Composite puncture-proof sheet and bulletproof puncture-proof composite material

A sheet, stab-proof technology, used in protective equipment, offensive equipment, textiles and papermaking, etc., can solve the problems of reduced comfort and high cost, and achieve the effect of reducing equipment weight, better effect, and good stab-proof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution proposed by the present invention will be further described below in conjunction with the embodiments, but not as a limitation to the technical solution. Any technical method that can realize the present invention constitutes a part of the technical solution related to the present invention.

[0031] Embodiment one

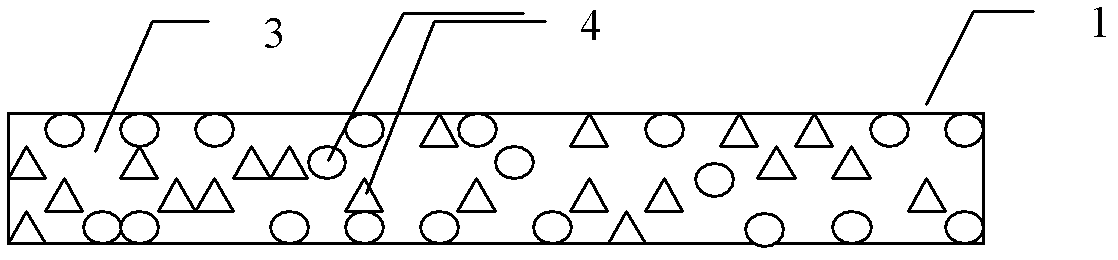

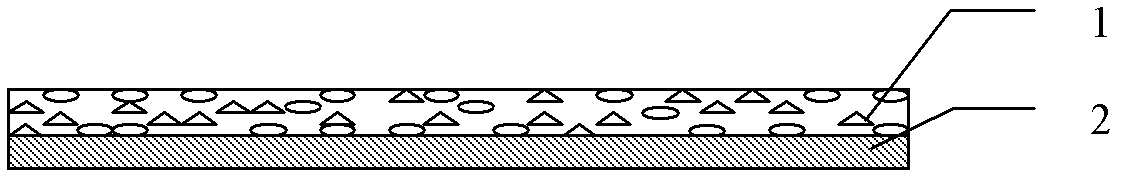

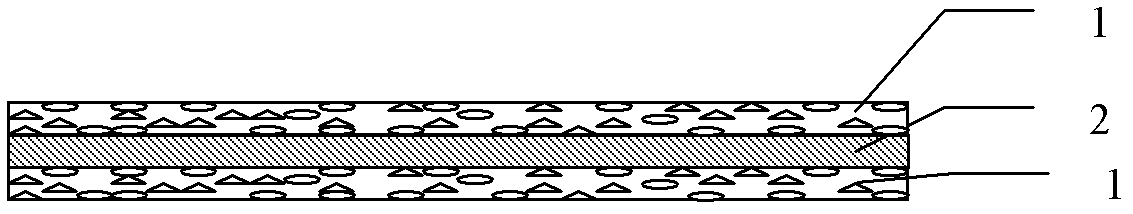

[0032] Composite anti-stab sheet coated with composite coating on one side, the structure is as attached figure 2 shown.

[0033] Take 100g of polyphenylene sulfide produced by Nanjing Deyuan Technology Co., Ltd., dissolve it in 100g of xylene to make a glue solution, and add 11g of glass beads with a particle size of 10nm (produced by Langfang Hongyuan Glass Bead Co., Ltd.) in 2 times into the glue solution, and slowly stir evenly to prepare the composite coating 1 glue solution. Take a piece of (200×200)mm cotton fiber three-way stitch-bonded fabric with a thickness of 0.05mm (produced by Guangzhou Shengxianya Co., Ltd., with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com