Killing human-shaped target for training and production process of killing human-shaped target

A production process and curing molding technology, applied in the field of assassination-type targets, can solve the problems of low service life, low repeated utilization rate, poor stab-proof effect, etc., and achieve the effect of prolonging the service life and improving the stab-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

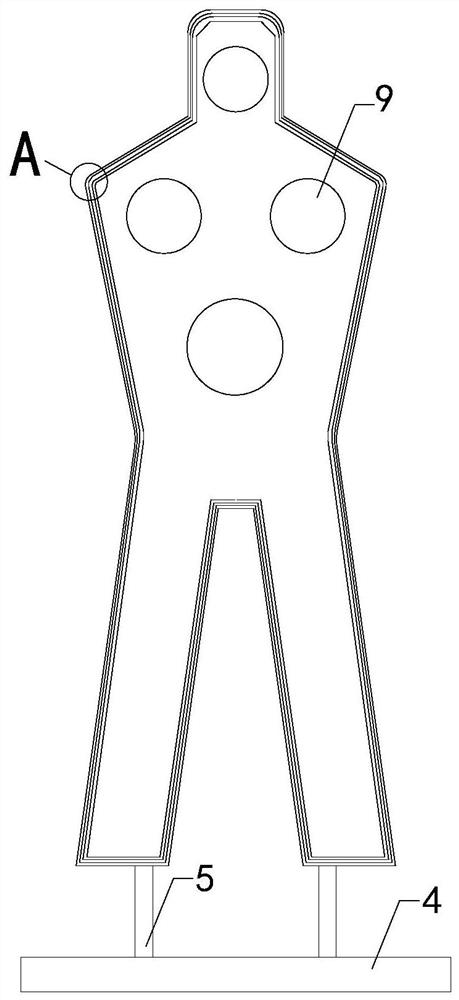

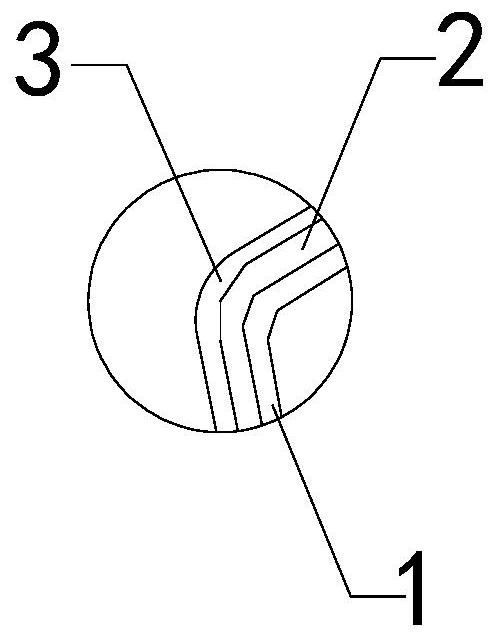

[0035] See Figure 1-3 One training of the present invention has a hike-type target including a nonwoven articulated man-made mold including a nonwoven fabric structure 1, and a glue is coated with a surface of the non-woven layer structure 1. Layer 2, the rubber layer 2 infiltrates to the inside of the nonwoven fabric structure 1, and the surface of the glue layer 2 is provided with a composite silicon gel plate 3.

[0036] The moral ratio of the nonwoven fabric structure 1 and the colloid layer 2 is 1: 1.

[0037] See figure 1 The composite silica gel 3 has a thickness of 3 mm, and the non-woven artery is placed on the face, the chest and the abdomen position, and the reinforcing layer uses a non-woven fabric prepared by ultra-high molecular weight polyethylene fiber wire. The company's application number is CN202010656186.1 Neutral non-spinning.

[0038] In this application, the stimuli performance and strength of the assassinarian target is further improved by providing a reinf...

Embodiment 2

[0056] Unlike Example 1, the mass ratio of the nonwoven fabric layer structure 1 and the rubber layer 2 is 1: 1.2;

[0057] The composite silica gel plate 3 has a thickness of 5 mm;

[0058] See Figure 5 The reinforcing layer is designed to be: excavated the face position, chest position, and abdominal position of the non-woven human model, and the inside of the non-woven human model is provided with a support rod 10 connected to the base, and the top of the support rod extends. On the hole position, the support steel piece 11 is provided at the end of the support rod, and the reinforcing layer is provided on the front surface of the supporting steel sheet, and the reinforcing layer is just located at a hole.

[0059] In this application, by providing the reinforcing layer on the support rod connected to the base, the support effect of the reinforcing layer is further improved, and the puncture performance is improved.

[0060] The nonwoven fabric structure 1 selects a nonwoven ne...

Embodiment 3

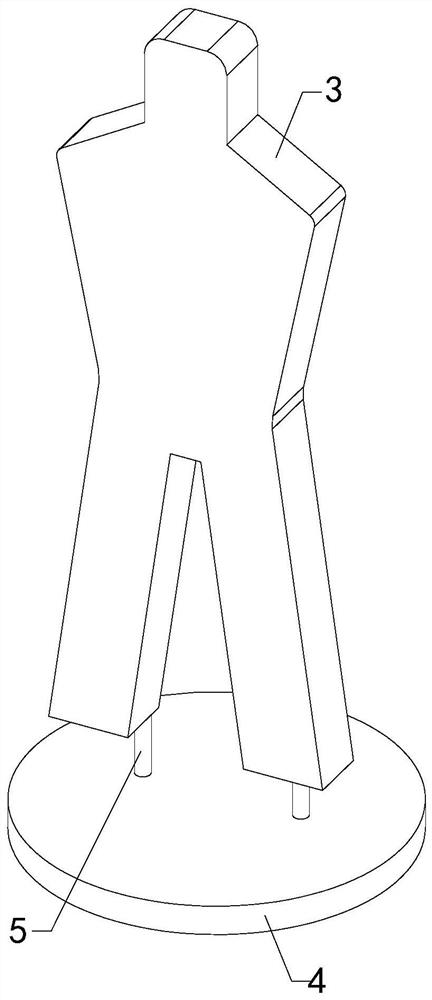

[0063] Clearance reading Figure 4 The rising frame 5 includes two sets of struts 7 and two sets of sliding jaws 8, and the two sets of sliding sleeves 8 are fixedly coupled to both leg positions of the wood back plate 6, and the bottom ends of the two sets of pillars 7 Attached to the base 4, the top of the two sets of pillars passes through the two sets of slide, and the adjustment bolts for fixing the slip post are provided on the two sets of sliders.

[0064] In use, by using non-woven fabric structural 1 and rubber layer 2, the anti-woven effect is improved, and the puncture ability is between 10-24 Joules; The surface of the model is provided with a composite silica gel plate 3. After a period of use, the composite silica gel plate 3 can be removed, and then the nonwoven articles are applied, cured, and then the composite silicone plate 3 posted in the non-woven fabric. Human-type die surfaces can achieve repeated utilization and extend service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com