Cushion pad support assembly suitable for passenger car back door

A technology for cushioning pads and passenger cars, which is applied to doors, vehicle components, and non-rotational vibration suppression. It can solve the problems that the cushion pads cannot be well matched with the car body, and achieve an effect that is conducive to processing and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

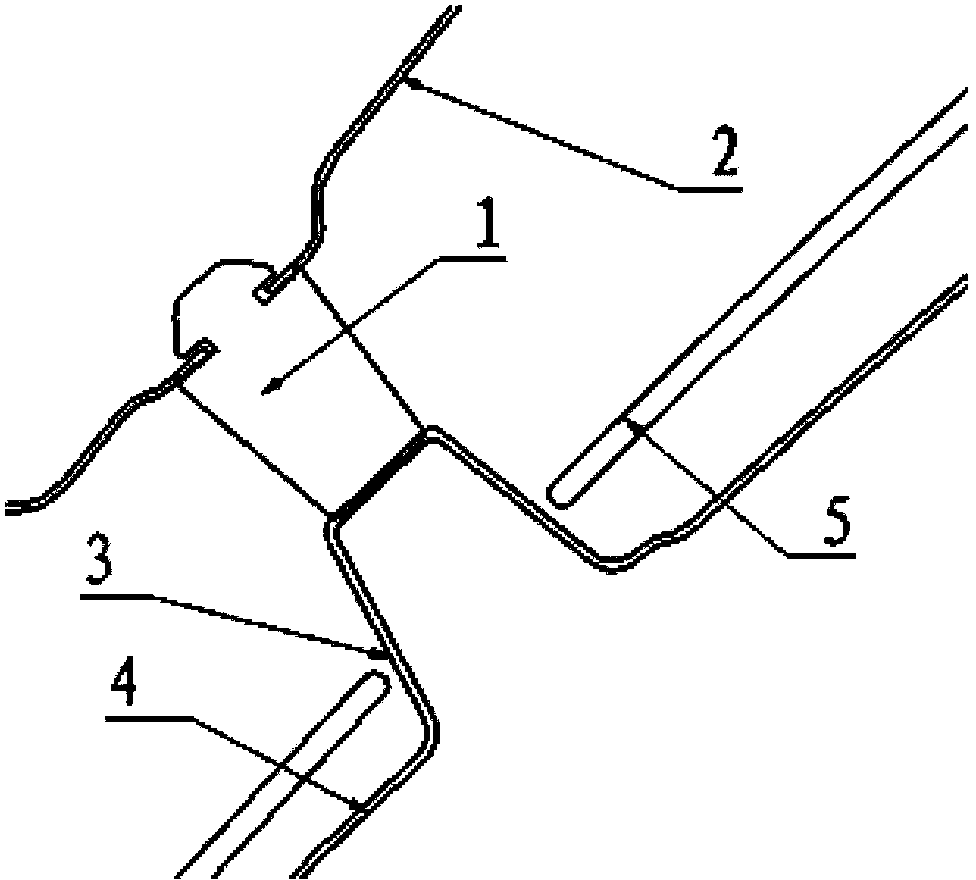

[0014] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

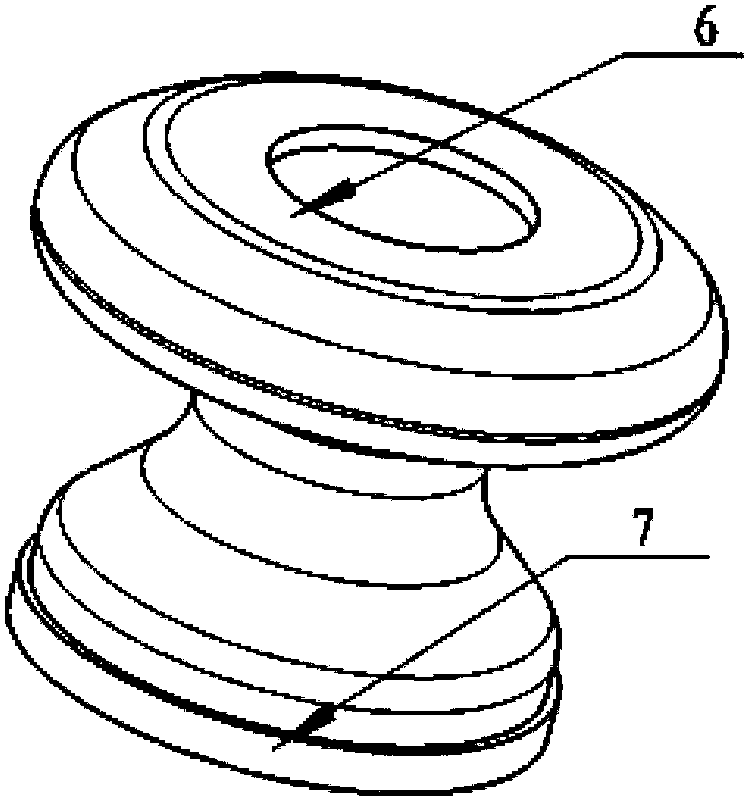

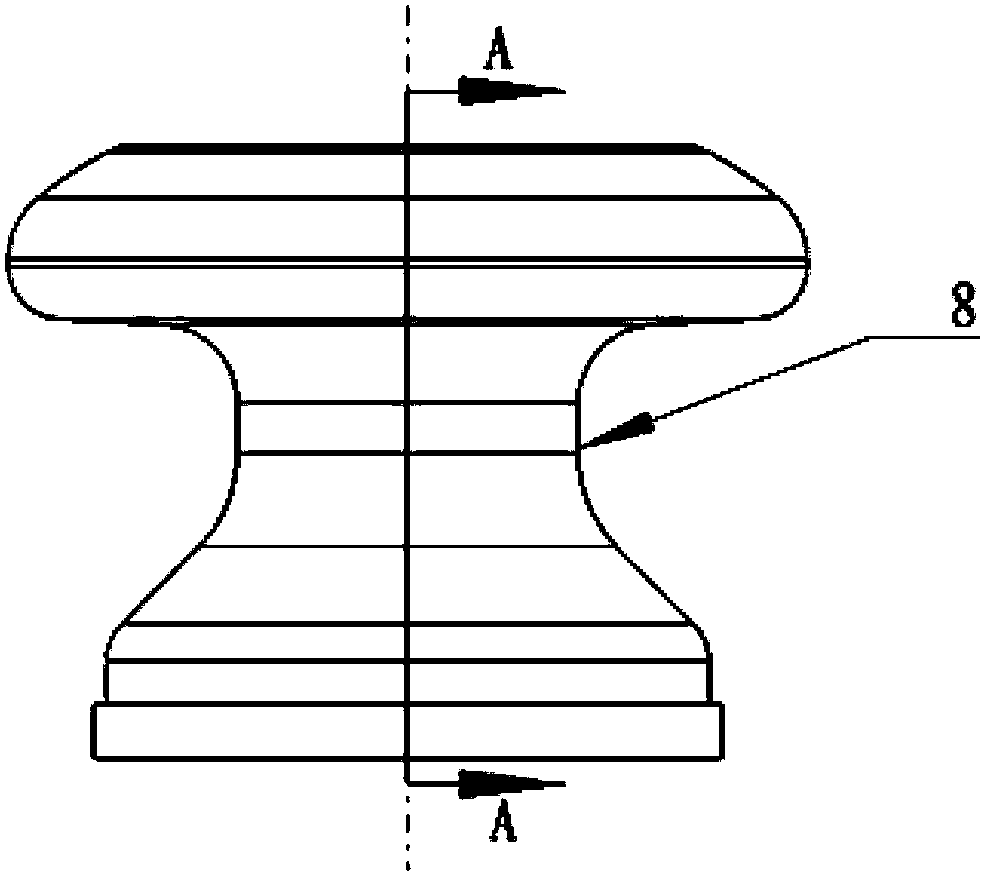

[0015] Such as figure 2 , 3 As shown in and 4, the cushion support assembly is a waist drum-shaped structure 8, including a cushion support 6 and a support waterproof pad 7, the bottom of the cushion support is pasted and connected with the support waterproof pad, and the cushion support There is a through bolt hole 9 in the center of the assembly, and the top of the bolt hole is a counterbore structure, and the depth of the counterbore is consistent with the thickness of the bolt pan head. The top of the head is level.

[0016] The lower part of the buffer pad support is expanded into an avoidance hole 10 whose diameter is greater than that of the bolt hole. The cushion support can be made of PC+ABS material, and the waterproof pad of the support can be made of closed-cell foamed EPDM material.

[0017] In order to ensure the airtightness of the fit, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com