Method and system for extracting gold from arsenic contained headings

A technology for gold concentrate and gold, which is applied to the gold extraction system and the field of fine-grained gold extraction, can solve the problems of prolonging the operation time, the purity cannot meet the product requirements, and cannot be eliminated, and achieves the effect of solving the low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

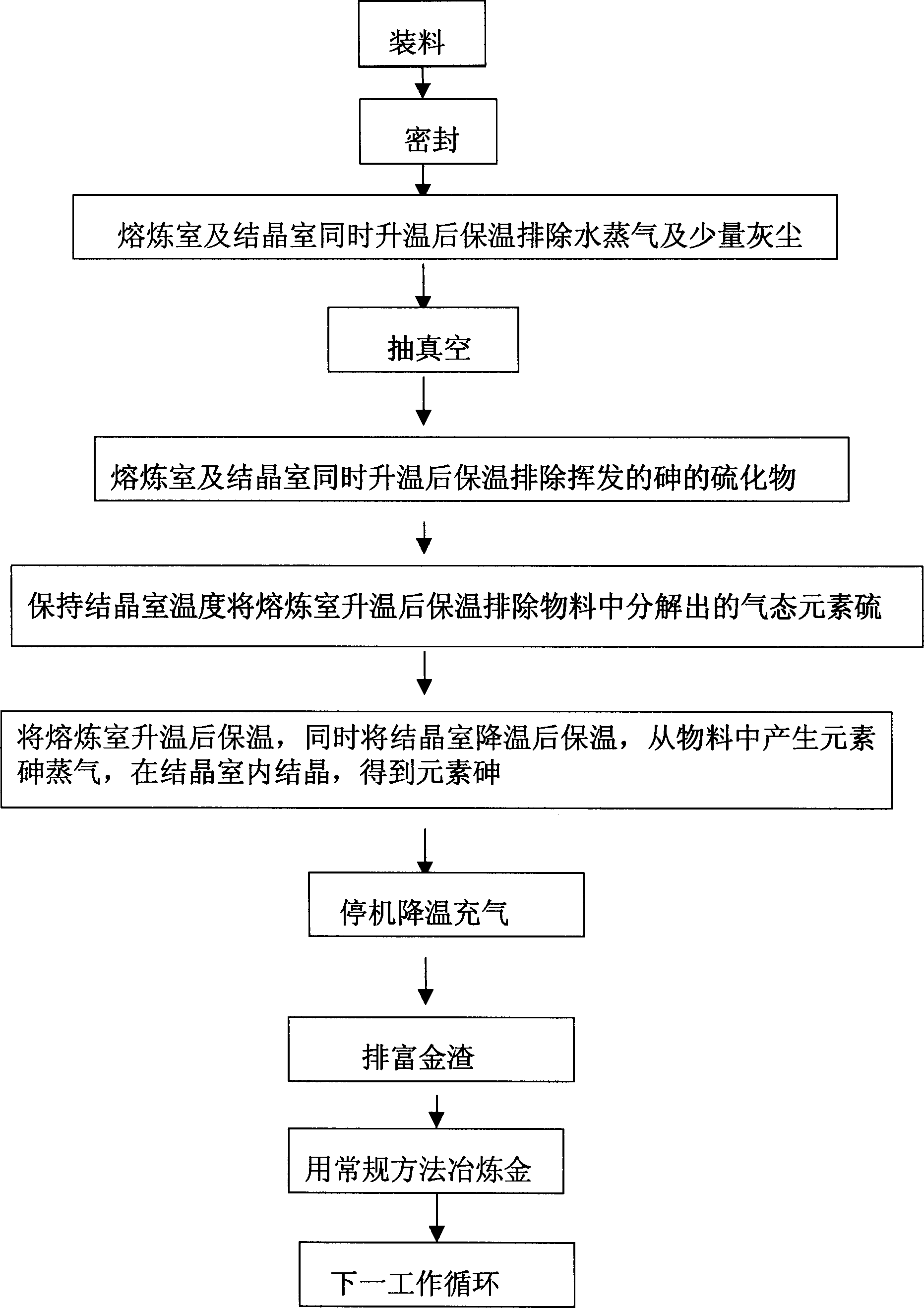

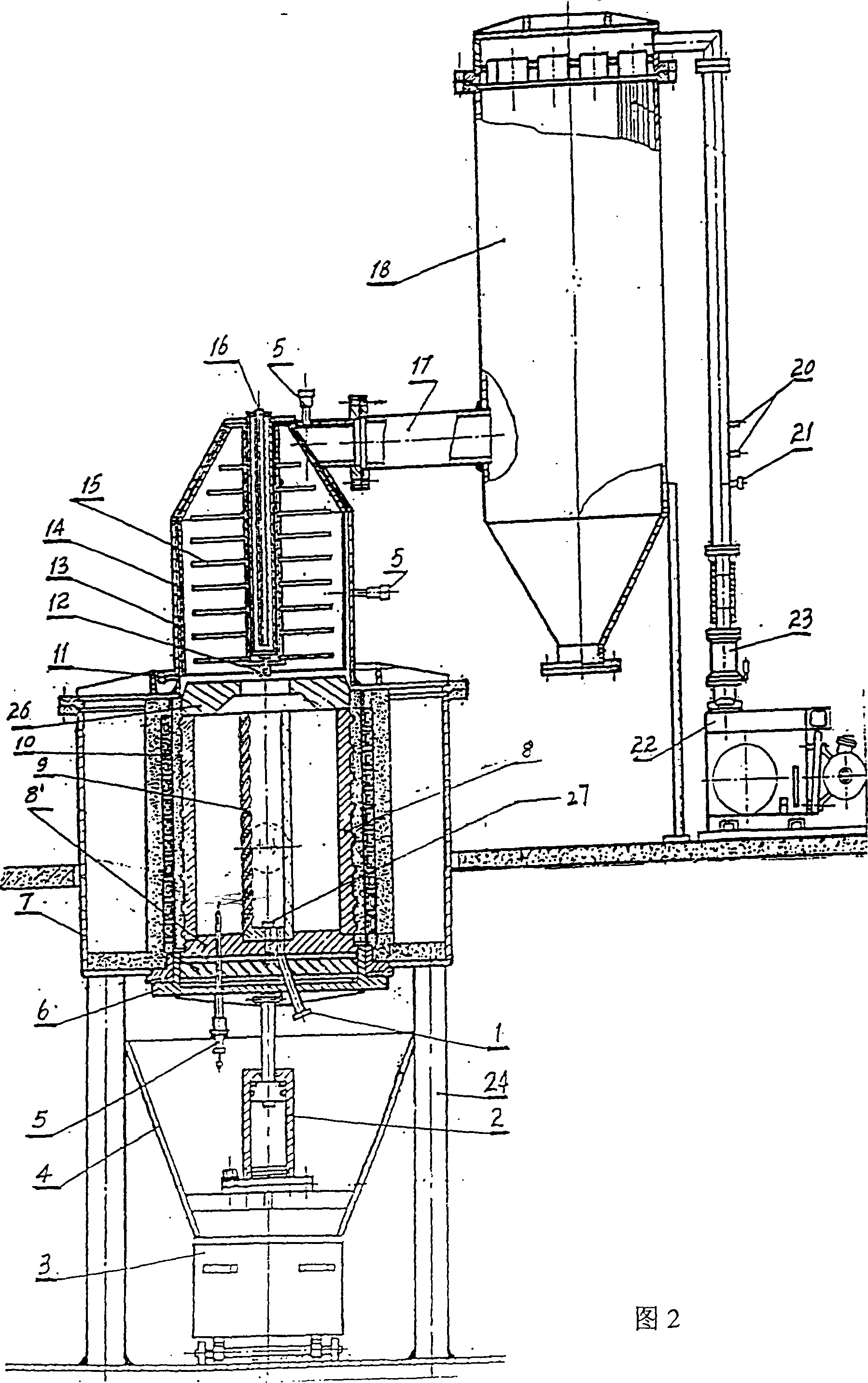

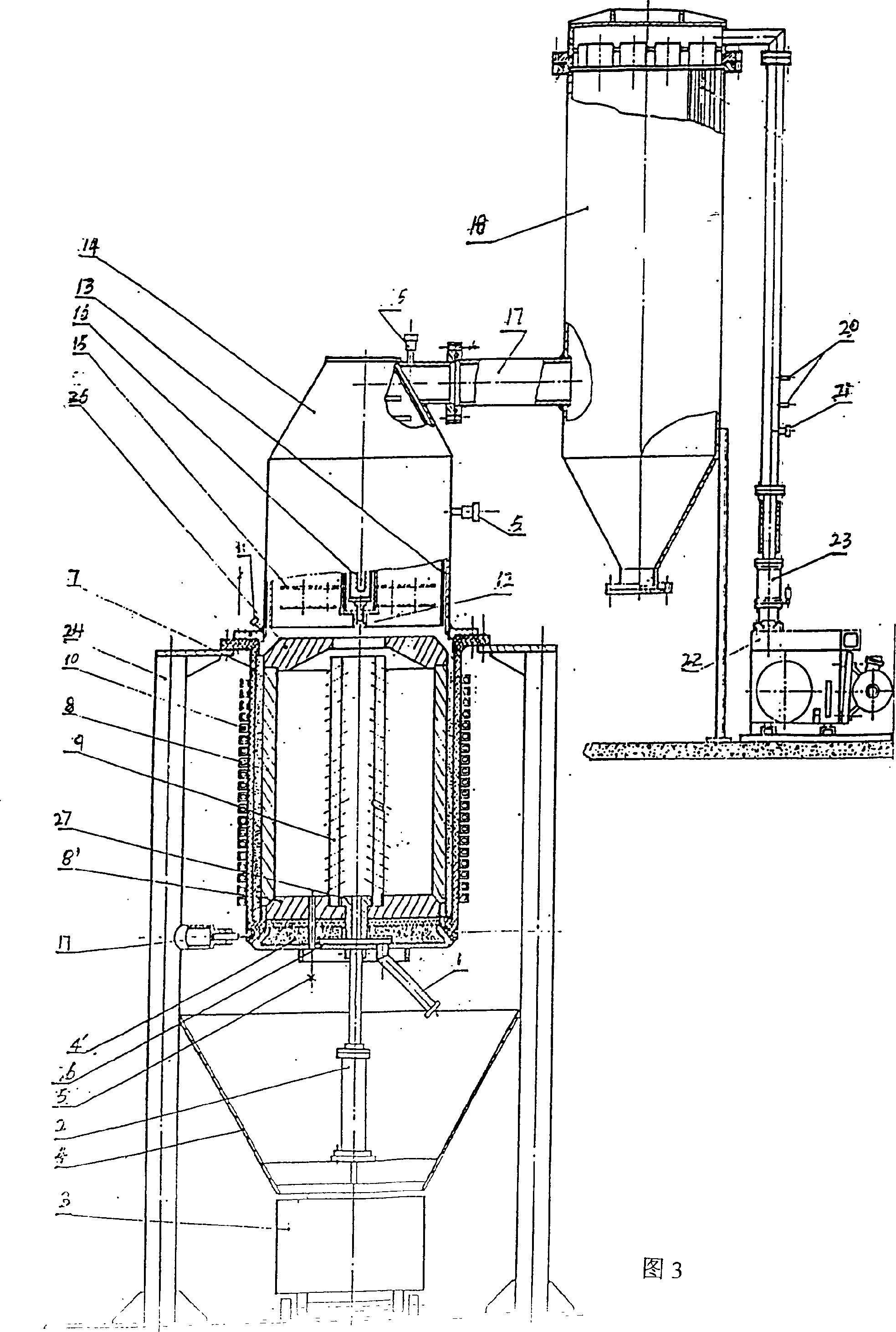

[0080] Please refer to the attached figure 1 The flow chart of the method for extracting gold from arsenic-containing gold concentrates, crushing 2.5 tons of arsenic-containing gold sulfide concentrates into a particle size of 1mm and putting them in a graphite crucible, adding 62 kg of scrap iron powder to fix the sulfur, so that Sulfur remains in the slag in the form of FeS, tighten the crystallization chamber installation nut 12, and start the intermediate frequency heating device. The experimental conditions are shown in Table [5]. In order to eliminate the water vapor and a small amount of dust in the arsenic-containing gold sulfide concentrate, the temperature was raised to 100°C and then kept for 2 hours. The water vapor generated in the concentrate and a small amount of dust gathered together In the multi-slant hole gathering and exhaust pipe 9 in the center, the water vapor discharge pipe 1 is connected to the exhaust fan simultaneously, so that water vapor and a smal...

Embodiment 2

[0084] Adopt the same experimental procedure of embodiment 1, the difference is to get rid of water vapor and a small amount of dust in the arsenic-containing gold sulfide concentrate, the temperature is raised to 150 ℃ and then kept for 2 hours; for getting rid of the arsenic-containing sulfide gold concentrate For the volatilized arsenic sulfide, the temperature of both the smelting chamber and the crystallization chamber was raised to 320°C and then kept for 2 hours; in order to eliminate the gaseous element sulfur decomposed from the arsenic-containing gold sulfide concentrate, the temperature of the crystallization chamber was lowered to 300°C ℃, raise the temperature of the smelting chamber to 530°C and keep it warm for 2 hours; in order to obtain the elemental arsenic in the arsenic-containing gold sulfide concentrate, keep the crystallization chamber at 300°C and keep it warm for 7 hours, then continue to raise the temperature of the smelting chamber to 630°C and keep it...

Embodiment 3

[0086] Adopt the same experimental procedure of embodiment 1, the difference is to get rid of water vapor and a small amount of dust in the arsenic-containing gold sulfide concentrate, the temperature is raised to 200 ℃ and then kept for 1.5 hours; for getting rid of the arsenic-containing sulfide gold concentrate For the volatilized arsenic sulfide in the medium, raise the temperature of the smelting chamber to 350°C, raise the temperature of the crystallization chamber to 300°C, and then keep it warm for 1.5 hours; in order to eliminate the gaseous element sulfur decomposed from the arsenic-containing gold sulfide concentrate, the The temperature of the crystallization chamber is raised to 320°C, and the temperature of the smelting chamber is raised to 570°C and then kept for 1.5 hours; in order to obtain the elemental arsenic in the arsenic-containing gold sulfide concentrate, the temperature of the crystallization chamber is lowered to 300°C and kept for 6 hours, and the sme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com