Sleeve, prefabricated part connector, prefabricated part and prefabricated part assembly

A technology of prefabricated components and prefabricated bodies, applied in building components, structural elements, building reinforcements, etc., can solve the problems of high connection strength, small market application range, and poor structural connection integrity/air tightness/seismic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

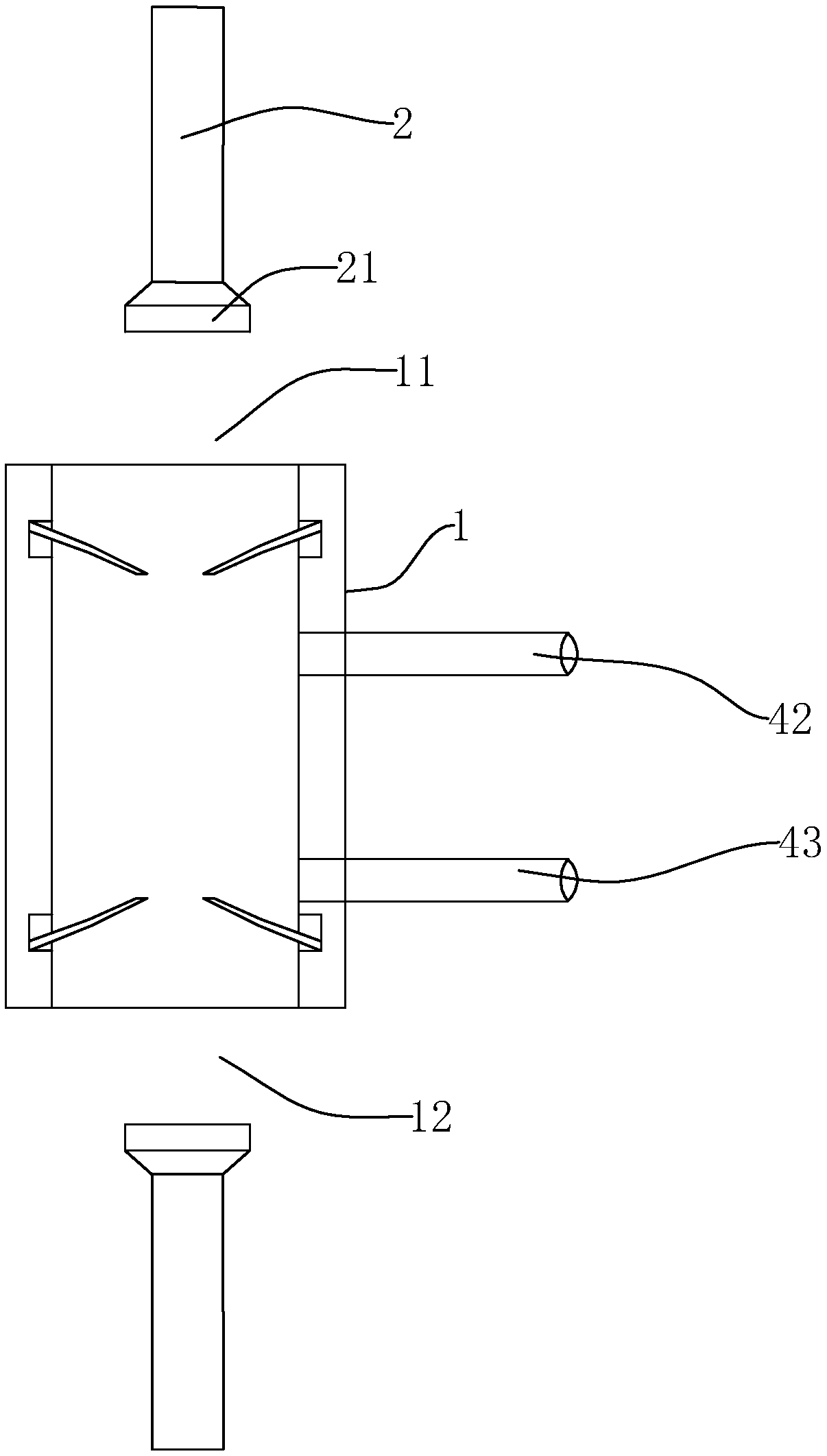

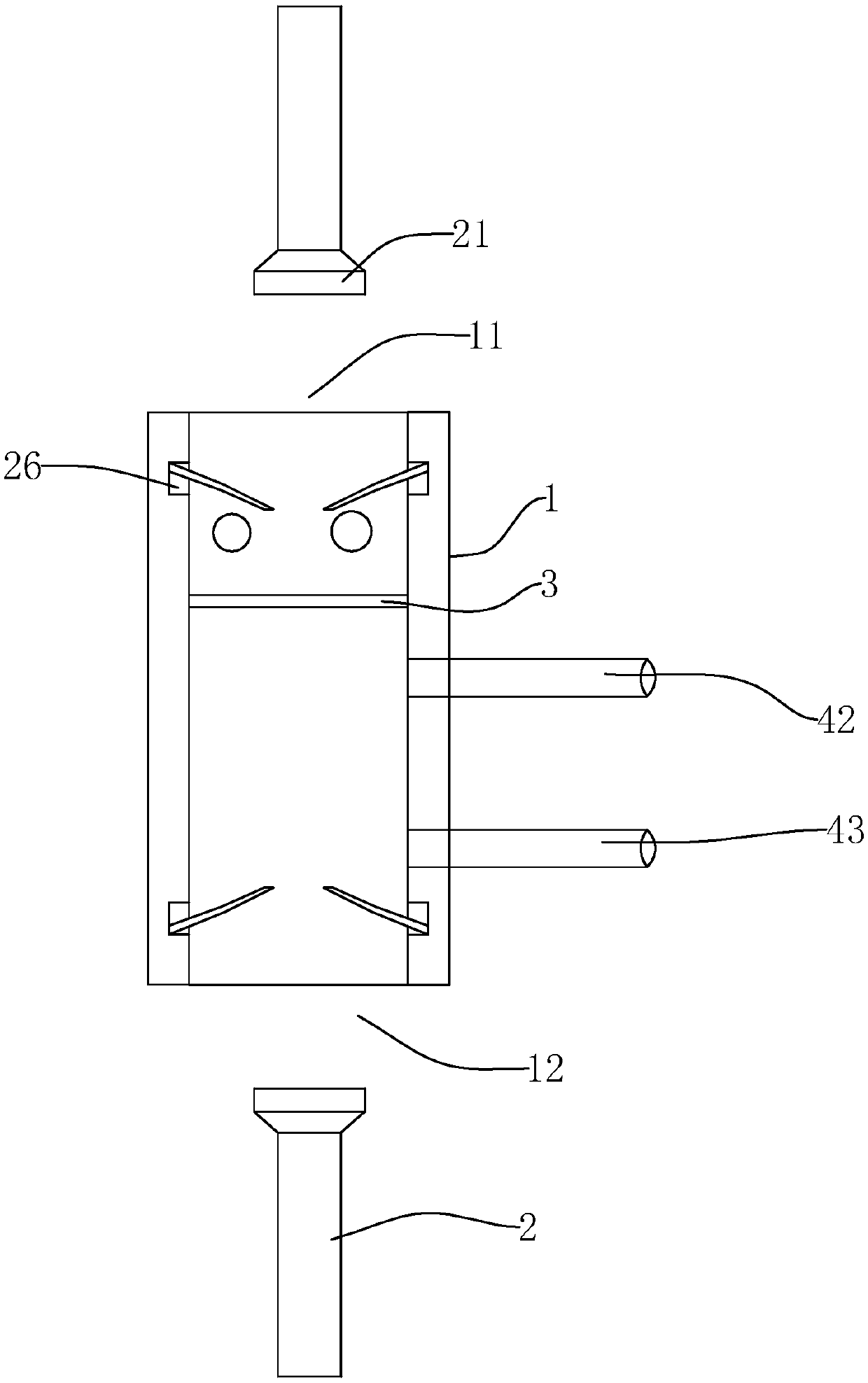

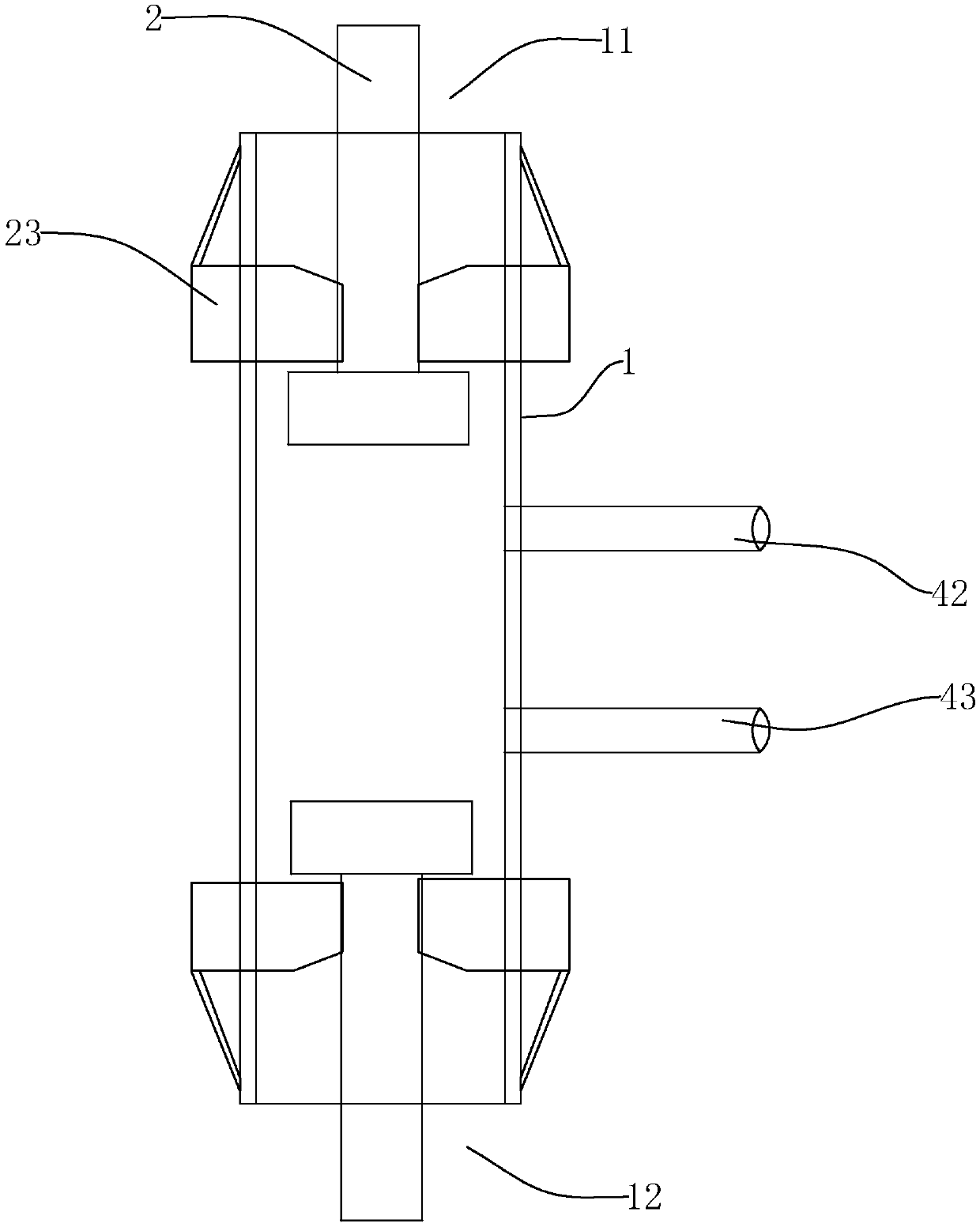

[0084] Example: Figure 1-Figure 5 The schematic diagrams of the six structures of the sleeve 1 are given as shown, and the clamping connection of the ports at both ends of the sleeve 1 port is shown in the figure. Figure 1-Figure 2 The clamping part of the middle port is an elastic slip 24, Figure 3-Figure 4 The clamping part of the middle port is the clamping block 23, Figure 5-Figure 6 The fastening part of the middle port is an end cap 25 threadedly connected with the port. The clamping piece at the port of the sleeve 1 can cooperate with the structure of the enlarged head 21 or the bending structure at the end of the steel bar 2 to increase the tensile strength of the sleeve 1 . When the clamping parts provided at the ports are elastic slips 24, clamping blocks 23 and end caps 25, etc., the concrete or grouting material in the auxiliary sleeve 1 is axially loaded by the steel bar 2 to improve the tensile strength of the sleeve 1. When the slips 24 are assembled to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com