Tube used for refrigerating device and its processing method

A technology for a refrigeration device and a processing method, which is applied to non-removable pipe connections, pipes, rigid pipes, etc., can solve the problems of poor welding performance, leakage and fracture, increased energy consumption, etc. Good, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

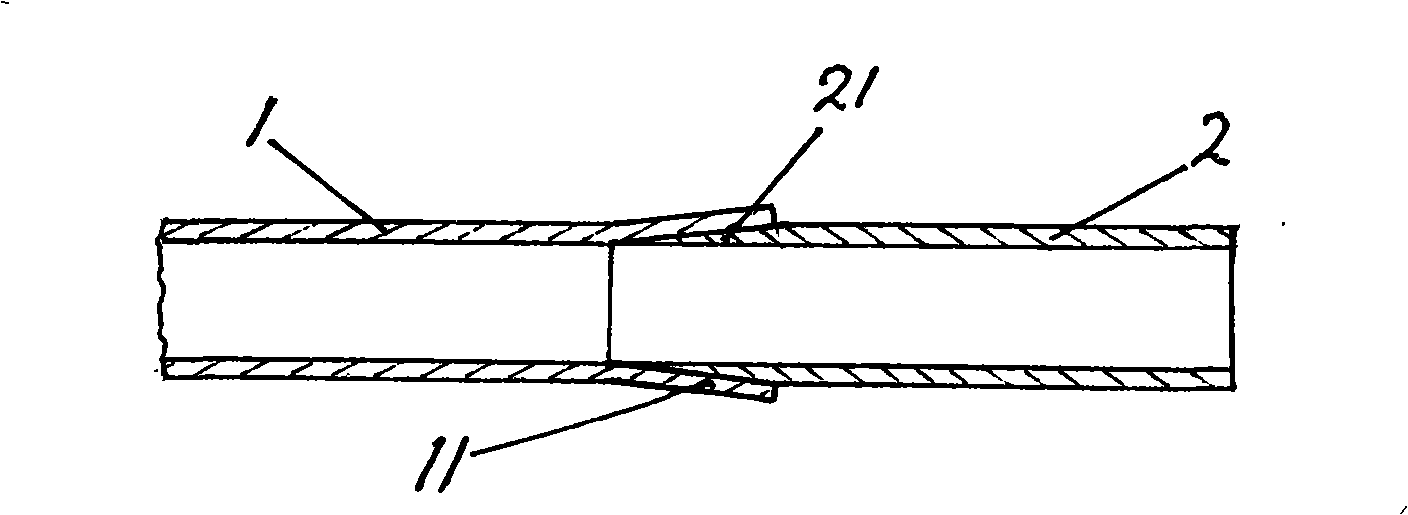

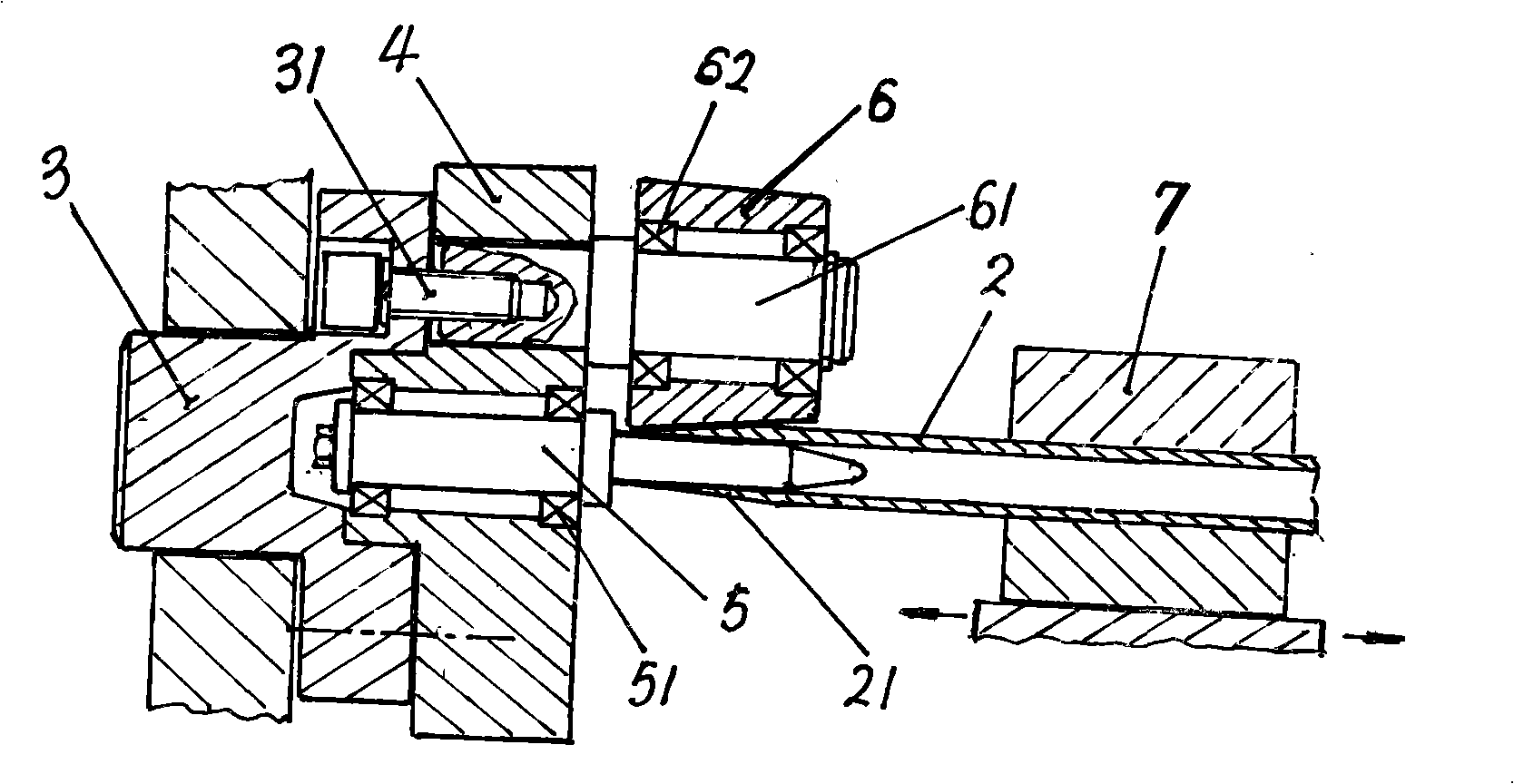

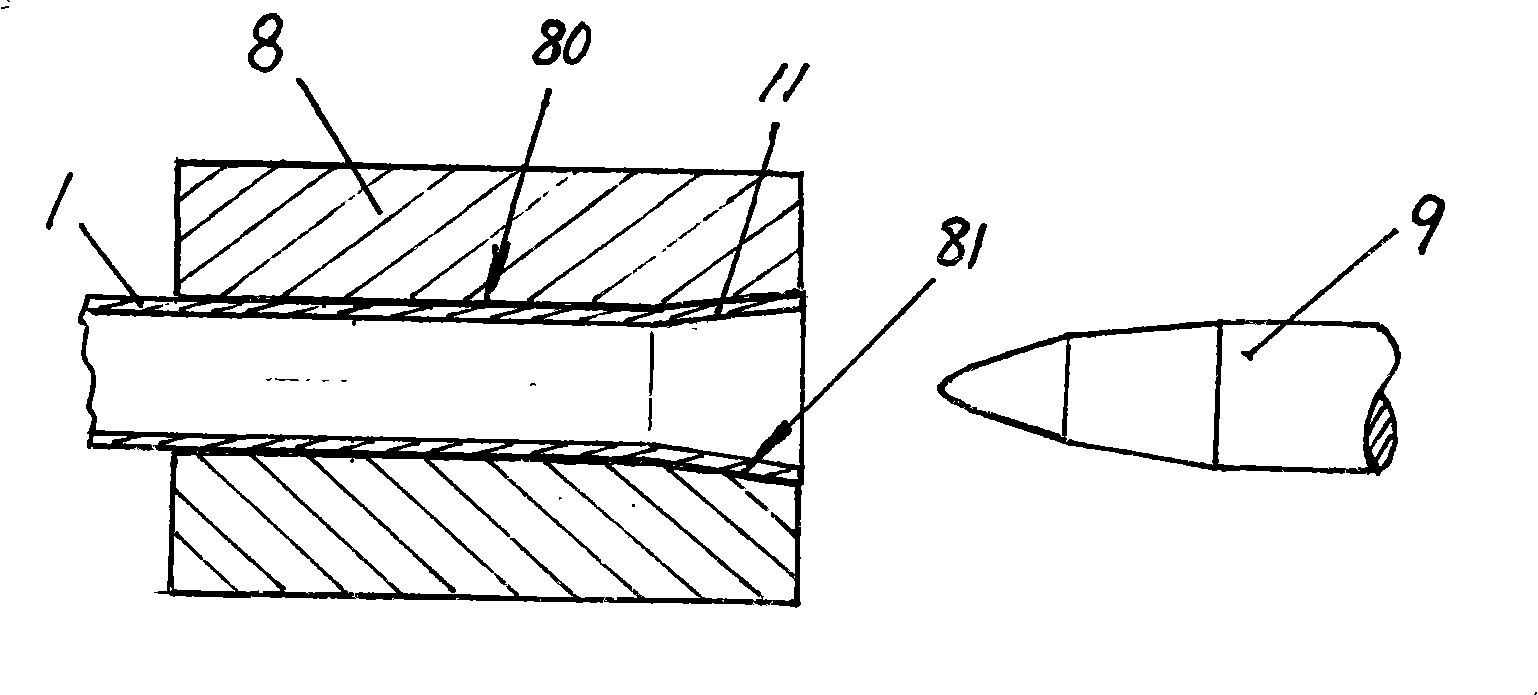

[0020] The butt joint processing method of the copper pipe 2 and the aluminum pipe 1 is as described above; the roller 6 of the cone extruder is installed on the roller 61 through the rotation of the bearing 62, and the roller 61 is installed in cooperation with the positioning mounting hole on the turntable 4, and is controlled by the chassis. The fixed bolt 31 on the 3 is fixed; the pipe clamp 7 is composed of the upper and lower two halves of the clamp to clamp the copper pipe 2; the expansion die 9 of the aluminum pipe 1 end is installed on the pneumatic device, the hydraulic transmission device or the punching machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com