Method for leaching selenium and tellurium from waste anode copper slime and method for extracting selenium and tellurium

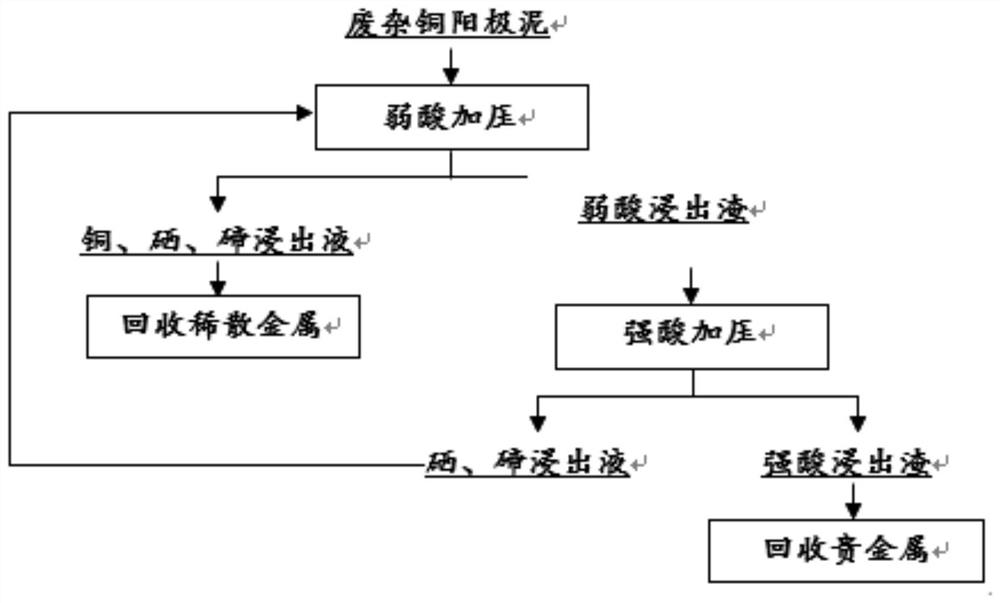

A technology of waste miscellaneous copper anode slime and anode copper, which is applied in the direction of elements such as selenium/tellurium, can solve the problems that the leaching rates of selenium and tellurium are difficult to balance, the leaching rate of tellurium is not high, and the leaching rate of selenium is not high, and the processing time is short, The process is simple and the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

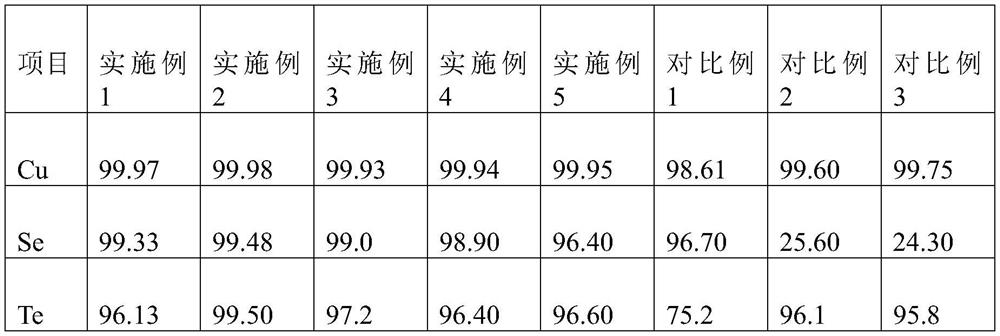

Embodiment 1

[0050] The method for leaching selenium and tellurium from waste miscellaneous anode copper slime provided by the present embodiment is specifically:

[0051] One-stage dilute acid leaching: Put the waste miscellaneous copper anode slime in an acid-resistant autoclave for one-stage dilute acid oxygen pressure leaching. The liquid-solid ratio is controlled at 10mL / g, the temperature is 150°C, the sulfuric acid concentration is 50g / L, It is 1.5Mpa, and the time is 2h. The first dilute acid leaching slag contains Cu, Se and Te respectively 0.40%, 1.14% and 0.94%.

[0052] Second-stage concentrated acid leaching: put the first-stage dilute acid leaching residue in an acid-resistant autoclave for two-stage concentrated acid oxygen pressure leaching. The liquid-solid ratio is controlled at 20mL / g, the temperature is 150°C, the sulfuric acid concentration is 90g / L, The partial pressure is 1.5Mpa, and the time is 2h. The secondary concentrated acid leaching slag contains 0.038%, 0.3...

Embodiment 2

[0054] The method for leaching selenium and tellurium from waste miscellaneous anode copper slime provided by the present embodiment is specifically:

[0055] One-stage dilute acid leaching: Put the waste miscellaneous copper anode slime in an acid-resistant autoclave for a stage of weak acid oxygen pressure leaching. The liquid-solid ratio is controlled at 12.5mL / g, the temperature is 160°C, the sulfuric acid concentration is 40g / L, 1.6Mpa, time 3h, a weak acid leaching slag containing Cu, Se, Te were 0.45%, 1.25%, 0.75%.

[0056] Two-stage concentrated acid leaching: put the leaching residue of one stage of weak acid in an acid-resistant autoclave for two-stage strong acid oxygen pressure leaching. 1.6Mpa, time 3h, secondary strong acid leaching slag contains Cu, Se, Te respectively 0.016%, 0.28%, 0.12%.

Embodiment 3

[0058] The method for leaching selenium and tellurium from waste miscellaneous anode copper slime provided by the present embodiment is specifically:

[0059] One-stage dilute acid leaching: Put the waste miscellaneous copper anode slime in an acid-resistant autoclave for one-stage dilute acid oxygen pressure leaching. The liquid-solid ratio is controlled at 10mL / g, the temperature is 135°C, the sulfuric acid concentration is 60g / L, It is 1.25Mpa, and the time is 4h. The first dilute acid leaching slag contains 0.59%, 1.35%, and 1.01% of Cu, Se, and Te, respectively.

[0060] Two-stage concentrated acid leaching: put the one-stage dilute acid leaching residue in an acid-resistant autoclave for two-stage concentrated acid oxygen pressure leaching, control the liquid-solid ratio to 15mL / g, the temperature is 135°C, the sulfuric acid concentration is 120g / L, The partial pressure is 1.25Mpa, and the time is 4h. The secondary concentrated acid leaching slag contains 0.05%, 0.34%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com