A kind of fracturing production method of high waxy oil layer

A production method and oil layer technology, which are applied in the fields of production fluids, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of low recovery rate of heavy oil reservoirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The fracturing method of the high waxy oil layer of the present embodiment comprises the following steps:

[0079] (1) Well selection

[0080] Select the Ebi 1 well with the following characteristics:

[0081] A. The straight-line spacing between the production well and the steam-injected well that provides driving energy for production is 149m.

[0082] B. In the last cycle of the oil well, the boring time before the well was opened for production was 38 days, the production cycle before production was 29 days, and the daily oil production was 0.9 tons / day.

[0083] C. The well deviation of the oil well ranges from the kickoff point to the target layer after drilling, and the deviation of the oil well is 41°.

[0084] The reservoir and crude oil corresponding to the selected oil well have the following characteristics:

[0085] a. Reservoir thickness 1m, porosity 10%, permeability 9μm 2 , Oil saturation 31%;

[0086] b. The oil layer temperature is 80°C;

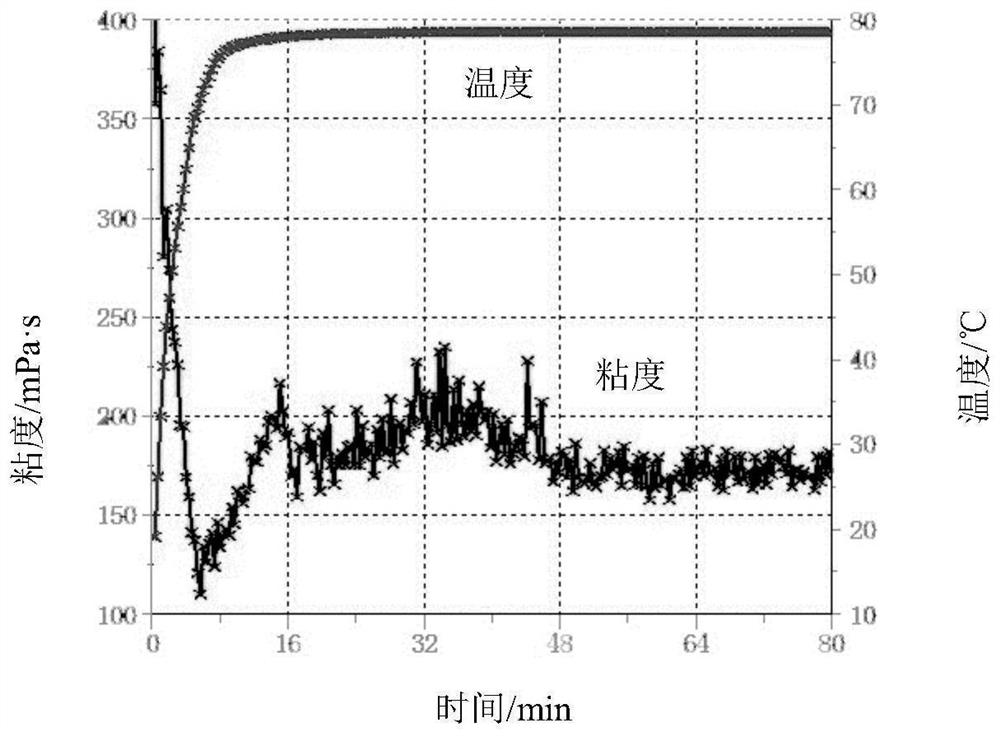

[0087]...

Embodiment 2

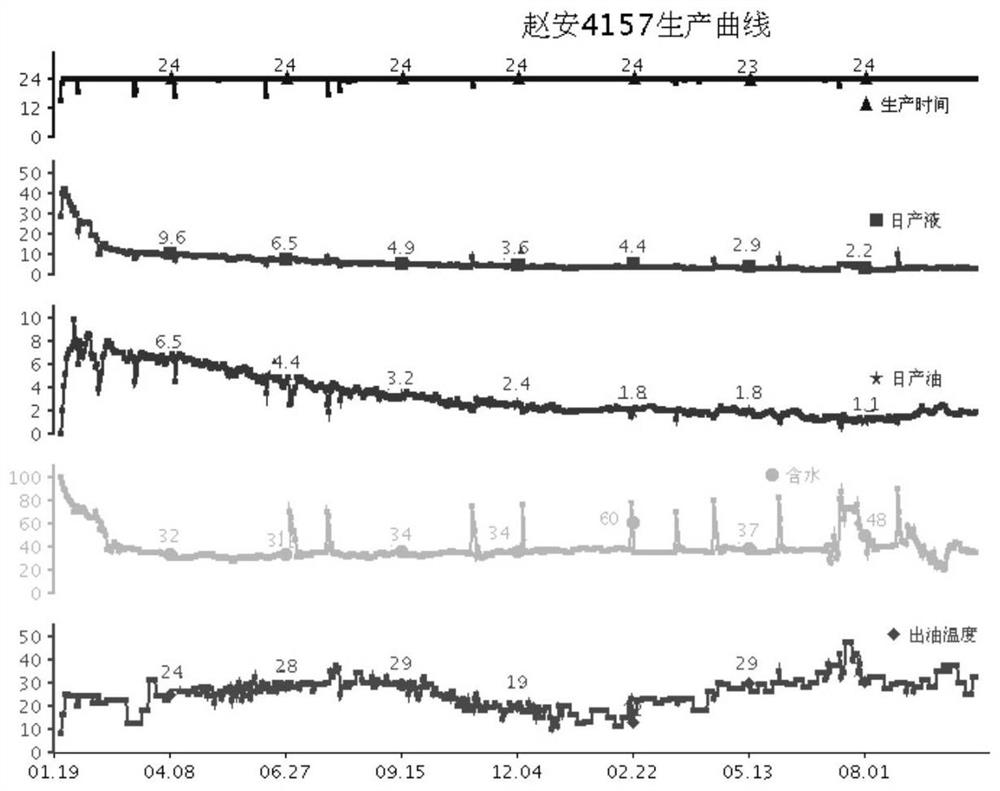

[0124] The fracturing method of the high waxy oil layer of the present embodiment comprises the following steps:

[0125] (1) Well selection

[0126] Select Well Wang 12 with the following characteristics:

[0127] A. The linear spacing between the production well and the steam-injected well that provides driving energy for production is 120m.

[0128] B. In the last cycle of the oil well, the boring time before the well was opened for production was 49 days, the production cycle before production was 22 days, and the daily oil production was 0.8 tons / day.

[0129] C. The well deviation of the oil well is within the range from the kickoff point to the target layer after drilling, and the deviation of the oil well is 55°.

[0130] The reservoir and crude oil corresponding to the selected oil well have the following characteristics:

[0131] a. Reservoir thickness 2m, porosity 8%, permeability 8μm 2 , Oil saturation 33%;

[0132] b. The oil layer temperature is 70°C;

[01...

Embodiment 3

[0167] The fracturing method of the high waxy oil layer of the present embodiment comprises the following steps:

[0168] (1) Well selection

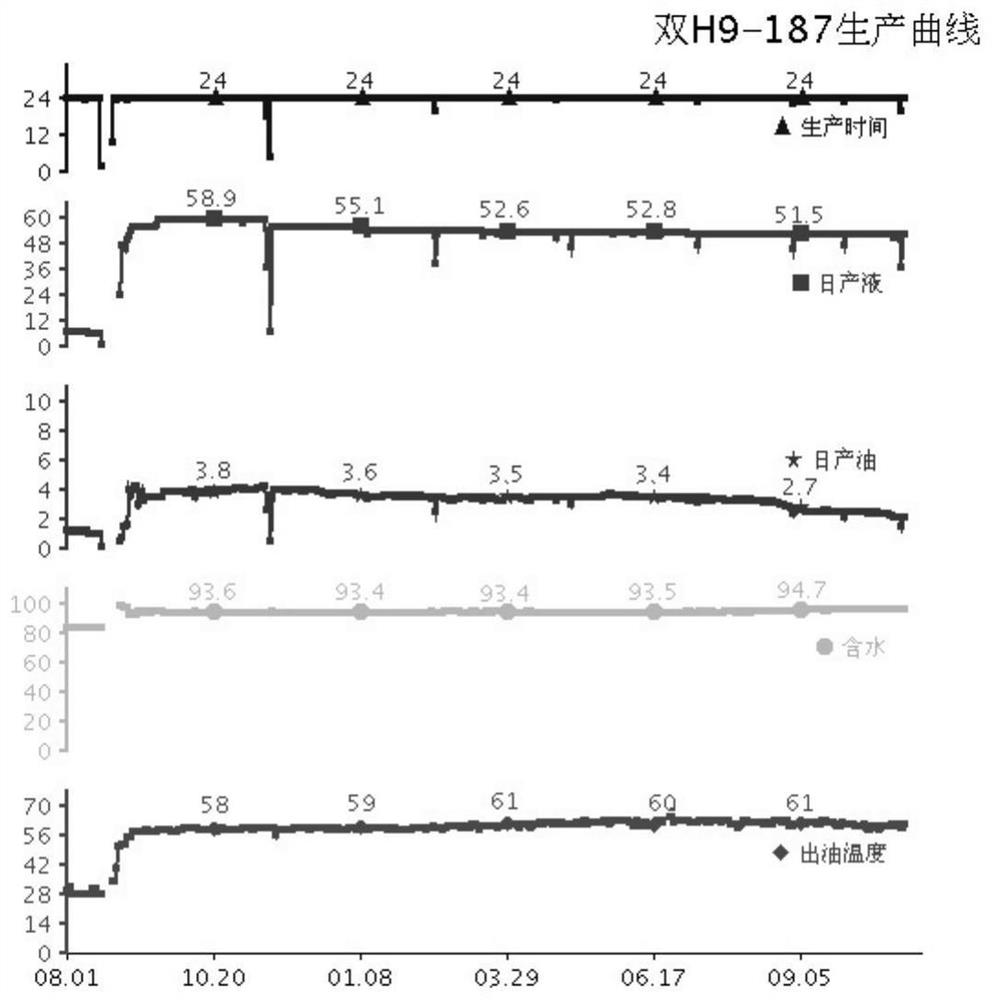

[0169] Select double H9-187 wells with the following characteristics:

[0170] A. The linear spacing between the production well and the steam-injected well that provides driving energy for production is 89m.

[0171] B. The boring time of the oil well in the last cycle before production was 67 days, the production cycle before production was 20 days, and the daily oil production was 0.5 tons / day.

[0172] C. The inclination of the oil well is within the range from the kickoff point to the target layer after drilling, and the inclination of the oil well is 61°.

[0173] The reservoir and crude oil corresponding to the selected oil well have the following characteristics:

[0174] a. The thickness of the oil layer is 5m, the porosity is 6%, and the permeability is 7μm 2 , The oil saturation is 35%;

[0175] b. The oil layer temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com