Jacquard machine assembly device

A unit and insert technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve problems such as difficulty in controlling the spring force of the vertical hook spring, high contact pressure of the moving iron shaft, wear and tear of the vertical hook spring, etc., to achieve The effect of overcoming control difficulties, avoiding failure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

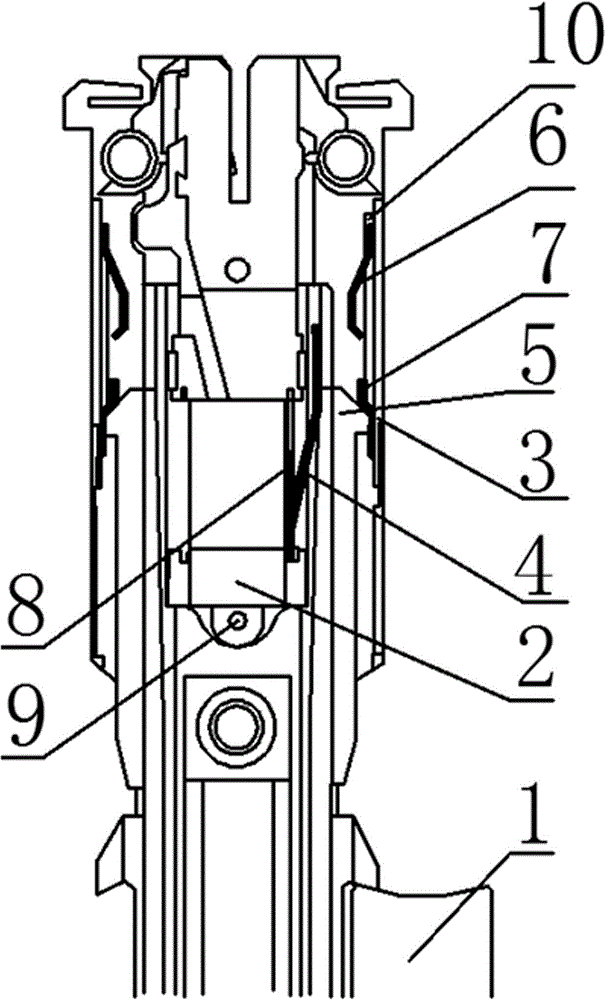

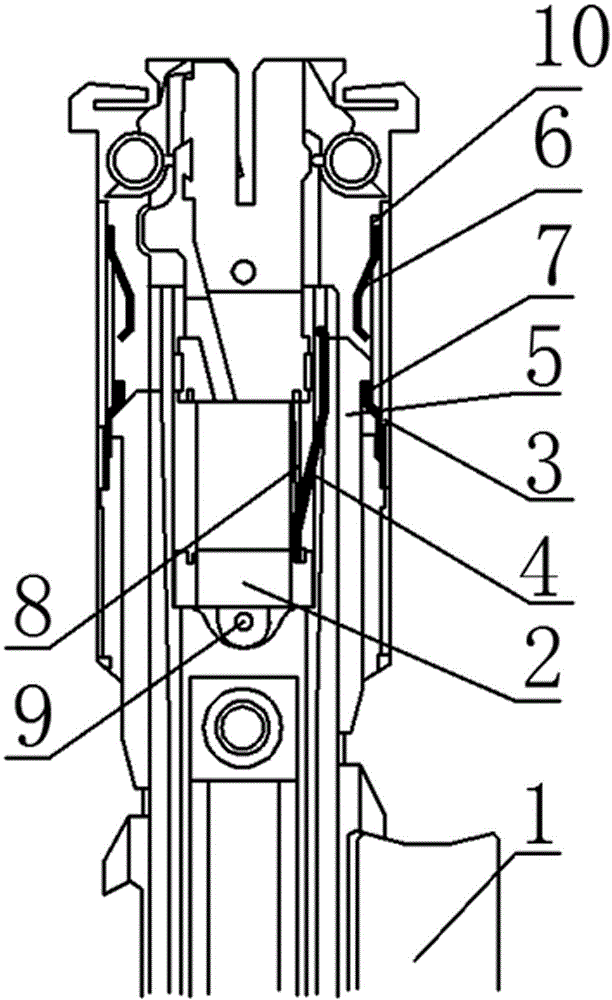

[0013] With reference to the accompanying drawings, a jacquard machine component device includes a broach 1, an electromagnet 2, a splint 3, a return spring piece 4, a moving iron vertical hook 5, an auxiliary suction spring piece 6 and a return spring piece hook 7, and the broach 1 is installed on the jacquard machine, the electromagnet 2 is installed on the splint 3, the electromagnet is fixed by the positioning pin 9, the return spring piece 4 is installed on the electromagnet 2, and the moving iron vertical hook 5 is installed on the Between the two splints 3, the moving iron vertical hook 5 is driven by the broach 1 to slide in the T-shaped groove formed by the two splints 3, and the moving iron vertical hook 5 is injected with a soft magnetic insert inside, and the soft magnetic One side of the insert is exposed outside, the splint 3 is provided with a return spring leaf hook 7, and an auxiliary suction spring leaf 6 is installed above the return spring leaf hook 7.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com