Container

A container and neck technology, which is applied in the direction of containers, flexible containers, rigid containers, etc., can solve the problem of unable to obtain clamping force and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

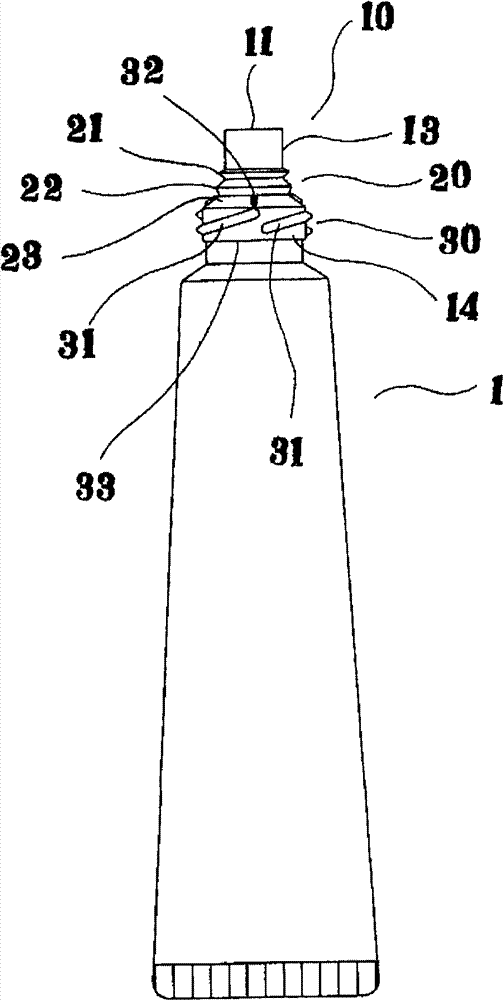

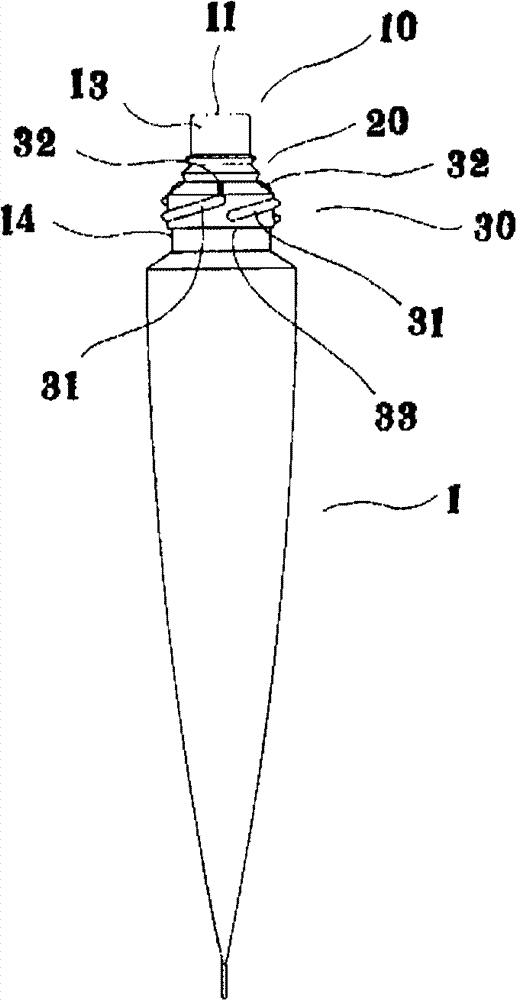

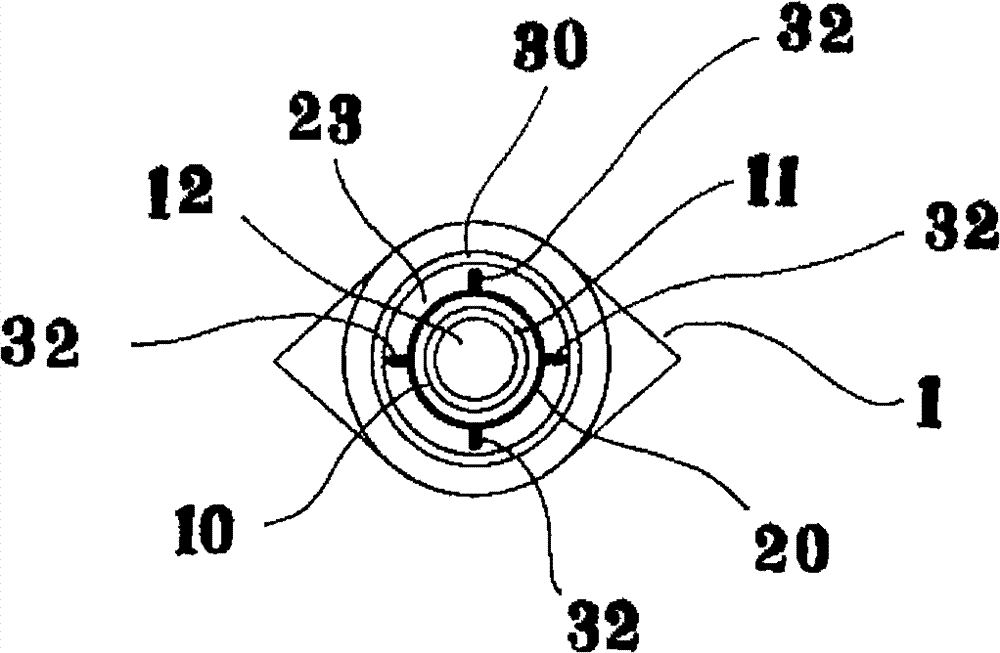

[0077] exist Figure 1 to Figure 5 In the shown embodiment, the container main body 1 related to the present invention is provided with a cap locking neck 30 whose inner and outer diameters are larger than the opening side neck 13 on the container shoulder side neck 14 of the container neck 10. Therefore, a large cap that is easy to hold can be used, and a strong locking force can be obtained by locking the neck 30 with a thicker cap, and a large amount of content can be accommodated in the neck Effect.

[0078] In addition, since the present invention has a structure in which extrusion flexibility is imparted to the cap locking neck portion 30, it is effective to squeeze and pour a large amount of contents accommodated in the neck portion.

[0079] In addition, since the present invention has the structure of imparting the compression recovery elasticity to the cap locking neck 30, it is possible to squeeze and pour a large amount of content contained in the neck, and the re...

Embodiment 2

[0081] In the case of the illustrated embodiment, the cap locking neck portion 30 is provided on the container shoulder side neck portion 14 having a larger diameter than the opening side neck portion 13 of the container neck portion 10 .

[0082] As for the outer diameter of the thick neck, the thicker the outer diameter of the thin neck, the larger the cap locking neck 30 can be provided, and a correspondingly larger locking effect can be expected.

[0083] The outer diameter of the thick neck is about 1.2 times or more than the outer diameter of the thin neck. Ideally, 1.6 to 2.4 times is suitable for ordinary caps, but it may be less than that for special containers and caps. or above.

[0084] In the case of the illustrated embodiment, the cap locking neck portion 30 is made of a threaded fixing structure, and four large-pitch external thread portions 31 are provided at intervals within 90 degrees and in a non-overlapping manner, so that The inner rotation completes the ...

Embodiment 3

[0087] In addition, a stopper 32 for preventing reverse rotation is provided on the cap locking neck portion 30 of the container neck 10, and the stopper 32 is used to securely fix the attached cap.

[0088] In the case of the illustrated embodiment, four stoppers 32 are provided at 90-degree intervals on the boundary portion 23 close to the neck portion 13 on the opening side, and the stoppers on the cover side, which are omitted in the figure, are installed. , engages across the stopper 32 and prevents reverse rotation of the cover.

[0089] In addition, in the embodiment of the present invention, the stopper 32 is configured with a single-click stop-type engagement structure by engaging with the elastic deformation and releasing the elastic force, so that the stopper 32 can be fixed with a single-click feeling. cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com