Guide ball-pin assembly

A technology of guiding balls and ball pins, applied in steering mechanism, steering rod, transportation and packaging, etc., can solve the problems of short service life, steering wheel trembling, easy radial loosening, etc., achieves less wear, increased friction surface, extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

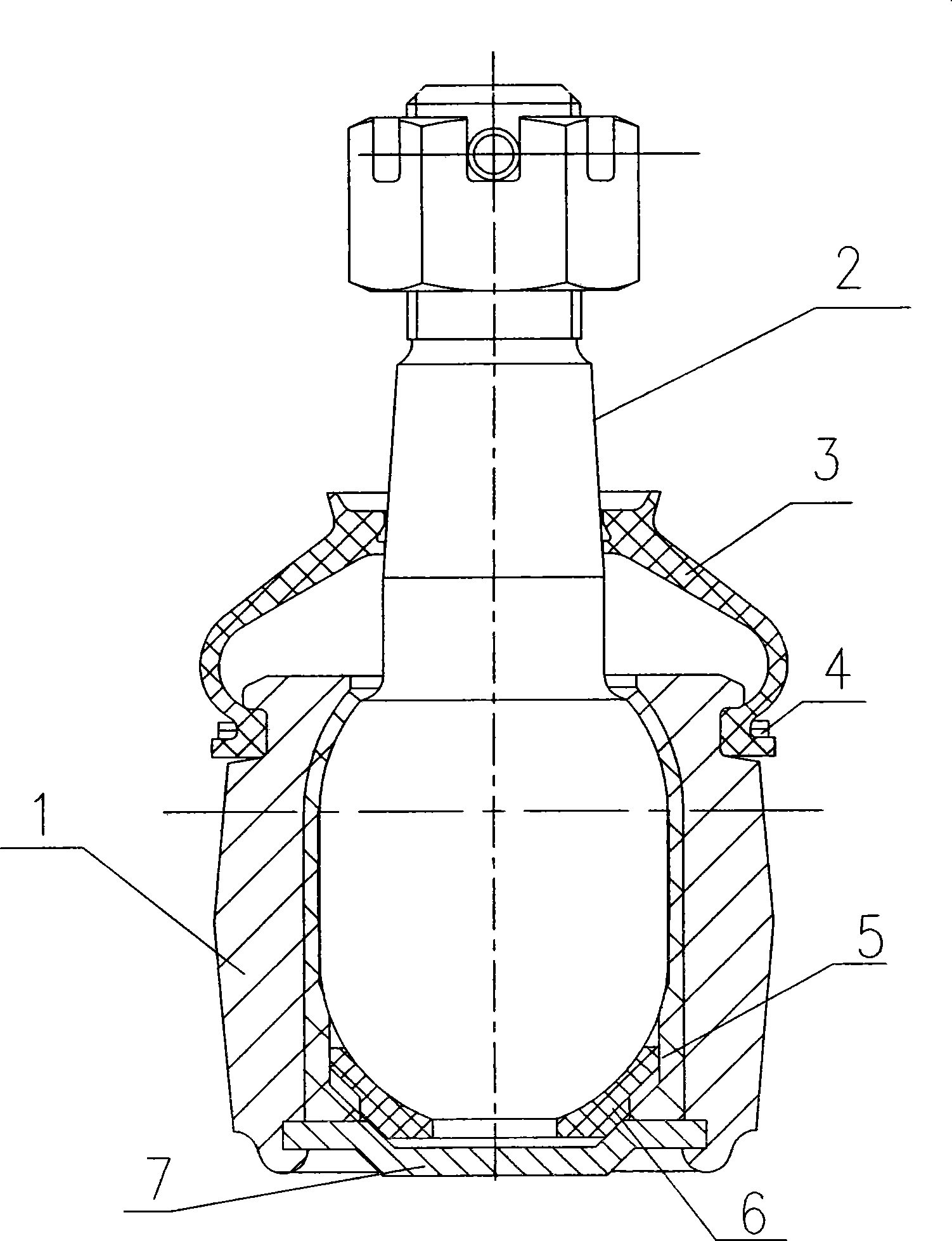

[0010] like figure 1 The invention shown is a guide ball pin assembly, including a housing 1, a ball seat installed in the housing 1 and a guide ball pin 2 installed in the ball seat, and the ball seat is installed in the housing 1 The large ball seat 5 inside is composed of the small ball seat 6 installed at the bottom of the large ball seat 5. The large ball seat 5 and the small ball seat 6 are combined to form a spherical cavity that matches the guide ball pin 2. The cover plate 7 is installed on the small ball seat. Below the ball seat 6, the cover plate 7 compresses the large ball seat 5 and the small ball seat 6 in the housing. The guide ball pin 2 is connected to one end of the dust cover 3, and the other end of the dust cover 3 is installed on the housing 1 through the collar 4. The guide ball pin 2 adopts a column type in which both ends are hemispherical and the middle is a cylindrical tube. ball pin. Large ball seat 5 and small ball seat 6 are used in cooperation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com