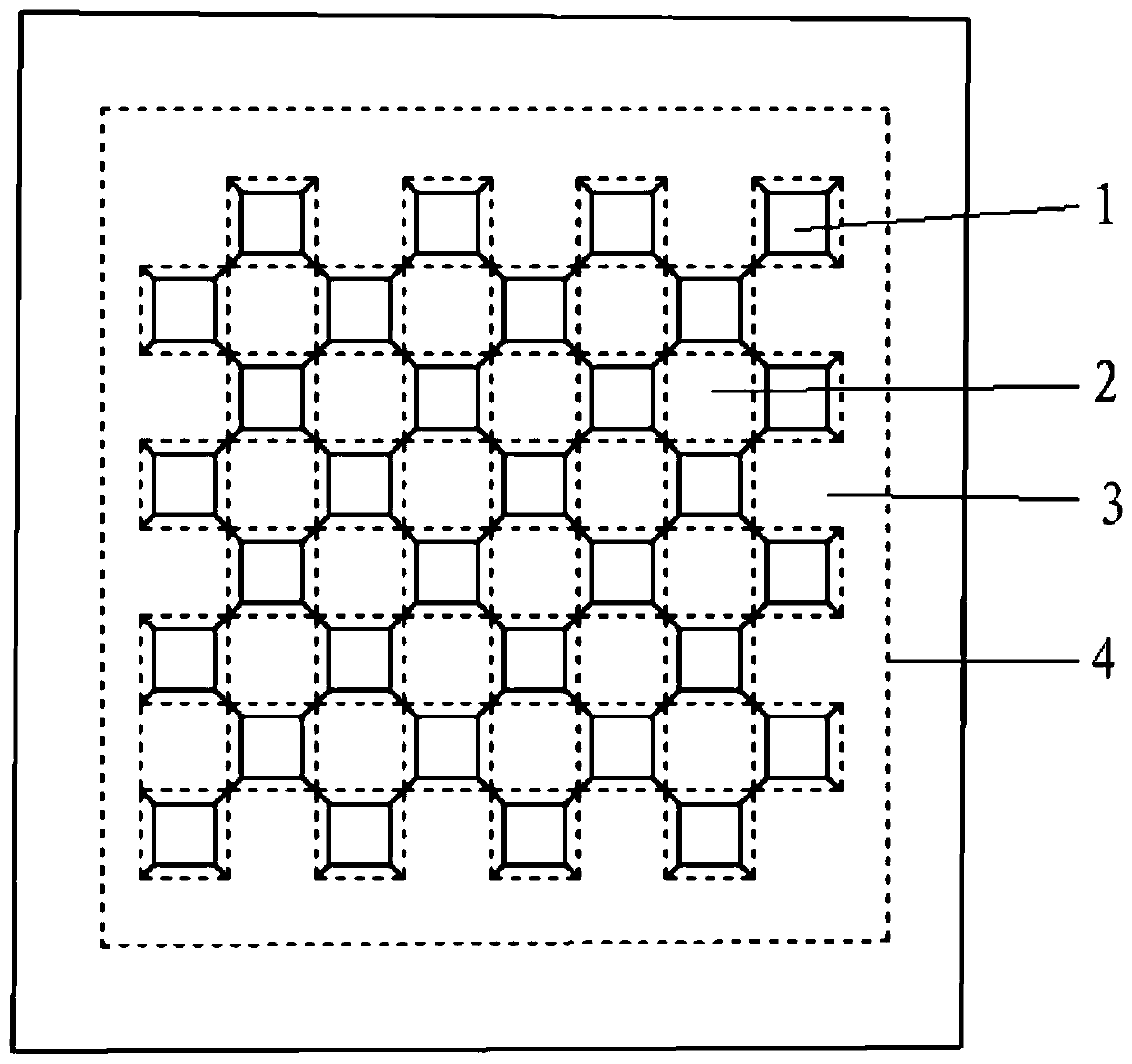

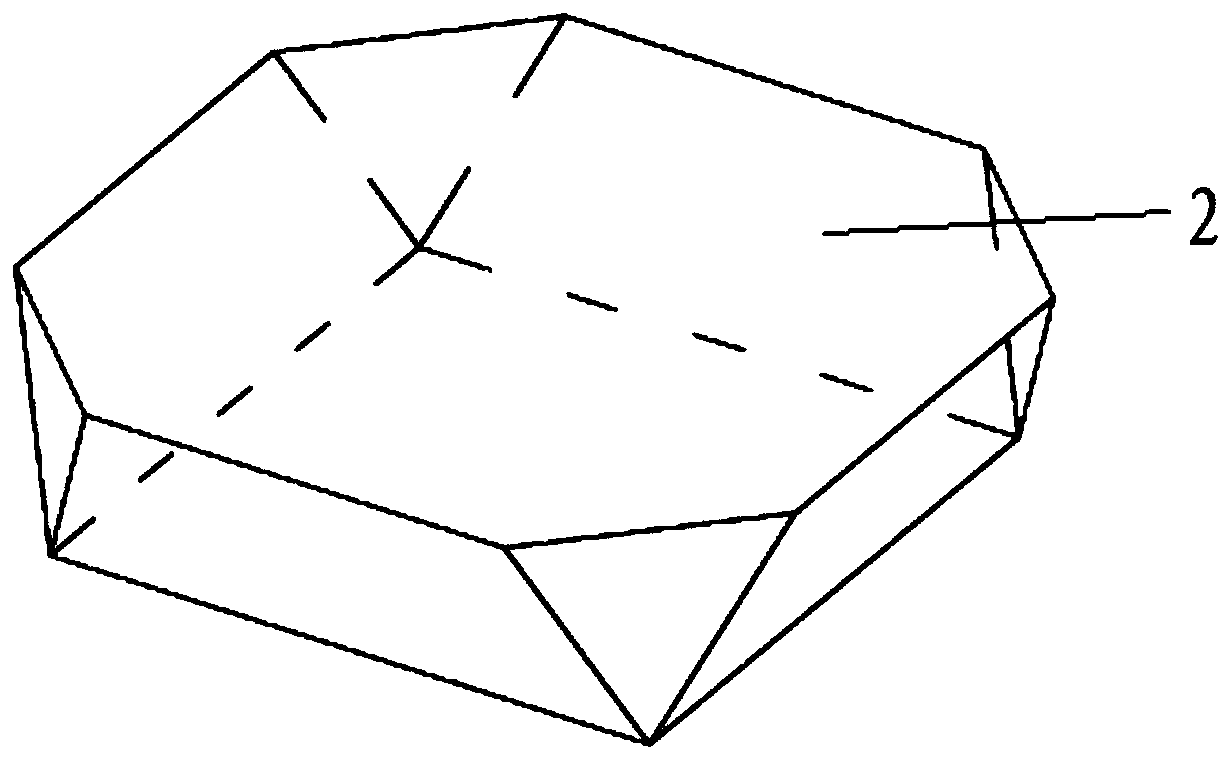

Embedded type flexible anti-piercing material and preparation method thereof

InactiveCN109737816AImprove flexibilityGood anti-stab performancePersonal protection gearCOMPONENT IITwo layer

The invention discloses an embedded type flexible anti-piercing material and a preparation method thereof. The embedded type flexible anti-piercing material comprises two layers of flexible base cloth, a component I and a component II, wherein the two layers flexible base cloth are compounded with each other, the bottom surface of the component I is fixed on the inner side of the lower-layer flexible base cloth, and the top surface of the component II is fixed on the inner side of the upper-layer flexible base cloth; the shape of the component I is a regular quadrangular frustum, the bottom surface of the component II is square, and the top surface of component II is octagonal, the side face where four edges are located is a trapezoid matched with the side face of the adjacent component I,and the side face where the other four edges are located is a triangle matched with the corresponding side face of the diagonal adjacent component II. The preparation method comprises the following steps of adhering the component I and the component II to the inner sides of the two layers of flexible base cloth according to a rule respectively, and drying; aligning the component I and the component II on the two layers of flexible base cloth and then compounding with each other to obtain the flexible anti-piercing material. The embedded type flexible anti-piercing material can be applied to various kinds of anti-piercing or protective articles, the soft and breathable performances of the anti-piercing material are greatly improved on the premise that the anti-piercing performance is guaranteed.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com