Penetration inhibition type stab-resistant cloth capable of preventing scratching and stabbing and process thereof

A stab-proof and high-tech technology, applied in the field of clothing production, can solve the problems of complex production process, low production efficiency and low stab-proof performance of stab-proof cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

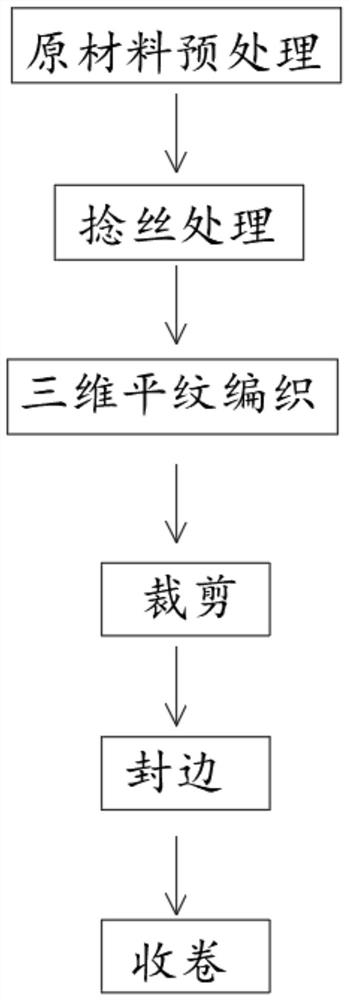

[0031] Such as Figure 1-3 As shown, the penetration-inhibiting stab-resistant cloth process for preventing scratches includes the following steps:

[0032] Sp1: Raw material pretreatment, the raw materials are ultra-high molecular weight polyethylene fiber filaments and high-strength viscose fiber filaments, and the ultra-high molecular weight polyethylene fiber filaments and high-strength viscose fiber filaments are cut to the same length;

[0033] Sp2: Twisting treatment, twisting ultra-high molecular weight polyethylene fiber filaments and high-strength viscose fiber filaments, using three filaments to twist into one, three twisted into one strand, and the twist is 300 twists / m;

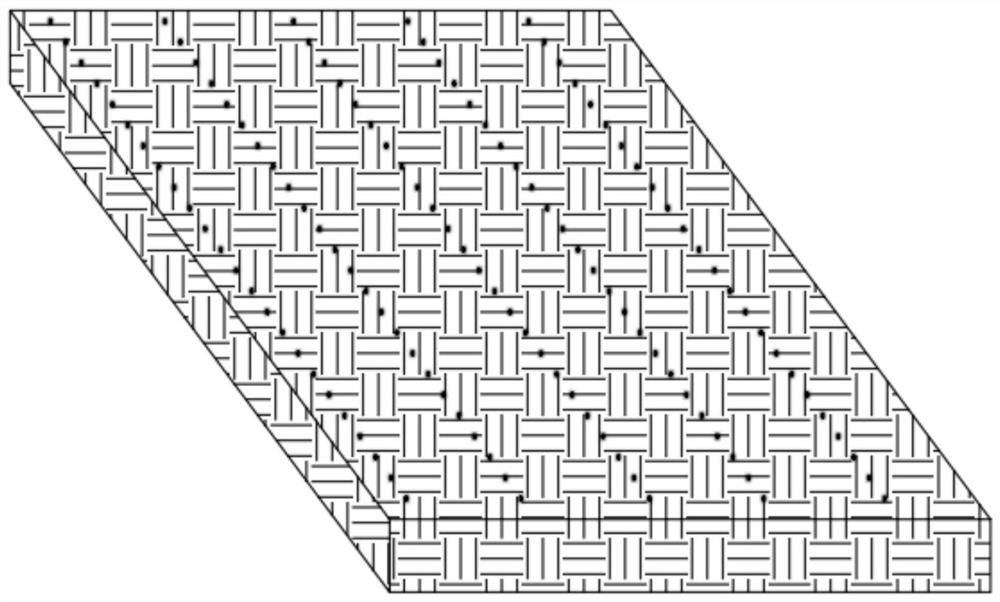

[0034] Sp3: Three-dimensional plain weave, three-dimensional plain weave uses ultra-high molecular weight polyethylene fiber filament strands to carry out radial, weft and Z-direction simultaneous weaving and forming, three-dimensional plain weave has 24 vertical layers, and the first eight layer...

Embodiment 2

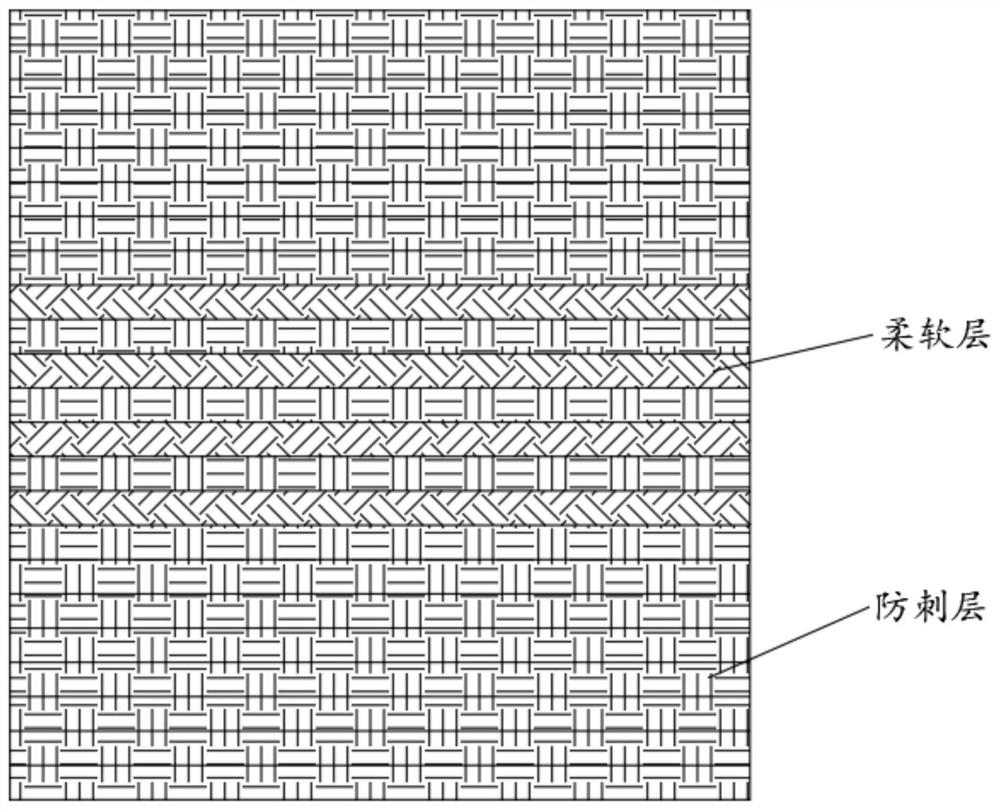

[0041] Penetration-inhibiting stab-resistant fabric for preventing scratches, including the main body of the stab-resistant fabric. The main body of the stab-resistant fabric includes a stab-resistant layer, a connecting layer and a soft layer. The stab-resistant layer is made of ultra-high molecular weight polyethylene fiber filament strands. Horizontal direction plain weave Forming, the soft layer is formed by high-strength viscose fiber strands in the horizontal direction plain weave, the connecting layer is formed by the vertical direction plain weave of ultra-high molecular weight polyethylene fiber filament strands, and the connection layer is woven through the anti-stab layer and the soft layer in turn Weaving, the soft layer and the anti-stab layer are staggered in 1:1, and there are 8 layers in total. The top and bottom surfaces of the soft layer and the anti-stab layer are symmetrically distributed, and there are 8 layers of anti-stab layers. The ultra-high molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com