Indoor sound insulation structure

A technology of structure and door leaf, which is applied in the direction of sound insulation, building structure, insulation layer, etc., can solve the problems of high overall cost of indoor sound insulation structure, complicated manufacturing process, and high production cost, so as to achieve stable structure of airtight room and reduce production The effect of reducing cost and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

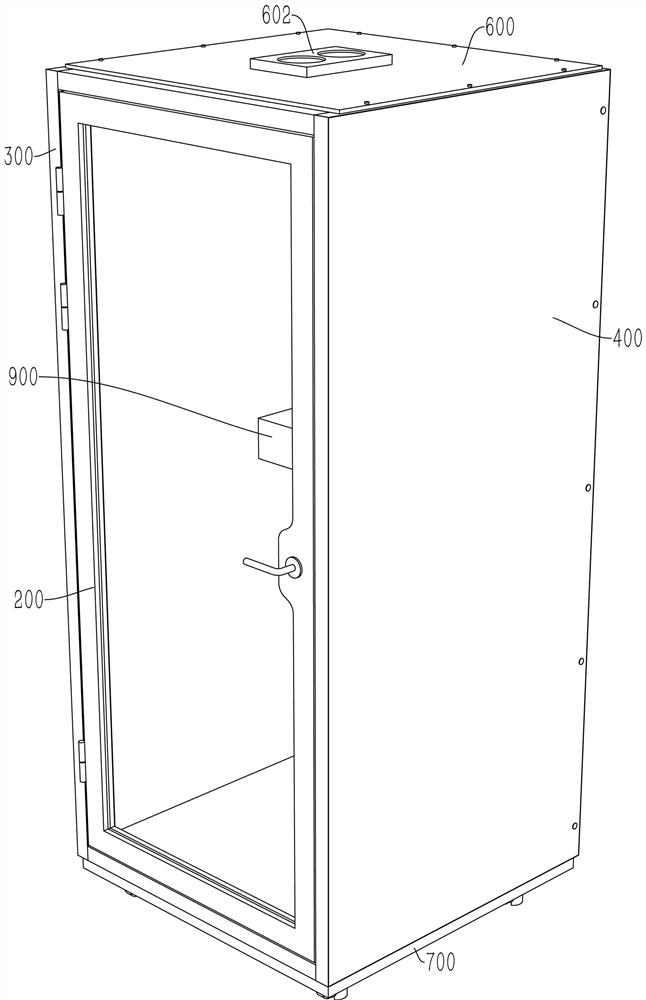

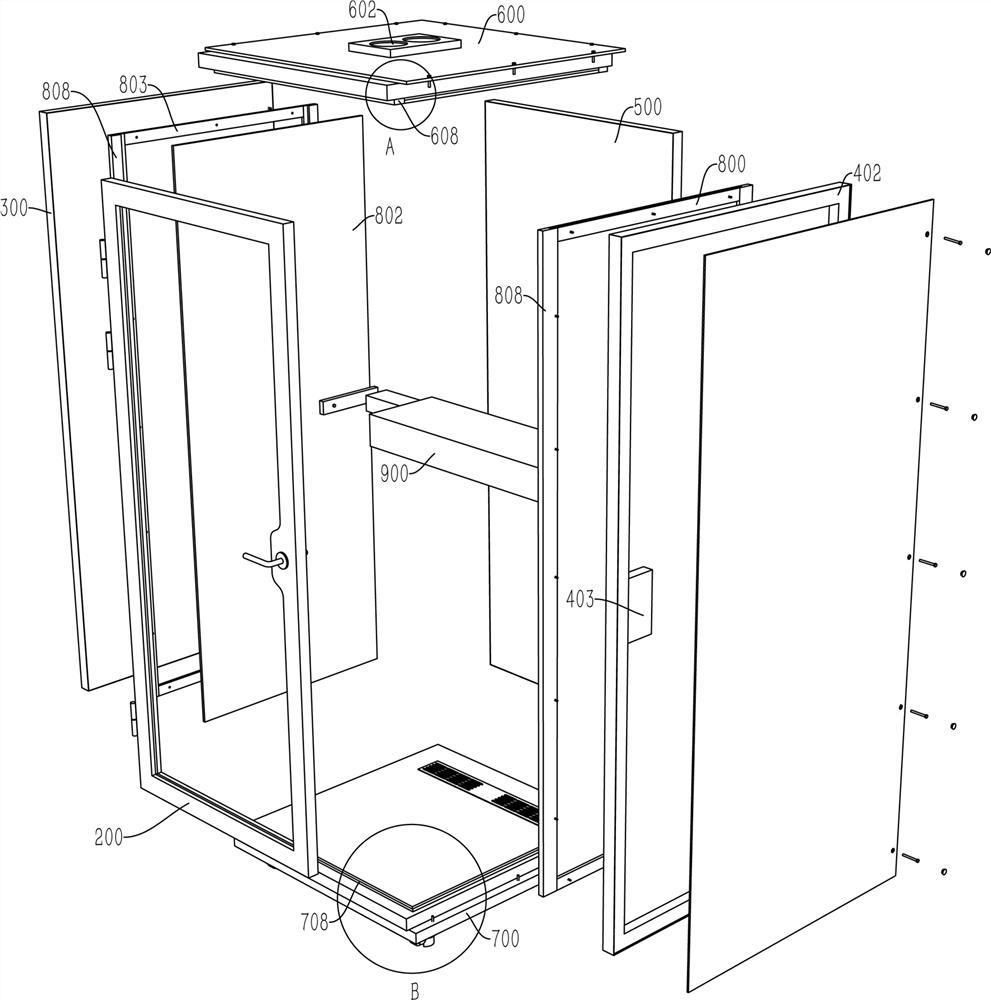

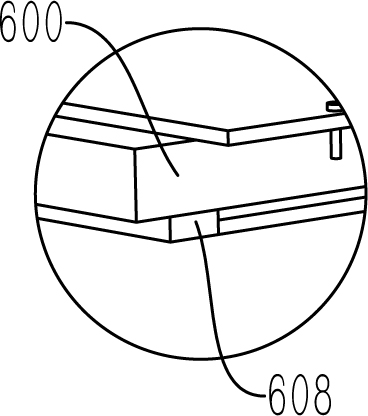

[0032] Embodiments of the present invention are as Figures 1 to 6 As shown, an indoor sound insulation structure includes a wall assembly, a door assembly 200, a top assembly 600, and a bottom assembly 700. A door leaf is used as a wall assembly. The door leaf includes a door leaf frame and a door panel, and the door leaf frame is connected with other door leaf frames, The door assembly, the top assembly and the bottom assembly are connected, and the door leaf frames are connected to each other and the door assembly, the top assembly, the bottom assembly and the door leaf frame are connected by bolts.

[0033] Wherein, the left door leaf 300, the right door leaf 400 and the rear door leaf 500 together constitute a wall assembly. like figure 2 As shown, the right door leaf 400 includes a right door leaf frame 402 and a right door lock wood 403 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com