Z-shaped resin molding flexible puncture-proof fabric and preparation method thereof

A technology of resin molding and fabrics, applied in textiles, papermaking, fiber processing, etc., can solve the problems of no anti-stab effect, failure of anti-stab clothing, puncture of knives into gaps, etc., to achieve excellent anti-stab performance, low price, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

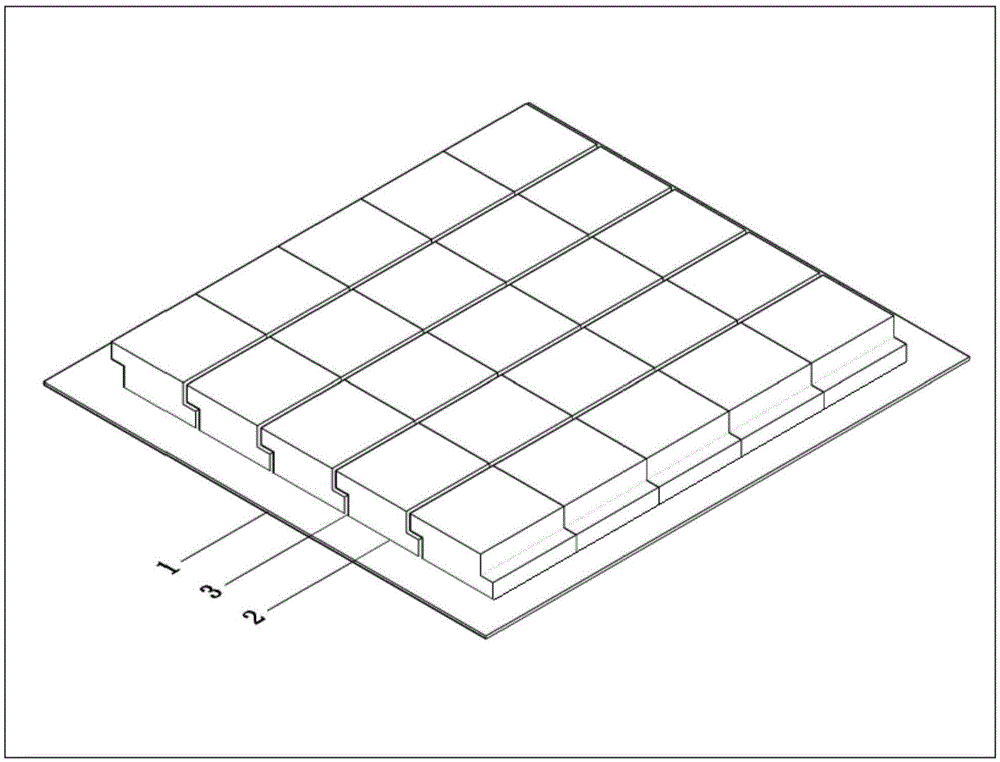

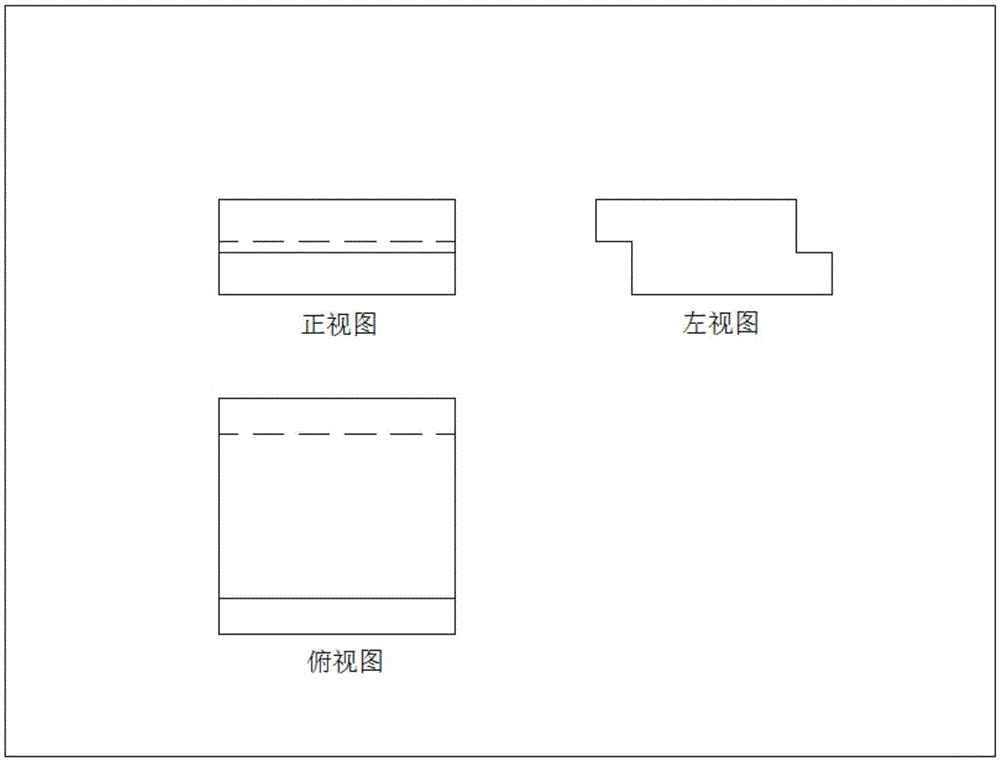

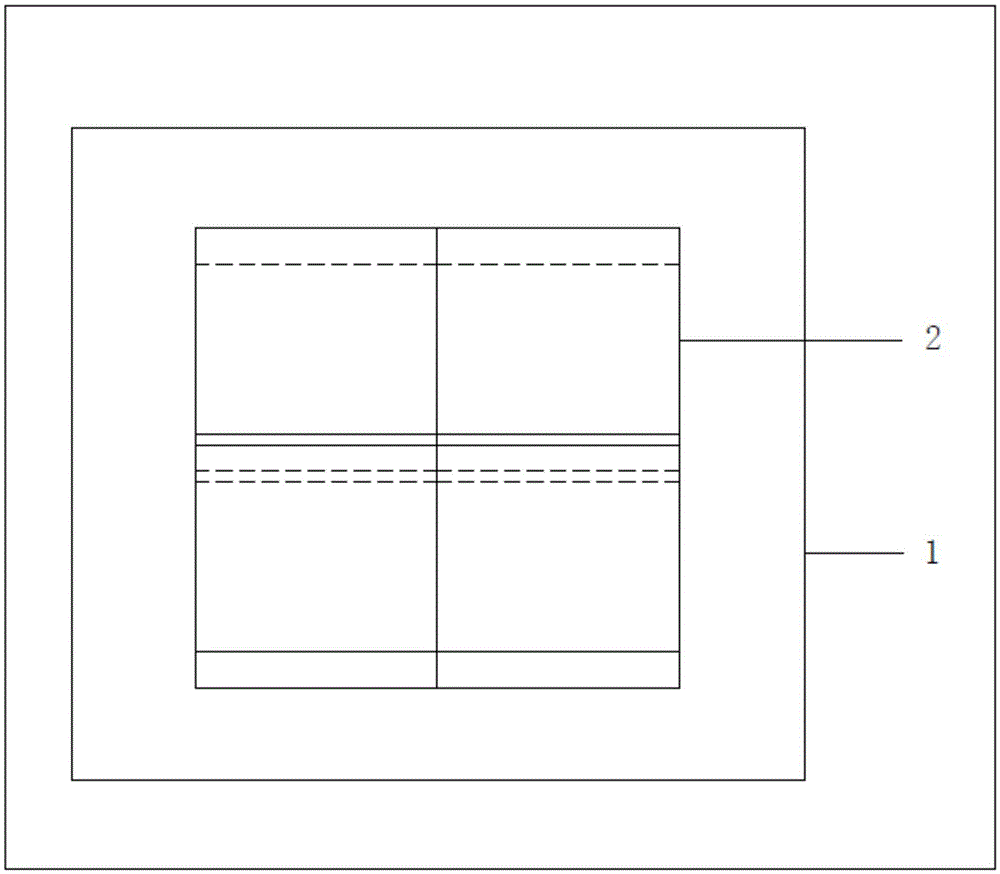

Embodiment 1

[0037] In this embodiment, the Z-shaped resin-molded flexible anti-stab fabric adopts polyester plain weave fabric as the base fabric, and the surface density is 200g / m 2, the warp and weft density is 304×316 (root / 10cm). The raw material of the cured resin printed by the 3D printer is polycarbonate wire. The preparation process of this stab-resistant fabric is as follows: a, draw the three-dimensional figure of the Z-shaped resin cured product on the UG drawing software, the top view of the Z-shaped resin cured product is a square with a side length of 20mm, and the maximum thickness of the cured product is 6mm, The minimum thickness is 2.5mm, import the picture into the 3D printer software, and the 3D printer will print out the polycarbonate cured product; b, evenly sprinkle hot melt adhesive powder on the garment fabric, and arrange the Z-shaped resin cured product neatly on the garment fabric , wherein the cured product is closely arranged without gaps between the columns...

Embodiment 2

[0041] In this embodiment, the Z-shaped resin-molded flexible anti-stab fabric adopts polyester plain weave fabric as the base fabric, and the surface density is 200g / m 2 , the warp and weft density is 304×316 (root / 10cm). The raw material of the Z-shaped resin cured product formed by injection molding technology is polycarbonate particles. The preparation process of the anti-stab fabric is as follows: a, Utilize injection molding technology to make a Z-shaped polycarbonate cured product, the top view of the Z-shaped resin cured product is a square with a side length of 20mm, the maximum thickness of the cured product is 6mm, and the minimum thickness is 2.5mm; b, evenly sprinkle hot-melt adhesive powder on the garment fabric, and arrange the Z-shaped resin cured products neatly on the garment fabric, where the cured products are closely arranged without gaps between columns, and the cured products are arranged between rows. There is a gap of 1 mm and a height difference of 1...

Embodiment 3

[0045] This Z-shaped resin-molded flexible anti-stab fabric uses polyester plain weave fabric as the base fabric, with a surface density of 200g / m 2 , the warp and weft density is 304×316 (root / 10cm). The raw materials of the Z-shaped resin cured product made by injection molding are polycarbonate particles and short glass fibers. The preparation process of this anti-stab fabric is as follows: a, add short glass fibers in molten polycarbonate, utilize injection molding method to make Z-shaped polycarbonate cured product, the top view of Z-shaped resin cured product is a square with a side length of 20mm, The maximum thickness of the cured product is 5mm, and the minimum thickness is 2mm; b, evenly sprinkle hot melt adhesive powder on the garment fabric, and arrange the Z-shaped resin cured products neatly on the garment fabric, wherein the cured products are closely arranged between columns There is no gap, there is a gap of 1 mm and a height difference of 1 mm between the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com