Composite material for bulletproof helmet and preparation method thereof

A technology for composite materials and bulletproof helmets, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve problems such as complex manufacturing methods of bulletproof helmets, achieve good industrialization prospects, good bulletproof performance, and comfort good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

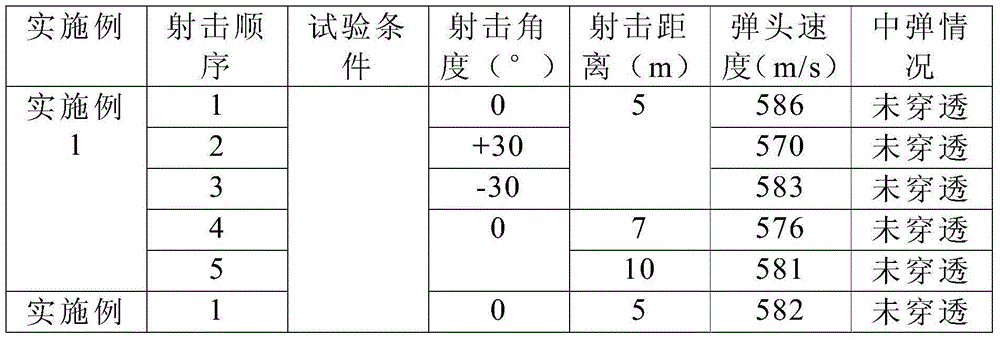

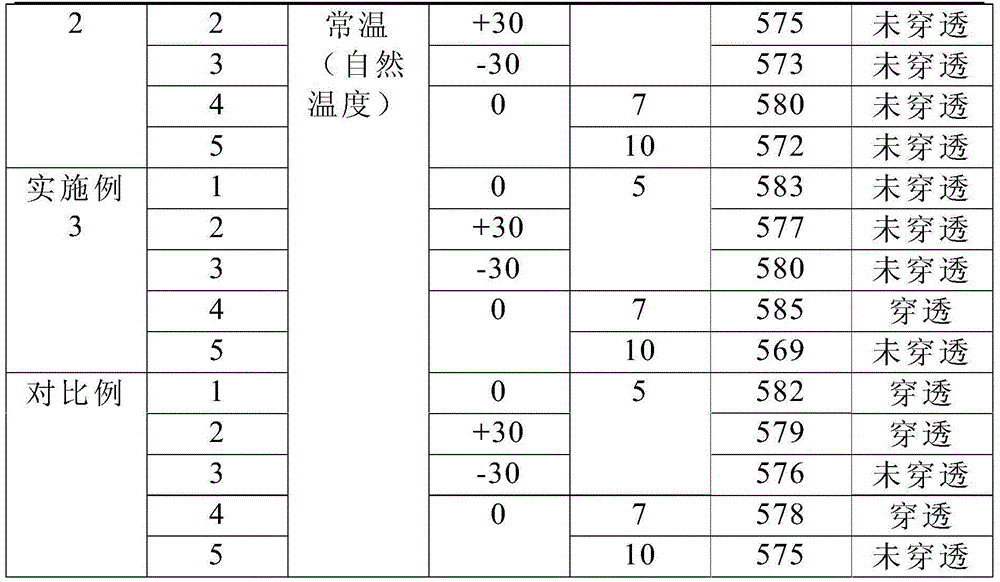

Embodiment 1

[0030]Add an appropriate amount of acetone to the PU prepolymer, stir evenly, and make a glue solution for use;

[0031] Fix the aramid fiber on the creel, and one end of the drawn fiber is fixed on the winding roller of the winding machine after passing through the tensioner and the spreader, and the winding machine is started for winding, and the glue is applied according to the design requirements. After reaching the specified width, Cut the prepared prepreg along the winding roller generatrix, and dry it in a ventilated place;

[0032] Cut the prepreg according to the specified specifications, perform orthogonal layup according to the method of 0° / 90° / 0°, and perform hot pressing on a pressure molding machine to obtain aramid non-weft fabric;

[0033] 20 layers of aramid non-weft fabrics are cut into aramid non-weft fabric layers according to the shape and size of the required helmet, wherein the cloth surface density in the aramid non-weft fabric layers is 150g / cm 2 ;

...

Embodiment 2

[0037] Add an appropriate amount of acetone to the PU prepolymer, stir evenly, and make a glue solution for use;

[0038] Fix the aramid fiber on the creel, and one end of the drawn fiber is fixed on the winding roller of the winding machine after passing through the tensioner and the spreader, and the winding machine is started for winding, and the glue is applied according to the design requirements. After reaching the specified width, Cut the prepared prepreg along the winding roller generatrix, and dry it in a ventilated place;

[0039] Cut the prepreg according to the specified specifications, perform orthogonal layup according to the method of 0° / 90° / 0°, and perform hot pressing on a pressure molding machine to obtain aramid non-weft fabric;

[0040] 18 layers of aramid non-weft fabrics are cut into aramid non-weft fabric layers according to the shape and size of the required helmet, wherein the cloth surface density in the aramid non-weft fabric layers is 140g / cm 2 ; ...

Embodiment 3

[0044] Add an appropriate amount of acetone to the PU prepolymer, stir evenly, and make a glue solution for use;

[0045] Fix the aramid fiber on the creel, and one end of the drawn fiber is fixed on the winding roller of the winding machine after passing through the tensioner and the spreader, and the winding machine is started for winding, and the glue is applied according to the design requirements. After reaching the specified width, Cut the prepared prepreg along the winding roller generatrix, and dry it in a ventilated place;

[0046] Cut the prepreg according to the specified specifications, perform orthogonal layup according to the method of 0° / 90° / 0°, and perform hot pressing on a pressure molding machine to obtain aramid non-weft fabric;

[0047] 22 layers of aramid non-weft fabrics are cut into aramid non-weft fabric layers according to the shape and size of the required helmet, wherein the cloth surface density in the aramid non-weft fabric layers is 170g / cm 2 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com