Application of carbon nanotube aggregates to preparation of bulletproof composite and preparation method of bulletproof composite

A technology of bulletproof composite materials and carbon nanotubes, which is applied in the direction of offensive equipment, protective equipment, personnel protection equipment, etc., can solve the problems of non-uniform weft cloth structure, poor heat resistance, large creep, etc., and achieve excellent protection effect, Excellent heat resistance and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Another aspect of the embodiments of the present invention provides a method for preparing a bulletproof composite material comprising:

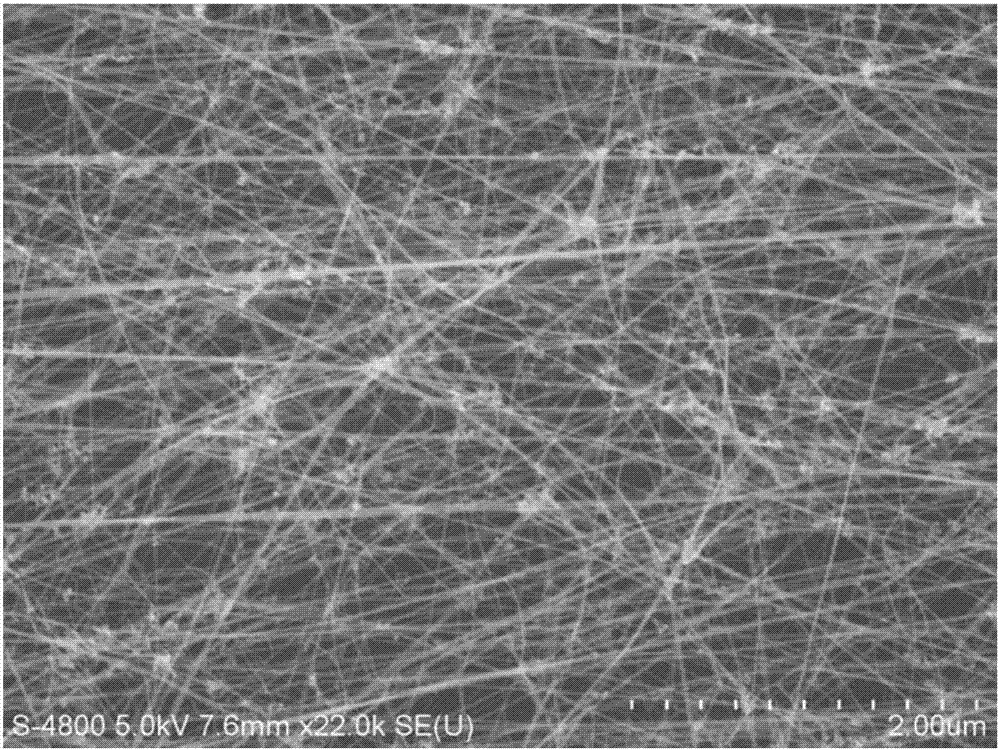

[0082] A plurality of carbon nanotube continuums are continuously aggregated on a continuous surface and densified to form a plurality of oriented basic units, and the multiple basic units are densely arranged to form a carbon with a macroscopic two-dimensional planar structure. Nanotube aggregates, wherein the carbon nanotube continuum is formed by disorderly interweaving of multiple carbon nanotubes, and presents a closed, semi-closed or open two-dimensional or three-dimensional spatial structure before densification treatment;

[0083] The carbon nanotube aggregate is fixedly attached to the surface of the fabric to form the bulletproof composite material.

[0084] Preferably, referring to the foregoing, the carbon nanotube continuum is prepared by a floating catalytic cracking method.

[0085] Further, the continuous surface is a...

Embodiment 1

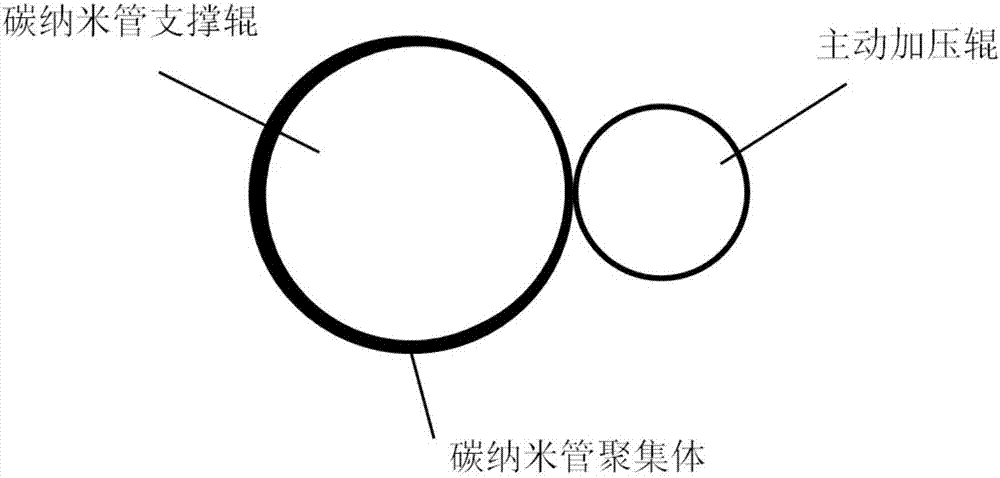

[0105] 1) Relying on the van der Waals force between carbon nanotubes, the tubular hollow carbon nanotube continuum grown from a high-temperature furnace (refer to "Science", 2004, 304 issue, p276), under the buoyancy of the air, It is continuously wound on a cylindrical horizontal drum. While the drum is rotating, it can reciprocate along the axial direction. The moving distance is the length of the drum. After a certain period of continuous collection, ethanol is used on the surface of the obtained continuous carbon nanotube aggregates Spray while applying pressure using cylindrical steel rollers (see figure 1 ), the pressure is about 4MPa. After the solvent evaporates at room temperature, remove it from the support round roller to form a self-supporting nano-carbon film, and then press it with a press to further increase the density of the film. The pressure used is 15 MPa, the temperature is about 90 ° C, and the time is about 2 hours. , the final obtained carbon nanotube...

Embodiment 2

[0110] 1) With reference to the carbon nanotube preparation process of Example 1, relying on the van der Waals force between the carbon nanotubes, the tubular hollow carbon nanotube continuum grown from the high-temperature furnace (referred to in the comparatively typical case mentioned above) The preparation process of the carbon nanotube continuum), under the buoyancy of the air, is continuously wound on the cylindrical horizontal drum. While the drum is rotating, it can reciprocate along the axial direction. The moving distance is the length of the drum. The cumulative After collecting continuously for a certain period of time, use a graphene alcohol solution (concentration of about 0.1wt% to 5wt%) on the surface of the obtained continuous carbon nanotube aggregate. The alcohol solvent can be propanol, ethanol, ethylene glycol, etc., or mixed solvent of alcohol and water) spraying, and at the same time, using cylindrical steel rollers for pressure (see figure 1 ), the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com