Seal assembly for hub bearing unit

A technology for wheel hub bearings and sealing components, applied in bearing components, shafts and bearings, engine components, etc., can solve the problems of grease spillage, large friction torque, grease pollution, etc., achieve efficient dynamic sealing, increase difficulty, and avoid coordination failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

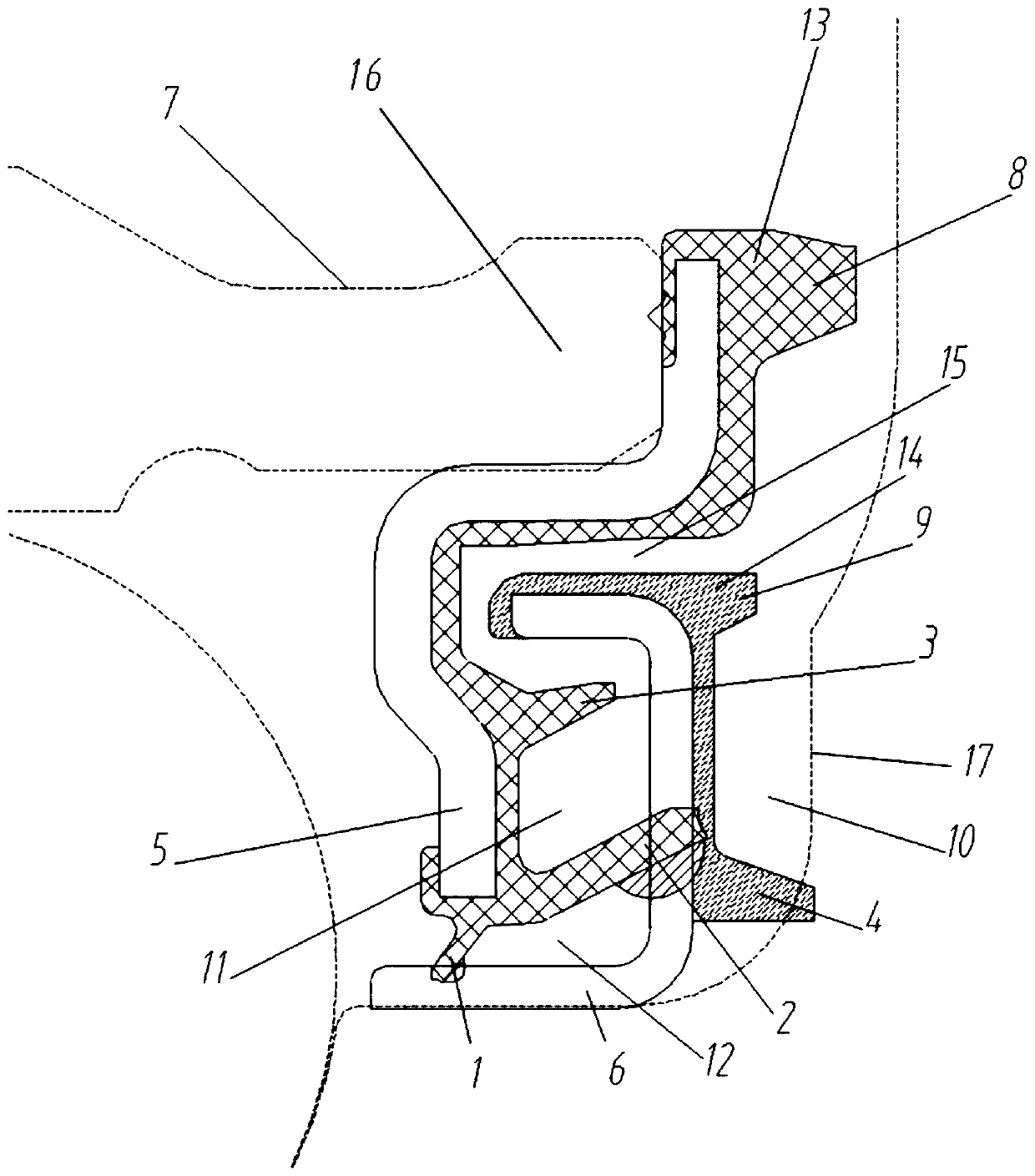

[0009] The present invention will be described in detail below in conjunction with the drawings:

[0010] Example: As shown in the drawings, this kind of sealing assembly for a hub bearing unit includes a stationary frame 5 arranged on the outer ring 16 and a rotating frame 6 arranged on the flange plate 17, which is between the outer ring 16 and the flange plate 17. A raceway is formed between the raceways and a cavity is formed on the outside of the raceway. The surface of the outer ring 16 is provided with a groove 7; the stationary frame 5 is provided with an outer rubber A13 with rubber protrusions A8; the rotating frame 6 The outer covering rubber B14 with rubber protrusion B9 is set outside, and the rubber protrusion B9 is flush with the rubber material under the rubber protrusion A8, so that the sewage entering between the rubber protrusion A8 and the flange 17 is drained to the rotating skeleton 6 and the flange 17 formed in the cavity A10; the head of the rotating frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com