Impact-resistant composite structure

A composite structure, impact-resistant technology, applied in the direction of layered products, etc., can solve the problems of unfavorable spinning and weaving, small friction coefficient, low fiber cohesion, etc., and achieve the effects of reducing manufacturing costs, improving stab resistance, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement them after studying this specification. It is worth noting that, in order to clearly demonstrate the main features of the present invention, each figure only schematically shows the relative relationship or operation mode between the main components, and is not drawn according to the actual size, so the thickness, size and shape of the main components in the figure , arrangement, configuration, etc. are for reference only, and are not intended to limit the scope of the present invention.

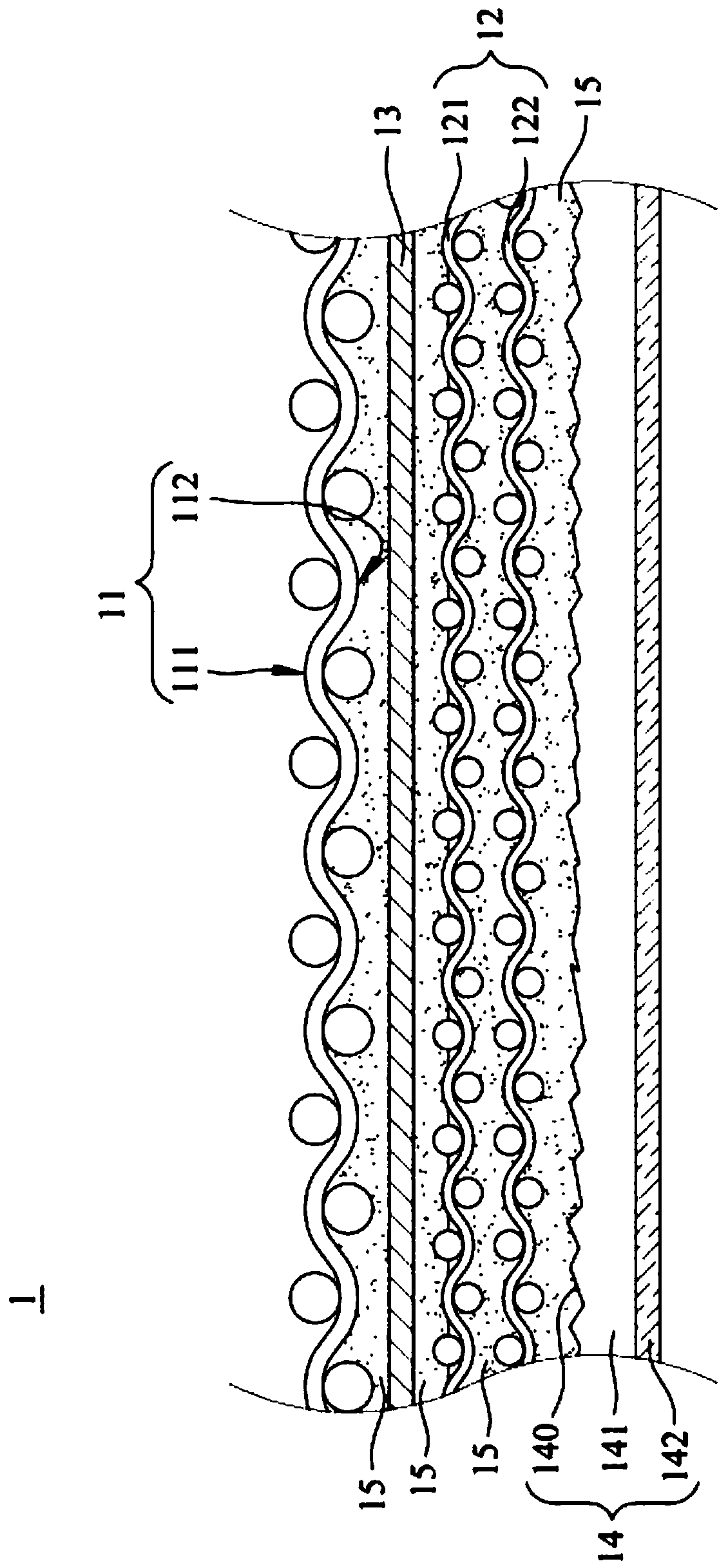

[0018] figure 1 It is a schematic cross-sectional view of the impact-resistant composite structure of the present invention. Such as figure 1 As shown, the impact-resistant composite structure 1 includes: a first fabric 11 , a second fabric layer 12 , a non-woven fabric 13 , a fiber resin layer 14 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com