Steel plate for shield and preparation method thereof

A technology for steel plates and shields, which is applied in the field of steel plates for shields and its preparation, and can solve problems such as inapplicability to the production of shields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

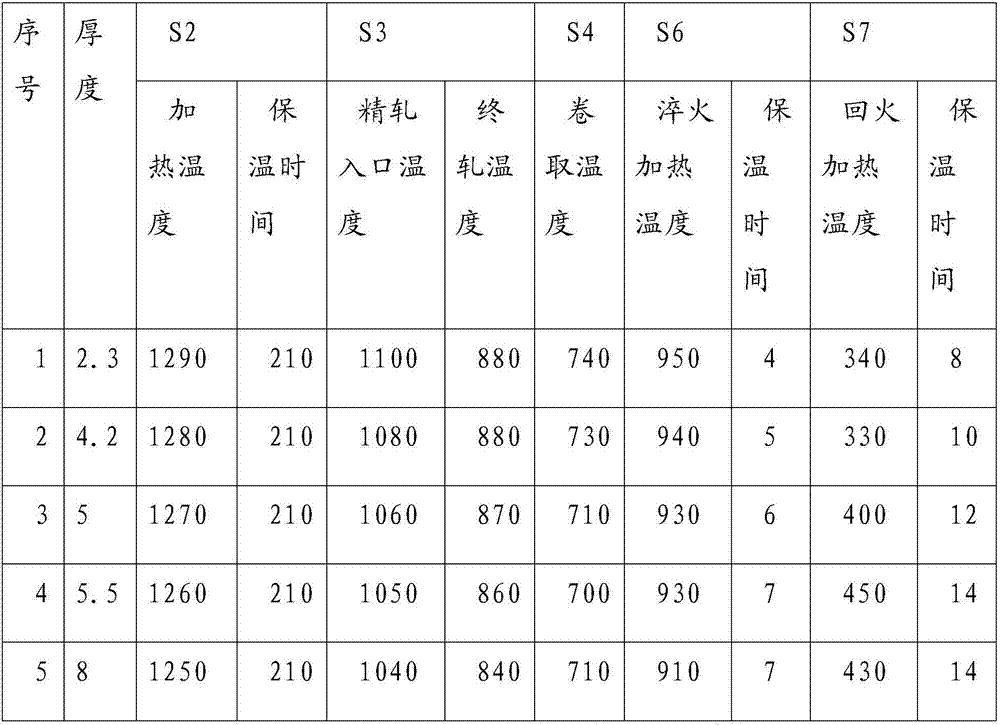

[0030] Another aspect of the present invention provides a preparation method for producing the above-mentioned shield steel plate, comprising the following steps:

[0031] Step 1, the molten iron is smelted in a converter or an electric furnace, LF refined or RH refined to obtain molten steel with the composition described in claim 1, and then continuously cast to obtain a slab.

[0032] Step 2, reheating the billet in a heating furnace, and then rough rolling and finish rolling to obtain a hot-rolled plate.

[0033] In step 3, the hot-rolled sheet is subjected to laminar flow cooling, and then rolled into a coil to obtain a steel coil.

[0034] In step 4, the steel coil is slowly cooled, and then subjected to continuous heat treatment to obtain a finished product.

[0035] Among them, the specific process parameters are controlled as follows:

[0036] The slab is heated to 1220-1300°C in the heating furnace, and the heating time is more than 210 minutes. The purpose of usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com