Blind hole polishing device for dental implants

A dental implant and polishing device technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problem of machining accuracy and matching accuracy affecting implant stability and service life, and affecting restoration effect, etc. problem, to achieve the effect of guaranteed polishing effect, convenient realization, and convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

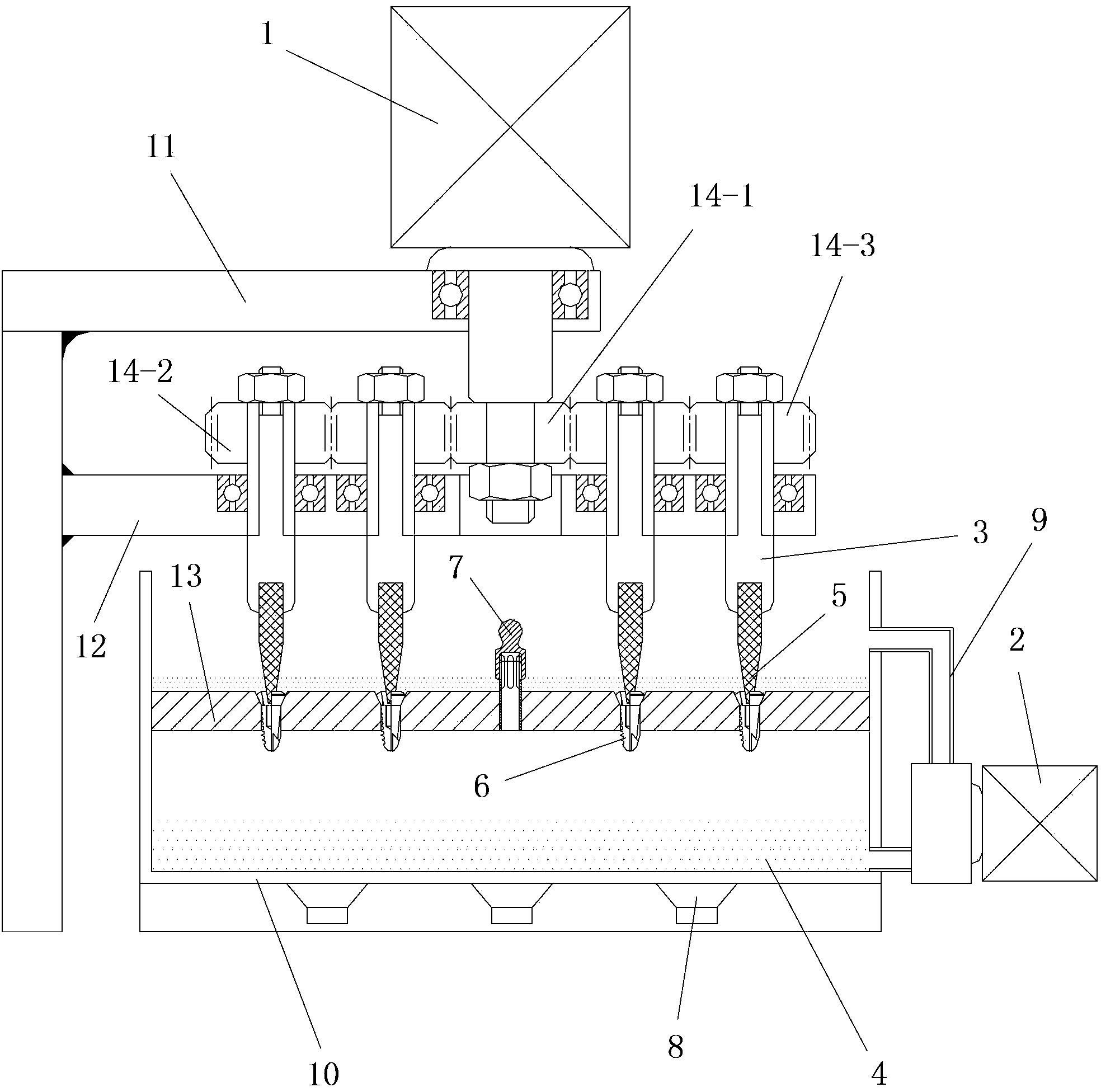

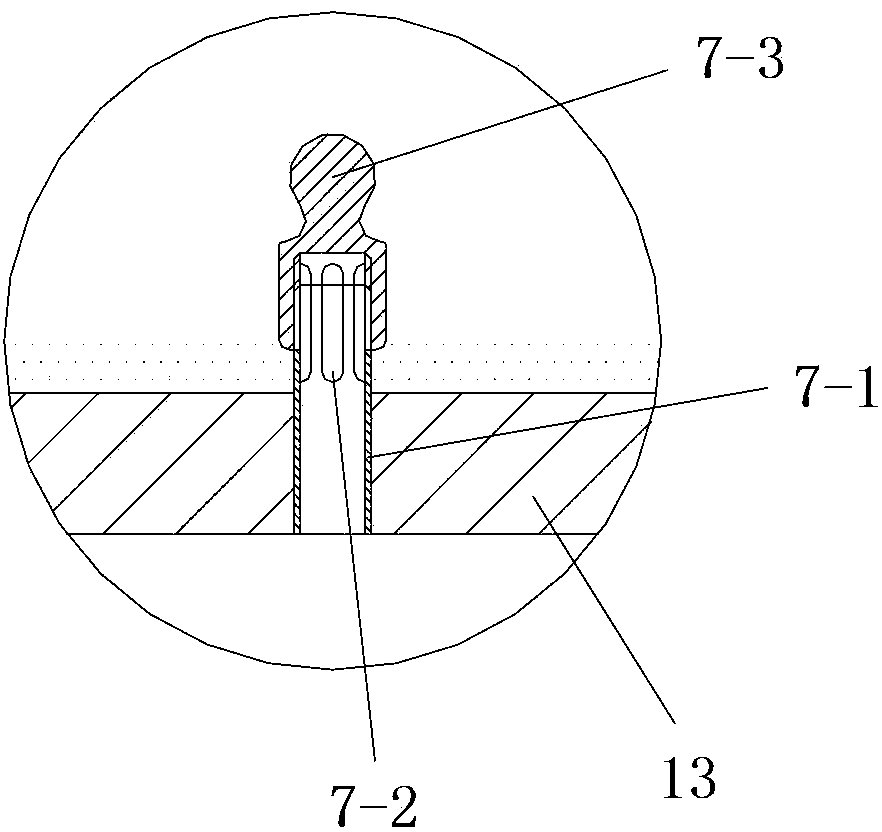

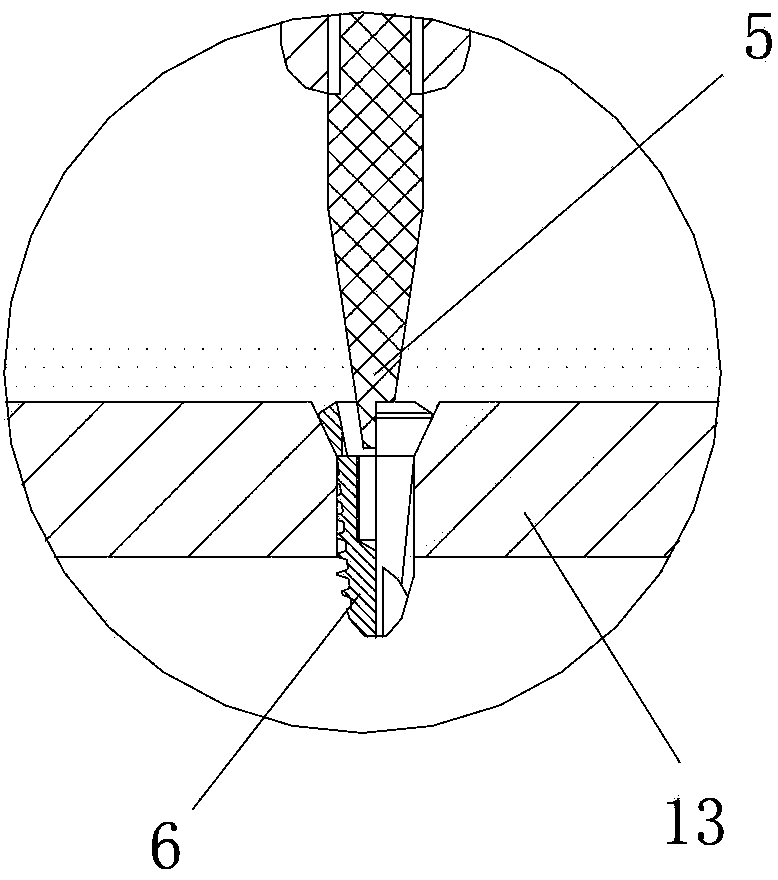

[0044] like figure 1 and image 3 A dental implant blind hole polishing device shown in the present invention includes a polishing tank 10 arranged horizontally and equipped with a polishing liquid for dental implant mirror polishing inside, installed horizontally on the middle and upper part of the inner side of the polishing tank 10 and for multiple The polishing table 13 installed on the processed dental implant 6, a plurality of polishing heads 5 for polishing the blind holes set in the middle of each processed dental implant 6, a drive motor for synchronously driving a plurality of the polishing heads 5, and A fixed bracket 12 arranged above the polishing table 13 for mounting a plurality of polishing heads 5, the polishing table 13 is provided with a plurality of vertical polishing pads for respectively mounting a plurality of dental implants 6 to be processed. The plurality of vertical polishing holes have the same structure, and the plurality of vertical polishing hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com