Soft prick-preventing layer material and its prepn and use

A layered material and stab-proof technology, applied in the field of multi-layer composite materials, can solve the problems of poor comfort, high economic cost, complex manufacturing process, etc., and achieve the effect of reducing economic cost, good stab-proof performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

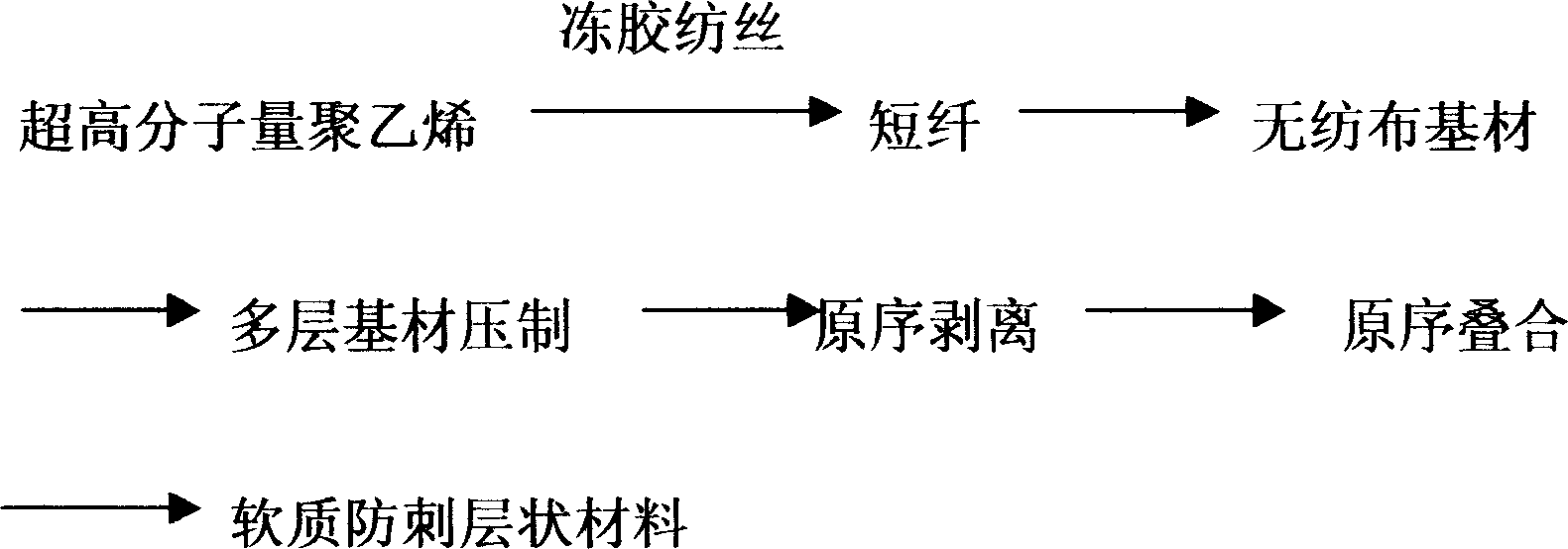

Method used

Image

Examples

Embodiment 1

[0046] The soft stab-resistant layered material described in this embodiment is made of 24 layers of non-woven fabrics, and the layers can slide freely.

[0047] The preparation process is as follows: the linear polyethylene powder with a viscosity-average molecular weight of 3.5 million units (the ratio of weight-average molecular weight to number-average molecular weight is 4) is used as raw material, and the tensile breaking strength is 25g / d, and the modulus It is a high-strength polyethylene fiber of 1000g / d, a monofilament fineness of 3d, and an average length of 100mm, and uses polyphenylene sulfide type for anti-static surface treatment.

[0048] Then open and comb, use acupuncture equipment, the acupuncture density is 250 needles / cm 2 , the surface density is 200g / m 2 24 layers of non-woven fabric base material, then superimposed with 24 layers, pressurized at 12MPa for 40 minutes, peeled off layer by layer under normal temperature and pressure, stacked in the origin...

Embodiment 2

[0059] The soft anti-stab layered material described in this embodiment is formed by stacking five layers of non-woven fabrics, and the layers can slide freely.

[0060] The preparation process is as follows: the linear polyethylene powder with a viscosity-average molecular weight of 5 million units is used as raw material, and the tensile breaking strength is 28g / d, the modulus is 900g / d, the single filament fineness is 5d, and the average High-strength polyethylene fibers with a length of 110mm and anti-static surface treatment with PVC type.

[0061] Then open and comb, use acupuncture equipment, the acupuncture density is 300 needles / cm 2 , the surface density is 220g / m 2 The non-woven fabric base material is superimposed with 5 layers, pressurized at 10MPa for 30 minutes, peeled off layer by layer at normal temperature and pressure, stacked in the original order, and sprayed with paraffin oil between layers to make a stab-resistant surface with a density of 5.6kg / m 2 Th...

Embodiment 3

[0063] The soft anti-stab layered material described in this embodiment is formed by stacking 30 layers of non-woven fabrics, and the layers can slide freely.

[0064] The preparation process is as follows: the linear polyethylene powder with a viscosity-average molecular weight of 4 million units is used as raw material, and the tensile breaking strength is 22g / d, the modulus is 900g / d, the single filament fineness is 3d, and the average High-strength polyethylene fibers with a length of 120mm and anti-static surface treatment with polyacetylene type.

[0065] Then open and comb, use acupuncture equipment, the acupuncture density is 150 needles / cm 2 , the surface density is 180g / m 2 Then use 30 layers of non-woven fabric substrates, then stack them with 30 layers, pressurize at 12MPa for 80 minutes, peel them off layer by layer at normal temperature and pressure, stack them in the original order, and spray paraffin oil between layers to make a puncture-resistant surface with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com