A kind of copper ore associated molybdenum sorting method

A technology for copper ores and minerals, which is applied in the field of separation of molybdenum metal minerals associated with copper ores, can solve the problems of increasing S-Mo section ratio, decreasing floatability, affecting the recovery rate of molybdenum minerals, etc., and achieving a high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] Copper ore associated molybdenum sorting method of the present invention, its preferred embodiment is:

[0014] Include steps:

[0015] A. When the copper-sulfur rough concentrate containing molybdenum minerals obtained in the copper ore roughing process is used for copper-sulfur separation, the molybdenum minerals in the copper-sulfur rough concentrate are suppressed in the tailings of copper-sulfur separation operations, forming Tailings of molybdenum minerals;

[0016] B. After dehydration and chemical removal of copper-sulfur separation tailings containing molybdenum minerals, acid is added to adjust the pH of the tailings, sulfur and molybdenum agents are added, sulfur and molybdenum are selected, and a qualified sulfur containing molybdenum minerals is obtained. Concentrate;

[0017] C. Molybdenum-sulfur separation operation is carried out on qualified sulfur concentrates containing molybdenum minerals. Molybdenum-sulfur separation operations need to add inhibit...

specific Embodiment

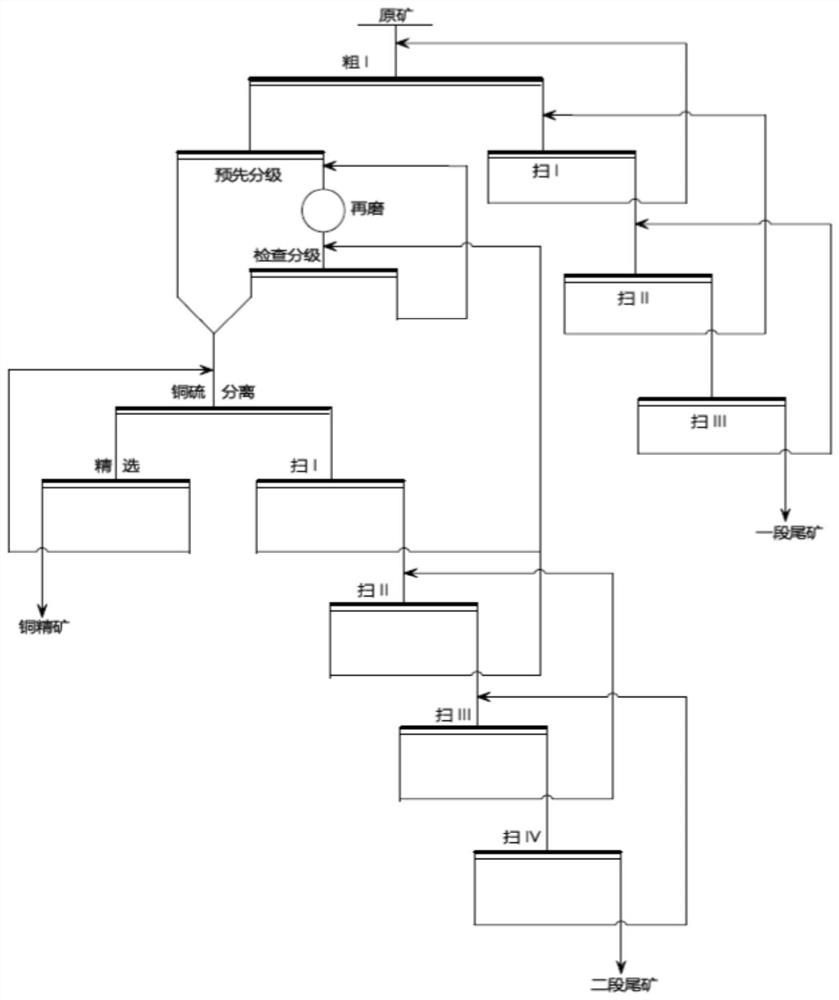

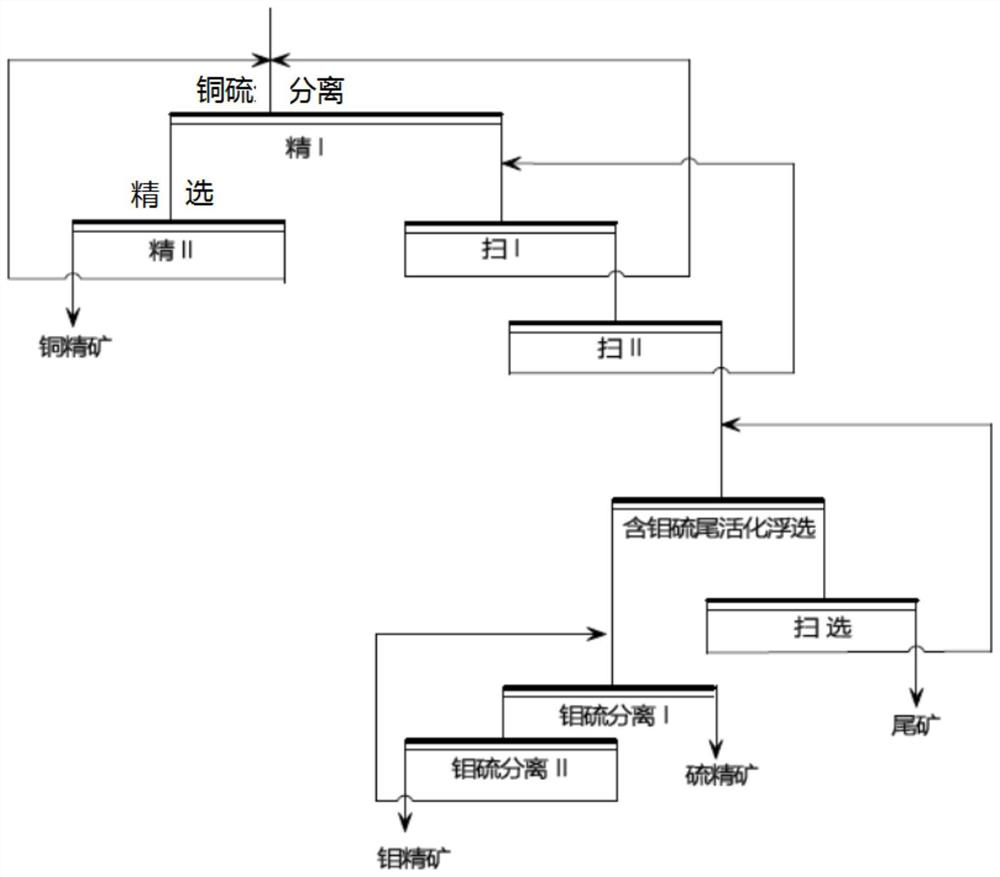

[0033] Such as figure 1 Shown is an industrial flow chart of a certain copper mine in Jiangxi. According to the industrial process and field indicators of a certain copper mine (associated molybdenum) in Jiangxi shown in the figure, specifically, the method may include the following steps:

[0034] The principle flow of reverse flotation-concentrated tailings activated concentrating-molybdenum-sulfur separation in the second stage copper-sulfur separation of a certain copper mine concentrator. It can be seen from the flow chart that in the current process, in the second-stage copper-sulfur separation operation, a large amount of molybdenum minerals are circulated in the copper fine tail to the rough separation of copper and sulfur. The current actual indicators on the site show that a large amount of molybdenum (molybdenum minerals 163.99%) in this operation cycle, under the action of lime, the molybdenum minerals are finally suppressed and lost in the tailings, so that the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com