Multi-layer multi-material flexible stab-resistant fabric and its weaving method

A technology of fabrics and raw materials, applied in the direction of multi-strand fabrics, fabrics, textiles, and papermaking, can solve the problems of insufficient comfort of stab-resistant fabrics, and achieve the effects of promoting diversified development, good economic and social benefits, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

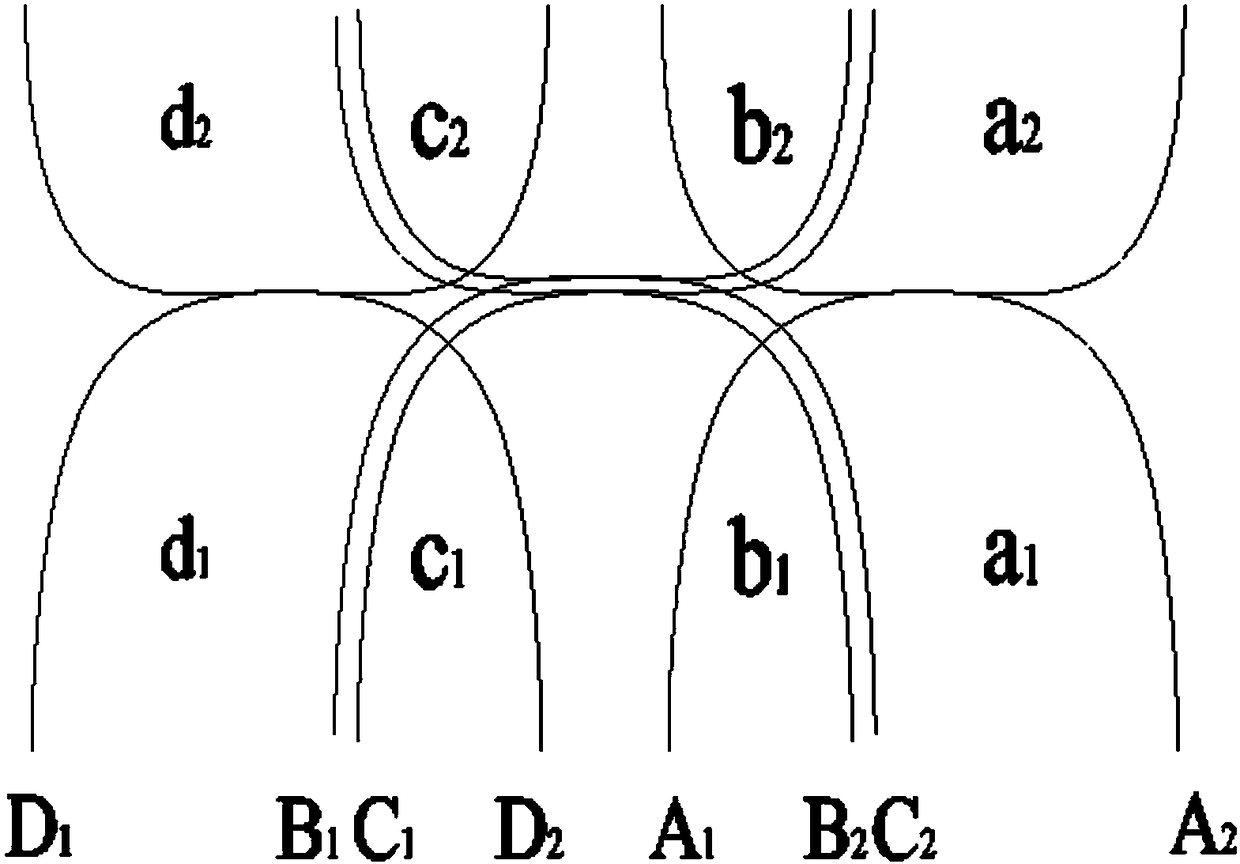

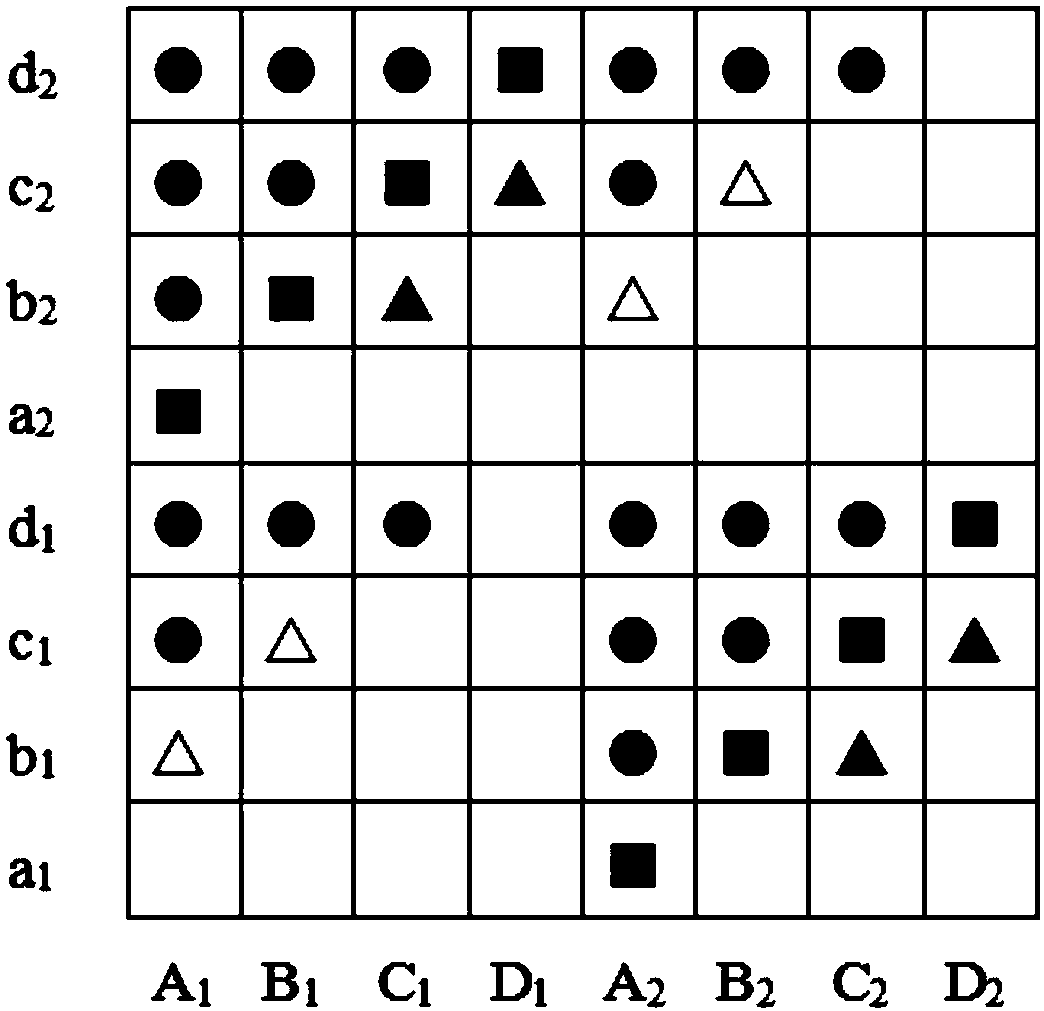

[0025] A multi-layer multi-material flexible stab-resistant fabric, with four layers in total, in which each layer of fabric is made of plain weave, the arrangement ratio of warp and weft yarns is 1:1:1:1, and the connection mode between each layer is joint bonding. And the binding organization is plain weave. Specifically, the first layer and the second layer choose the top connection method, and the third layer and the fourth layer choose the bottom connection method, such as figure 1 As shown in the figure, A 1 and A 2 Indicates the first layer of warp, B 1 and B 2 Indicates the second layer of warp, C 1 and C 2 Indicates the third layer of warp, D 1 and D 2 Indicates the fourth layer of warp; a 1 and a 2 Indicates the first layer of weft yarn, b 1 and b 2 Indicates the second layer of weft yarn, c 1 and c 2 Indicates the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com