Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

A technology of prefabricated components and prefabricated bodies, applied in building components, structural elements, building reinforcements, etc., can solve the problems of difficult quality control, affecting the strength of steel bar connections, and ineffectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be described in further detail below in conjunction with the accompanying drawings.

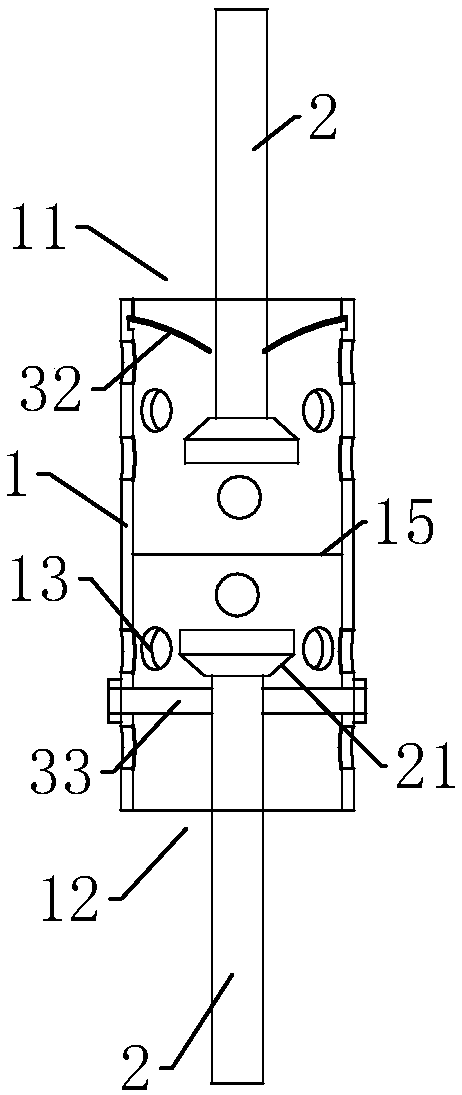

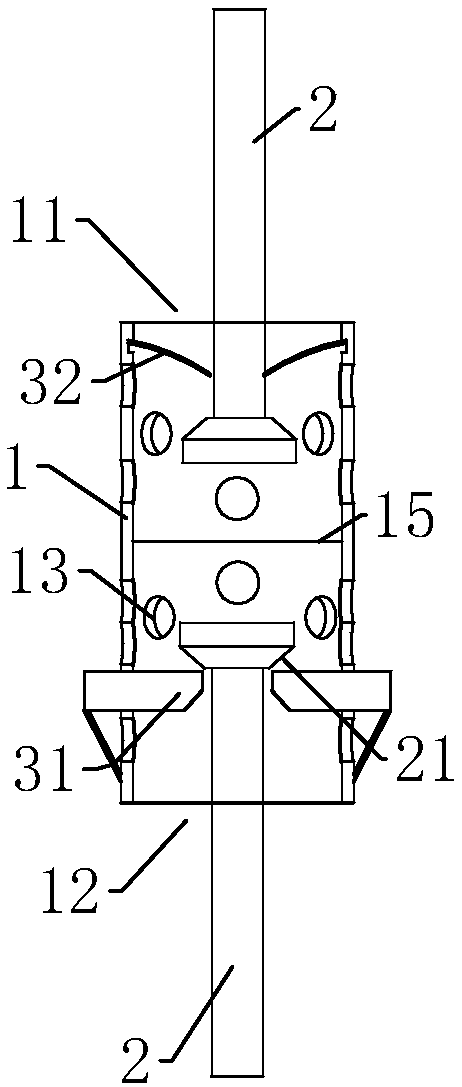

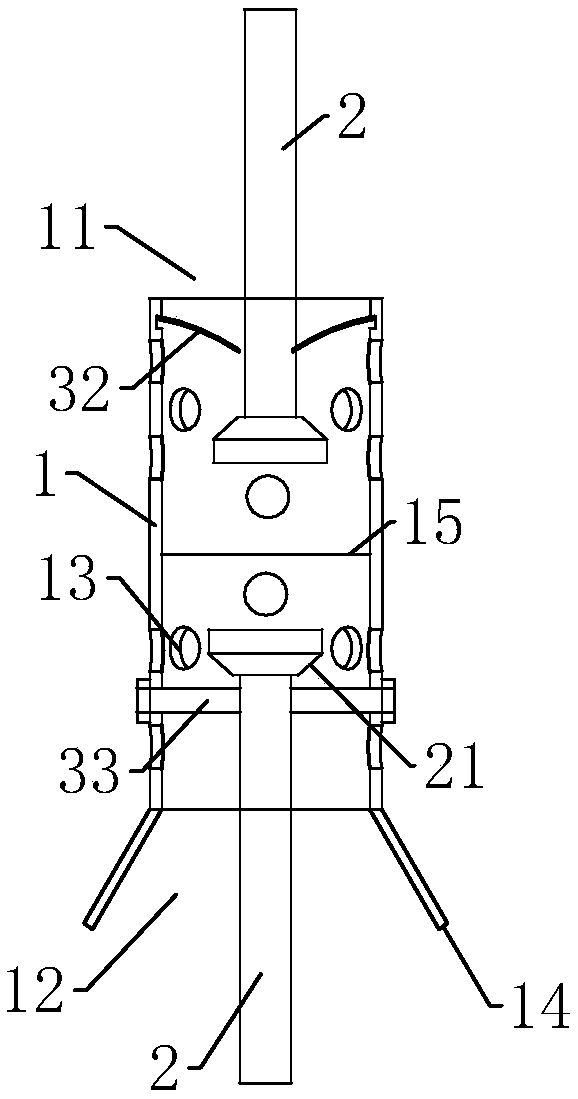

[0093] Figure 1-Figure 2 Two kinds of structural schematic diagrams of the sleeve 1 are shown, the elastic slip 32 is arranged in the basic port 11 of the sleeve 1, and the other end is specifically referred to in the illustration ( figure 1 The middle is the matching port 12 is the opening matching the positioning pin 33, figure 2The middle matching port 12 is an opening matching block 31). The matching port 12 is an opening, and additional structures such as positioning pins 33 and clamping blocks 31 provided at the opening assist the concrete in the sleeve 1 to bear the axial load of the steel bar 2 to improve the tensile strength of the sleeve 1 . When the slips 32 are assembled to the sleeve 1, an annular groove, an annular step surface or a groove is first processed in the circumferential direction on the inner cavity wall of the mating end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com