Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

A technology of prefabricated components and prefabricated bodies, applied in building structures, building materials, buildings, etc., can solve the problems of complex operation technology, difficult construction operation, and inefficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

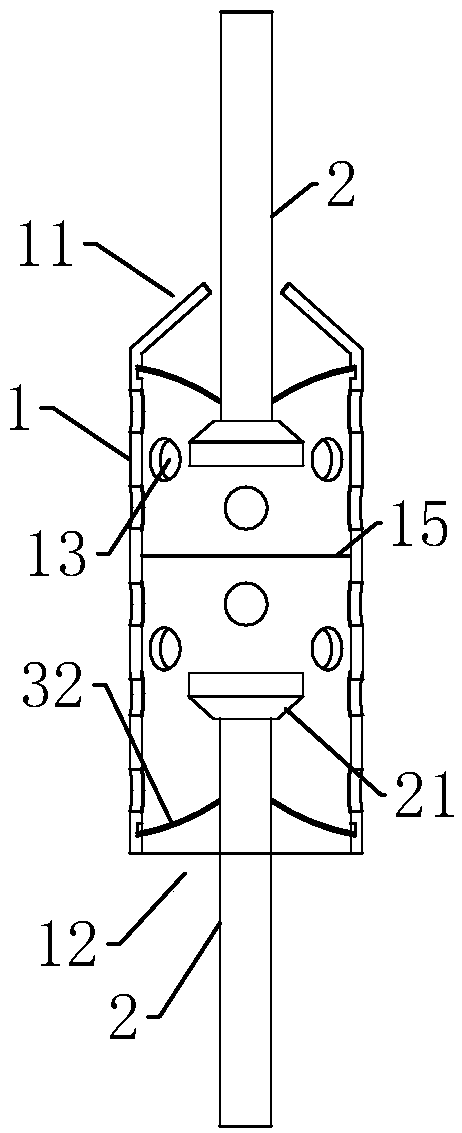

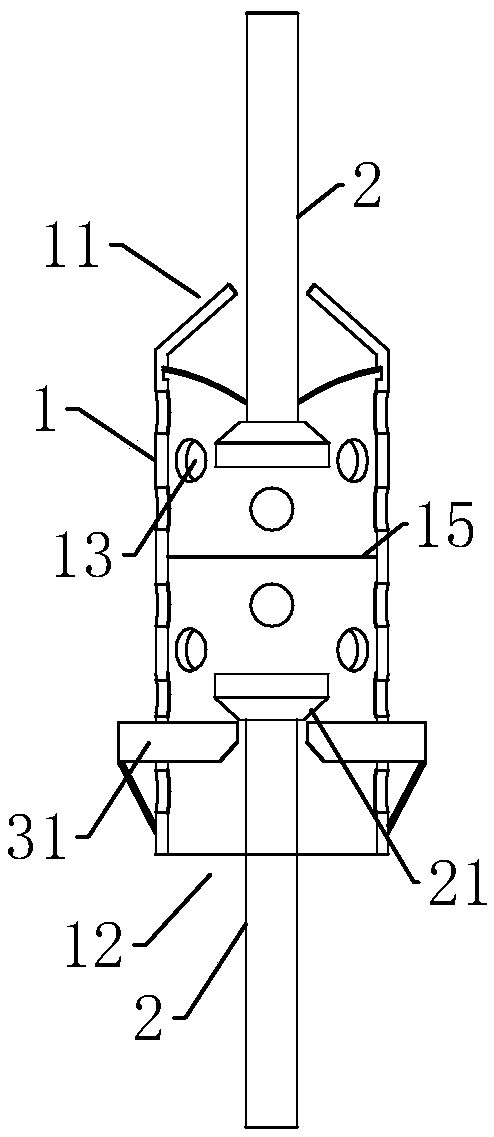

[0098] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0099] In the prefabrication process, one end of the sleeve 1 is closed first, and the taper of the closing is the same as that of the expanding head 21 at the end of the steel bar 2. After matching the concrete grout injected into the sleeve 1, the expanding head 21 at the end of the steel bar 2 is aligned with the concrete. The generated stress is finally transmitted to the tapered mouth of the foundation port 11, and the axial tensile force on the steel bar 2 is divided into two directions, horizontal and vertical, at the sleeve 1, thereby increasing the axial tensile strength of the sleeve 1. The opening at the other end forms a locking fit with the enlarged head 21 and the bending structure 22 formed at the end of the steel bar 2 through the clamping piece, and the axial tensile strength of the sleeve 1 is increased together with the concrete poured into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com