A low-speed diesel engine stuffing box internal sealing ring structure

A sealing ring and diesel engine technology, which is applied to the sealing device of the engine, mechanical equipment, engine components, etc., can solve the problems of increasing manufacturing difficulty, and achieve the effect of reducing the difficulty of processing technology, reducing the height, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the sealing ring inside the stuffing box of the low-speed diesel engine according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

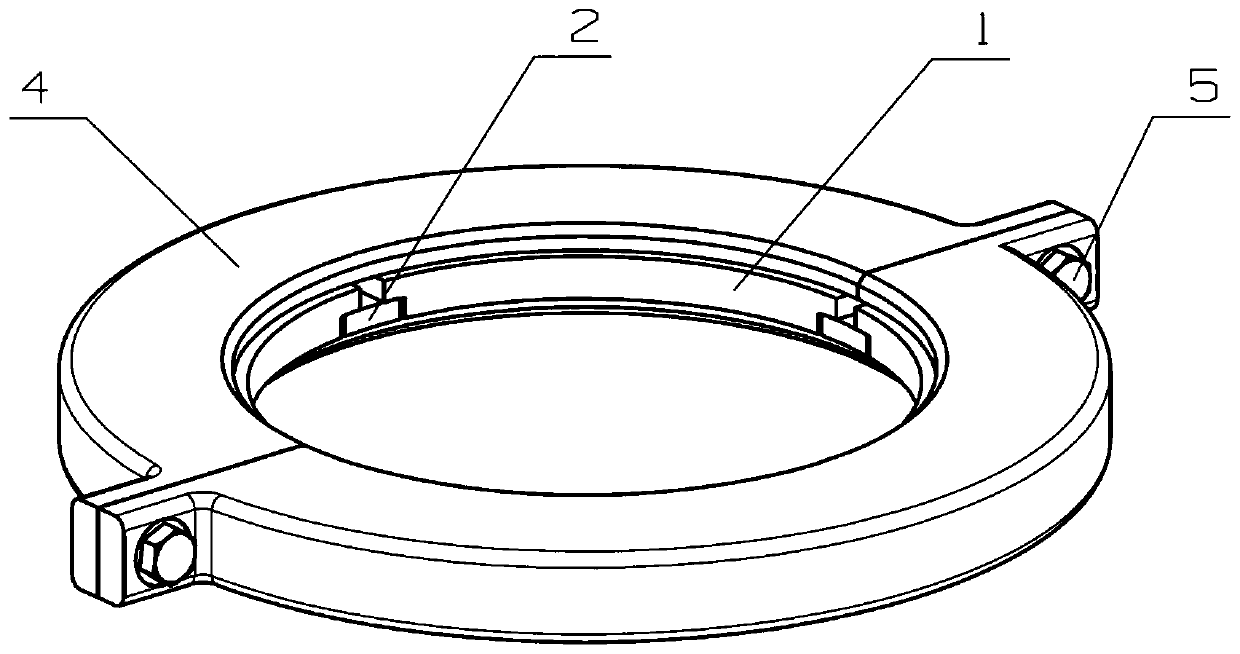

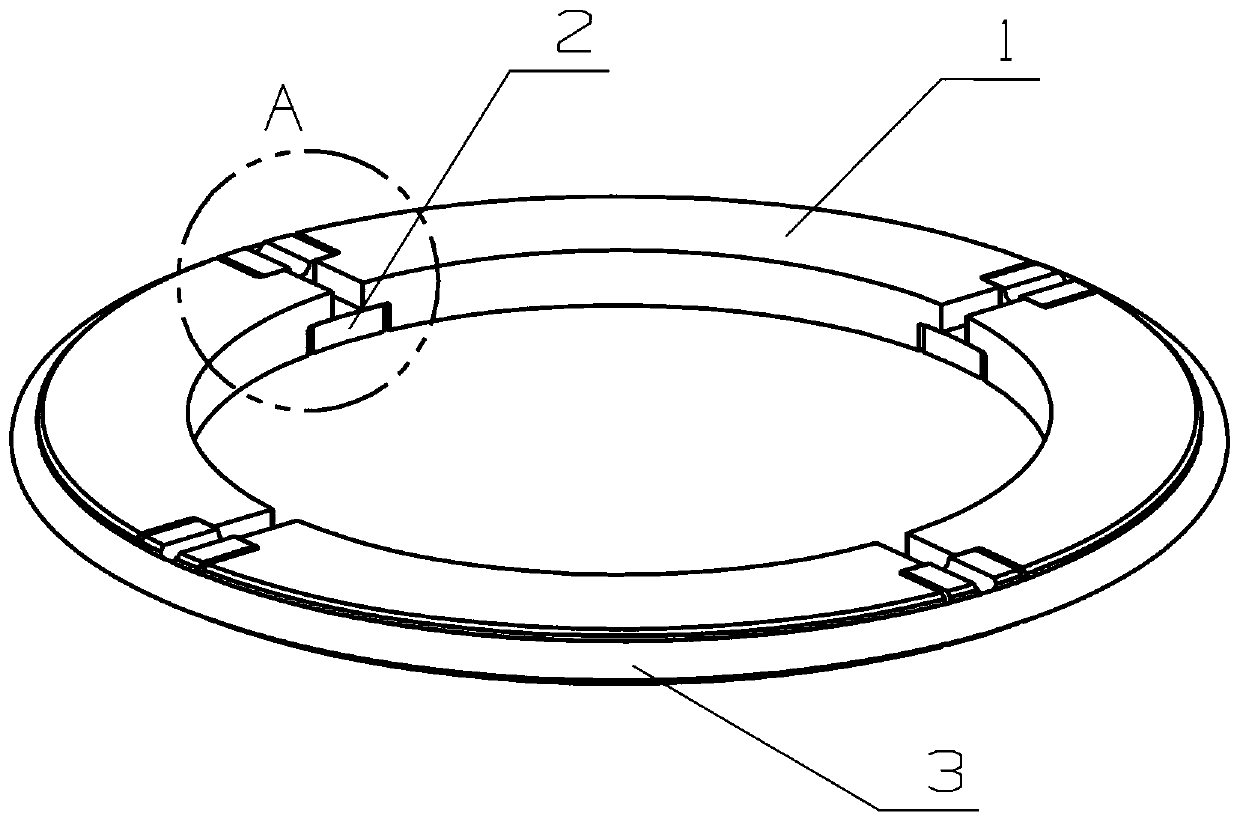

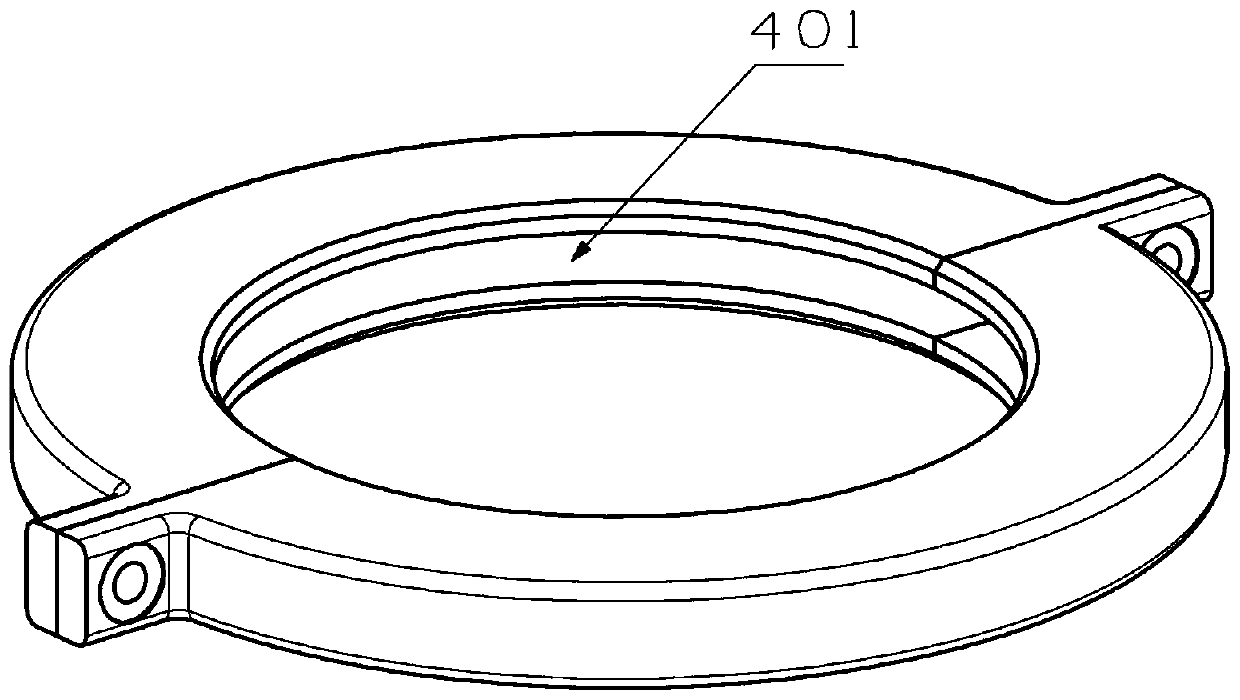

[0031] Please refer to figure 1 and figure 2 , which shows the internal seal ring structure of the low-speed diesel engine stuffing box, including four seal rings 1, four compensation blocks 2, spring 3 and housing 4.

[0032] Please refer to Figure 4 , Figure 5 and Image 6 , the four sealing rings 1 are the same and have the same size, and each sealing ring 1 is arc-shaped.

[0033] The sealing ring 1 is provided with an upper plane 105, a lower plane 106, an inner ring surface 101 and two side end surfaces 107, each side end surface 107 is provided with a protrusion, and the lower side of the protrusion is provided with a horizontal lower positioning T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com