Aramid fiber bulletproof shield manufacturing method

A technology of bulletproof shields and aramid fibers, which is applied in chemical instruments and methods, defenses, textiles and papermaking, etc., and can solve problems such as high price, temperature resistance defects, and application field limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First, weigh 1000g of acrylate adhesive aqueous solution and 100g of polyurethane adhesive emulsion, wherein the solid content of acrylate adhesive aqueous solution is 50%, and the solid content of ethylene-vinyl acetate adhesive emulsion is 50%. After mixing evenly, weigh 110g of Sanya Ethylenediamine, fully mix the glue solution for later use.

[0019] The aramid fiber is wound in parallel on the winding machine, and then the fiber is immersed in the above glue solution, and the yarn is spread by a specific spinning equipment. The adhesive used in this example is the above-mentioned modified adhesive. After dipping, spread the glue evenly with a squeegee, and dry it under an electric resistance wire at 80°C. After it is completely dry, rotate the cloth sample at 90°C, The method is to carry out orthogonal compounding of the fiber filaments and the sample fiber filaments, and obtain two layers of interlaced fabric samples. The resulting product structure is correspond...

Embodiment 2

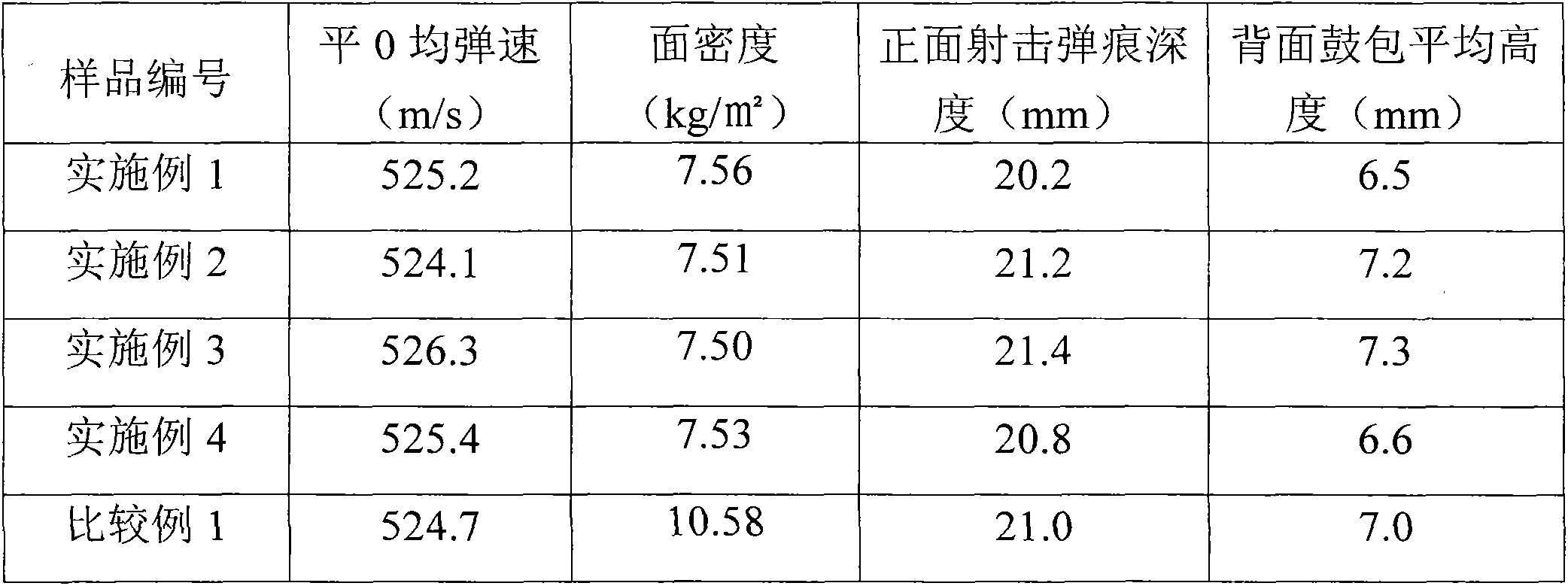

[0022] Change the polyurethane adhesive emulsion in Example 1 to 10g, and all the other conditions are the same as in Example 1. Adopt Type 54 7.62mm pistol, Type 51 7.62 pistol bullet (lead core), test by GA423-2003 "Bulletproof Shield", the results are shown in Table 1.

Embodiment 3

[0024] In Example 1, 11 g of triethylenediamine was used, and the rest of the conditions were the same as in Example 1. Adopt Type 54 7.62mm pistol, Type 51 7.62 pistol bullet (lead core), test by GA423-2003 "Bulletproof Shield", the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com