Thorn-proof composite material and preparation method thereof

A composite material and stab-proof technology, applied in protective equipment, chemical instruments and methods, offensive equipment, etc., can solve the problems of higher puncture resistance performance requirements of stab-proof materials, and the inability of stab-proof clothing to meet new standards, and achieve excellent Stab resistance, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The anti-stab composite material of the present invention can be prepared by conventional preparation methods in the field; the preparation method of the present invention can also be used, which includes the following steps: preparing raw materials—heating and dissolving—adding particles—gluing— Drying at room temperature - thermocompression molding. Specifically:

[0027] (1), prepare raw materials

[0028] Raw materials include fiber reinforcements, solid colloidal particles, solvents, and nanoscale oxide particles. Firstly, the fiber reinforcement is pretreated to make the cloth dense.

[0029] (2), heating and dissolving

[0030] Add solid colloidal particles with a weight percentage of 10%-30% to the solvent, and heat up until the colloidal particles are completely dissolved. The solvent is selected from one or more of methanol, ethanol, acetone, methyl ethyl ketone, cyclohexanone, dichloromethane, ethyl acetate, and butyl acetate.

[0031] (3), add particles ...

Embodiment 1

[0043] Embodiment 1 Coating non-woven fabric adds the preparation of buffer layer structure anti-stab composite material

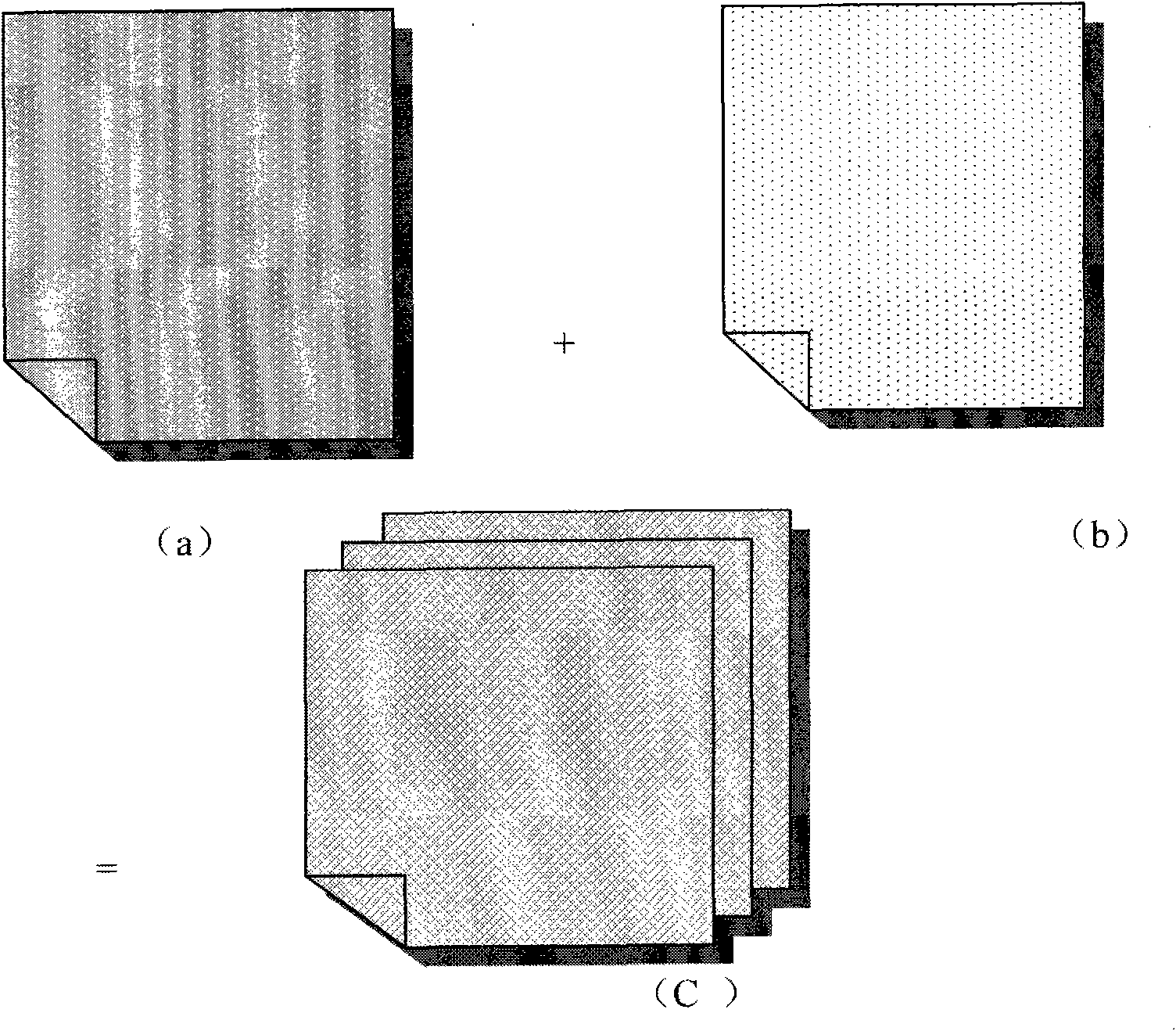

[0044] The anti-stab material is composed of a sheet-shaped single-layer composite material with microporosity and a cushioning material in proportion. Comfortable cushioning material.

[0045] The non-woven reinforcement is produced by Beijing Tongyizhong Special Fiber Technology Development Co., Ltd. The raw material used is ultra-high molecular weight polyethylene staple fiber with a length of 50mm. Ingredient amount is 200g / m 2 The surface density of the base cloth with microporous structure, the thickness of the base cloth in loose state is 1-2.5mm, and the porosity is 60%; the thickness of the non-woven fabric after compaction is 0.15-0.3mm, and the porosity is 25%.

[0046] Preparation of the resin system: add 10% by weight solid polyurethane micelle to ethanol, heat up until the micelle is completely dissolved, add 5% silicon oxide particles in p...

Embodiment 2

[0048] The preparation of embodiment 2 soft comfortable stab-proof composite material

[0049] The anti-stab material is composed of a sheet-shaped single-layer composite material with microporosity and a cushioning material in proportion. Comfortable cushioning material.

[0050] The woven fabric reinforcement is woven from ultra-high molecular weight polyethylene fiber filaments produced by Beijing Tongyizhong Special Fiber Technology Development Co., Ltd. After optimization, the yarn linear density is 400D, the mechanical strength is 33cN / dtex, and the specification of the woven fabric is warp ( Weft) density 150 / 10cm, fabric surface density 100g / m 2 , fabric thickness 0.18mm.

[0051] Preparation of the resin system: add 30% by weight solid polyacrylate micelle to acetone, heat up until the micelle is completely dissolved, add 15% zinc oxide particles in proportion to the weight of the dissolved solution, and stir evenly. Glue is applied by dipping and compounding, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com