Flexible stab-resistant material and preparation method thereof

A flexible, high-performance technology, applied in the field of flexible anti-stab materials and its preparation, can solve the problems of shear thickening fluid flow, affect the protective performance, and the protective body is not easy to maintain, etc., to achieve short molding process and high protective performance Enhanced, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

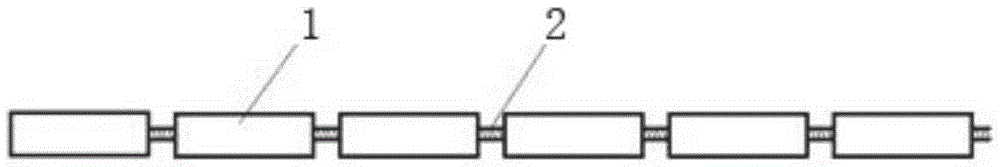

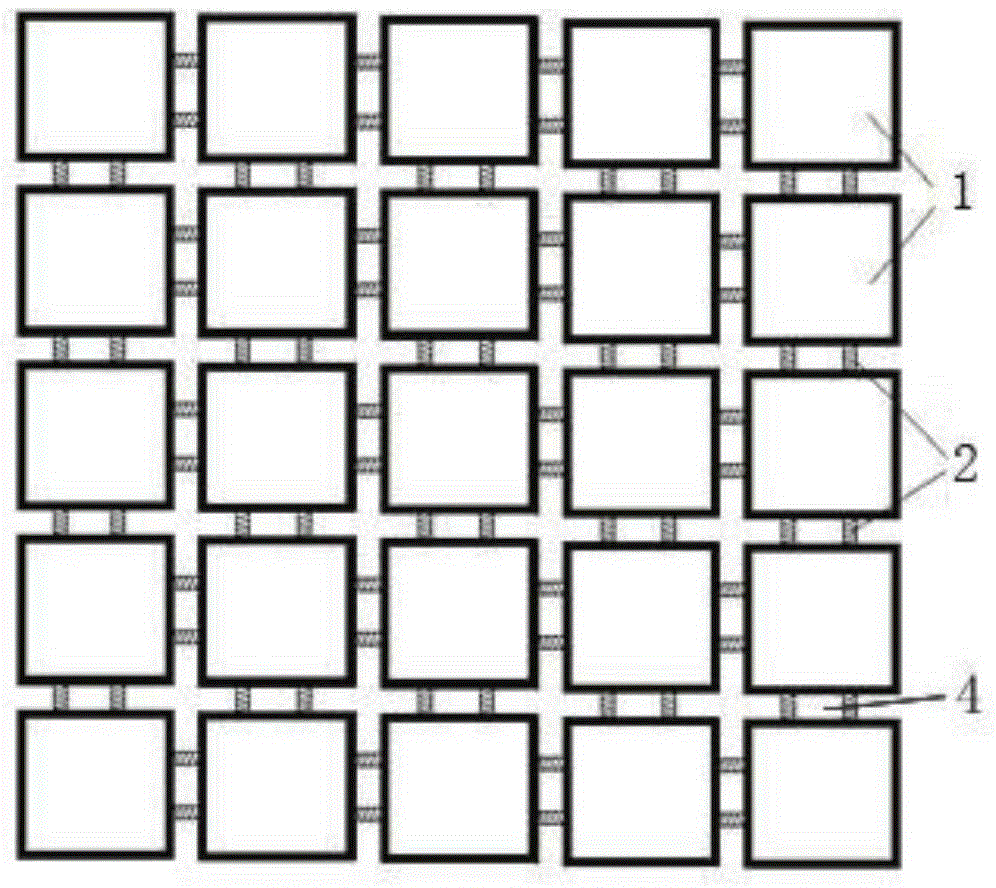

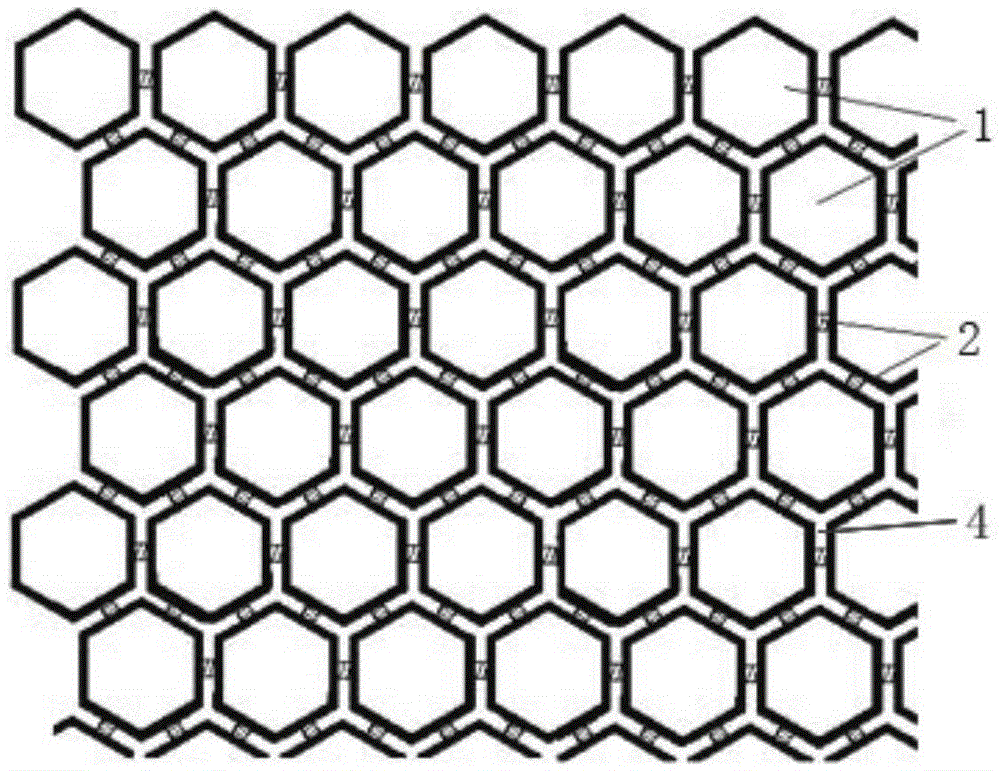

[0038] The protective small module material of the flexible stab-resistant material is made of carbon fiber staple fiber and nylon 66 composite material, the mass fraction ratio of carbon fiber short fiber and nylon 66 polymer material is 1:3, and the small protective module is made into a square with a side length of 8mm. The thickness is 1.5mm, the material connecting the small modules is aramid filament, the thickness is 1500D, and the gap between the small modules is 0.4mm.

[0039] The preparation method of the flexible anti-stab material is as follows: the injection temperature is 220 degrees, the pressure is 1.5 MPa, the injection time into the mold is 90 seconds, the holding time is 30 seconds, and the area of the protective material is 0.3m 2 The shape of the anti-stab vest, the three layers of the protective material injection molded are staggered and overlapped to form a protective layer. The total mass of the anti-stab layer of the anti-stab clothing is 1.8kg, whi...

Embodiment 2

[0041] The protective small module material of the flexible stab-resistant material is made of aramid fiber staple fiber and nylon 66 composite material, the mass fraction ratio of aramid fiber staple fiber and nylon material is 1:4, and the small protective module is made into a square with a side length of 4mm. The thickness is 1.2mm, the material connecting the small modules is aramid filament, the thickness is 400D, and the gap between the small modules is 0.3mm.

[0042] The preparation method of the flexible anti-stab material is as follows: the injection temperature is 220 degrees, the pressure is 1.5MPa, the injection time into the mold is 90 seconds, the holding time is 30 seconds, and the area of the protective material is 0.5m 2 The shape of the anti-slash vest, the number of protective materials injected from this is 1 protective layer, and the total mass of the protective layer of the anti-slash clothing is 1kg, which can effectively protect against cuts and cuts...

Embodiment 3

[0044] The protective small module material of the flexible stab-resistant material is made of aramid fiber staple fiber and polycarbonate reinforced composite material, the mass fraction ratio of aramid staple fiber and polycarbonate material is 1:4, and the side length of the protective small module is 4mm square with a thickness of 1.5mm. The material connecting the small modules is aramid filament with a thickness of 800D, and the gap between the small modules is 0.3mm.

[0045] The preparation method of the flexible anti-stab material is as follows: the injection temperature is 260 degrees, the pressure is 1.5MPa, the injection time into the mold is 90 seconds, the holding time is 30 seconds, and the area of the protective material is 0.3m 2 The shape of the anti-stab vest, the number of protective materials injection molded from this is 3 layers of protective layers, and the total mass of the protective layer of the anti-stab clothing is 1.7kg, which can effectively pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com