Sleeve, prefabricated component connector, prefabricated component and prefabricated component assembly

A technology of prefabricated components and prefabricated bodies, applied in the direction of building components, structural elements, building reinforcements, etc., can solve problems such as invalidity, poor corrosion resistance/durability, and difficulty in ensuring connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

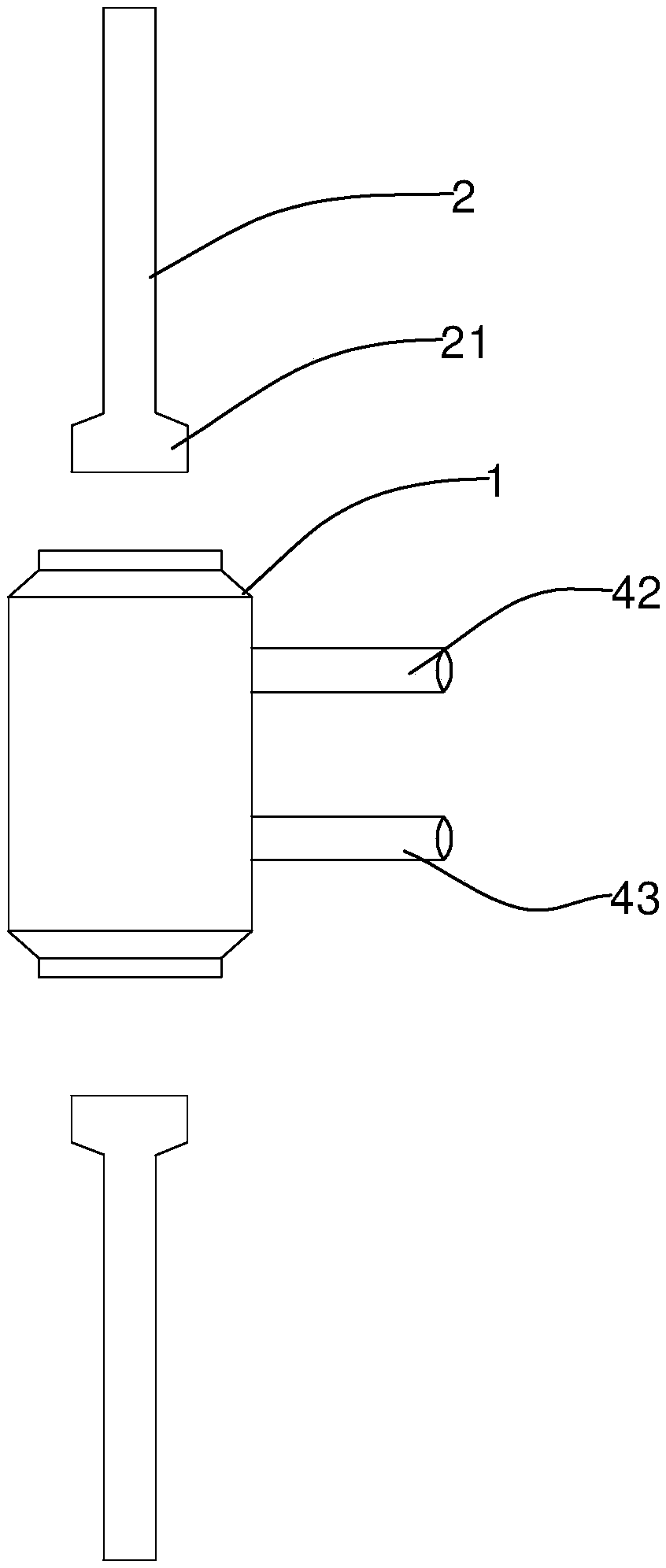

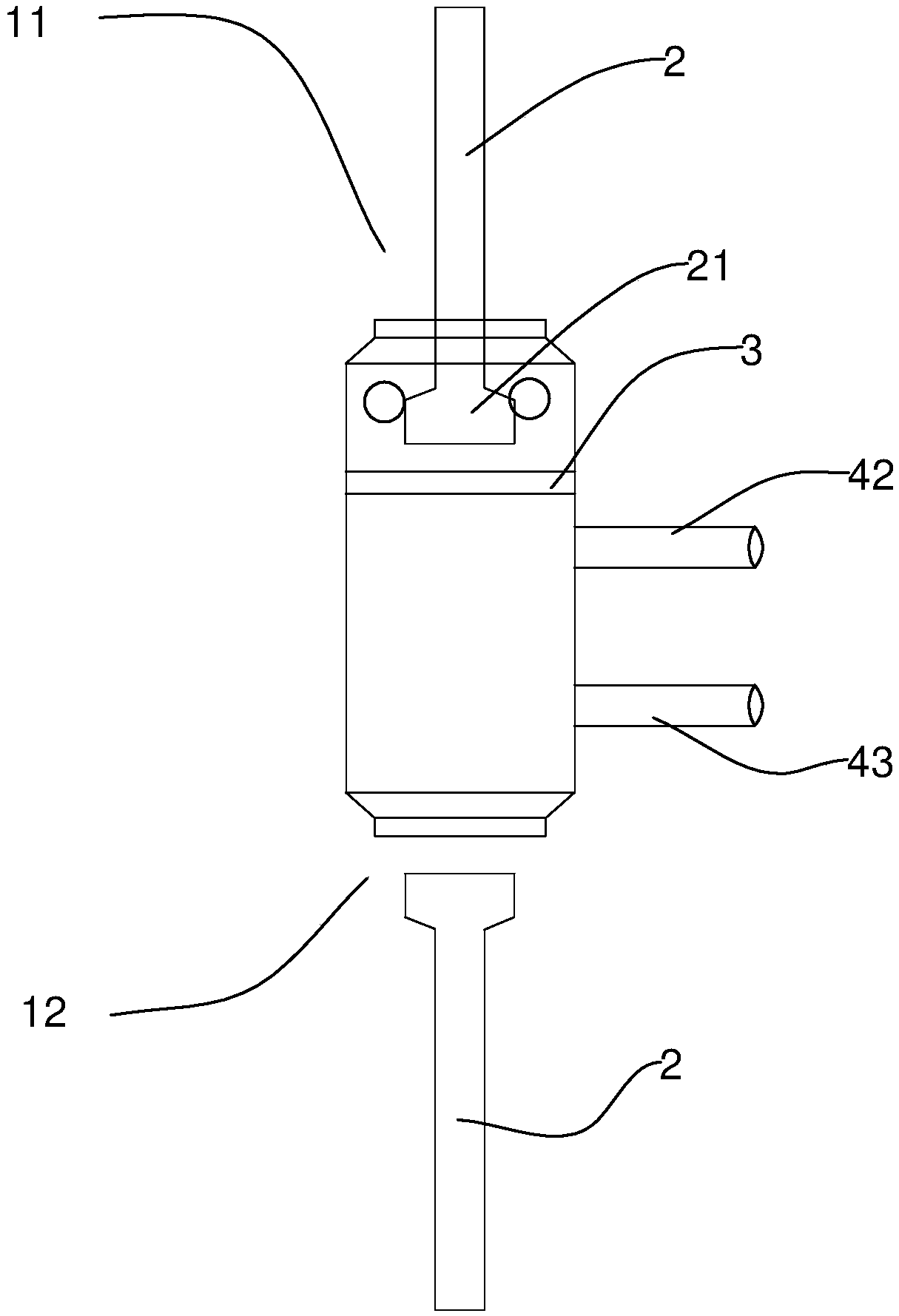

[0080] Example: Combine figure 1 , the ports at both ends of the sleeve 1 are closed, and the closed is tapered, and the end with the larger diameter of the closed section faces the direction of the cylinder. The cylinder body of the sleeve 1 is provided with a through hole extending outward to form a grouting channel 42, which can allow concrete grout or grouting material to enter the inner cavity of the sleeve 1, and the cylinder body is provided with a through hole extending outward to form an exhaust channel 43. It can avoid the formation of air bubbles in a closed space between the concrete grout or grouting material and the inner wall of the sleeve 1, reduce the compactness of the concrete grout or grouting material, and ensure the axial tensile strength of the sleeve 1 as a connecting node.

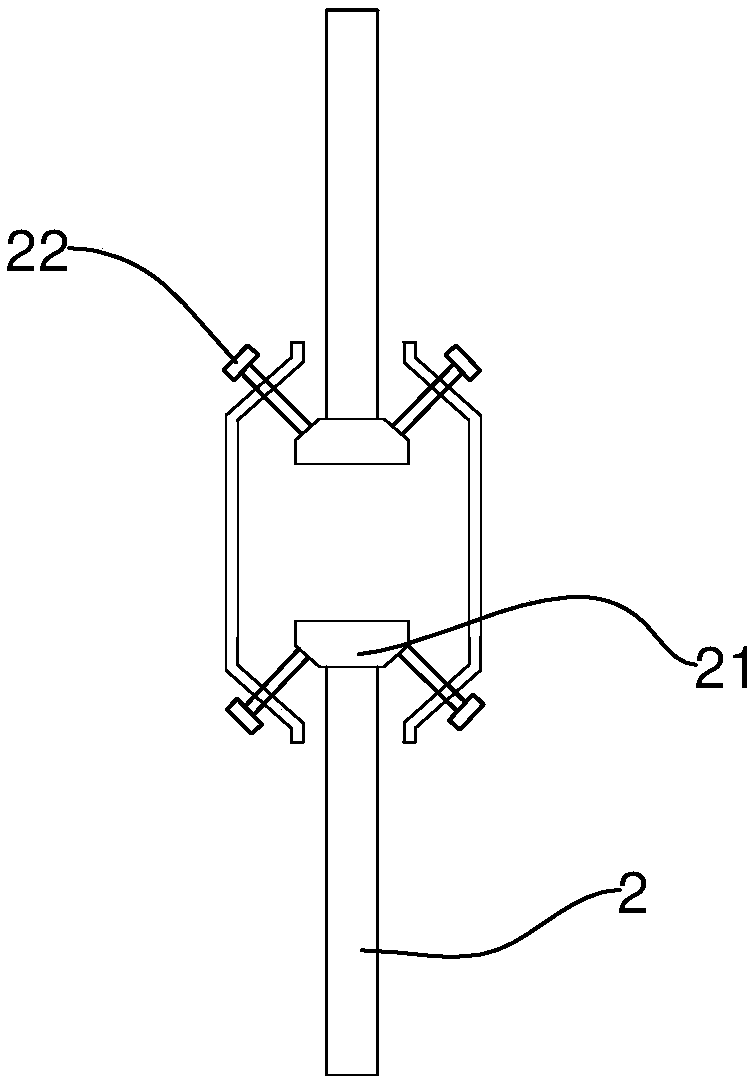

[0081] The barrel of the sleeve 1 is provided with a partition 3 perpendicular to the axial direction, and the partition 3 divides the barrel into two parts, see figure 2 , one p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com