Buoyancy self-control type inverted siphon and construction process thereof

An inverted siphon and buoyancy technology, which is applied in the field of pipelines, can solve the problems of high operation difficulty, inconvenience for construction personnel, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

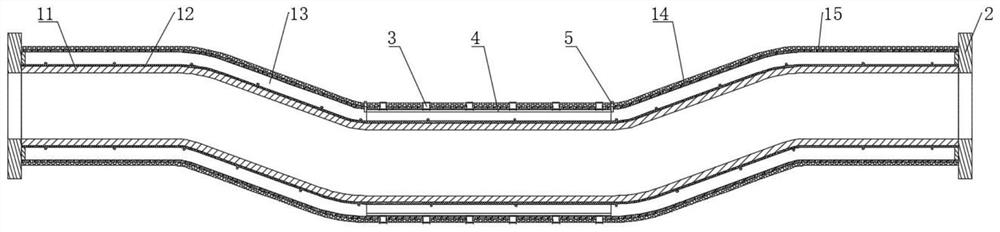

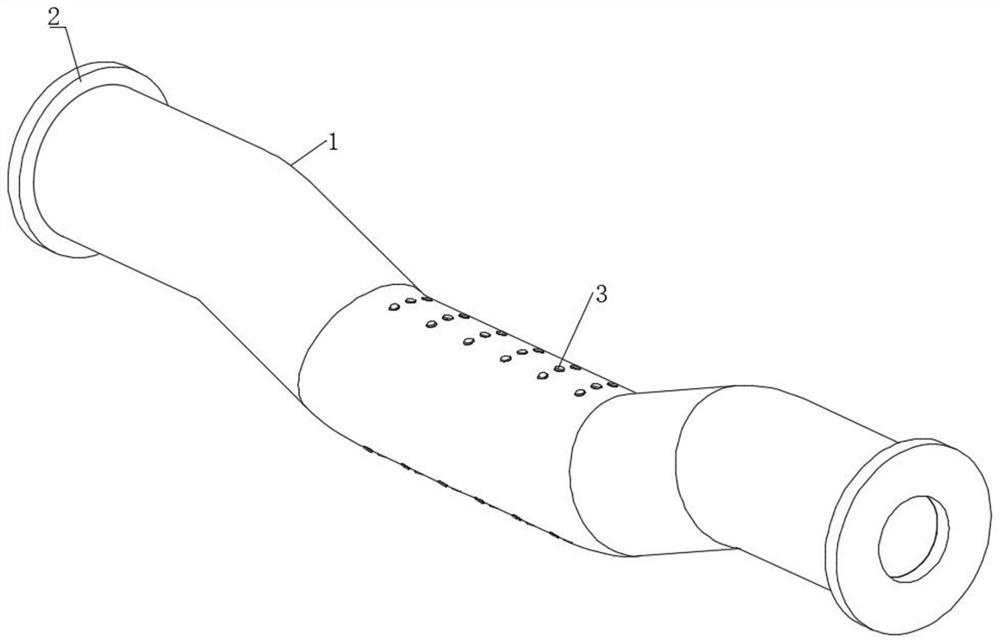

[0053] see Figure 1-8 , a buoyancy self-control type inverted siphon, comprising a pipeline body 1, the pipeline body 1 includes a pipeline support body 11, the outer end of the pipeline support body 11 is coated with a pipeline protective interlayer 12, and the outer end of the pipeline protective interlayer 12 is fixedly connected with Vacuum suction cavity 13, the outer end of the vacuum suction cavity 13 is fixedly connected with a water-proof protective layer 14, the outer end of the water-proof protective layer 14 is fixedly connected with a pipeline outer protective layer 15, and the upper and lower ends of the pipeline outer protective layer 15 are fixedly connected with multiple The water filling joint 3, the inner end of the water filling joint 3 runs through the water-proof protective layer 14, and is connected with the vacuum water suction chamber 13, and the sealing sleeve 4 matched with the water filling joint 3 is rotatably connected in the vacuum water suction ...

Embodiment 2

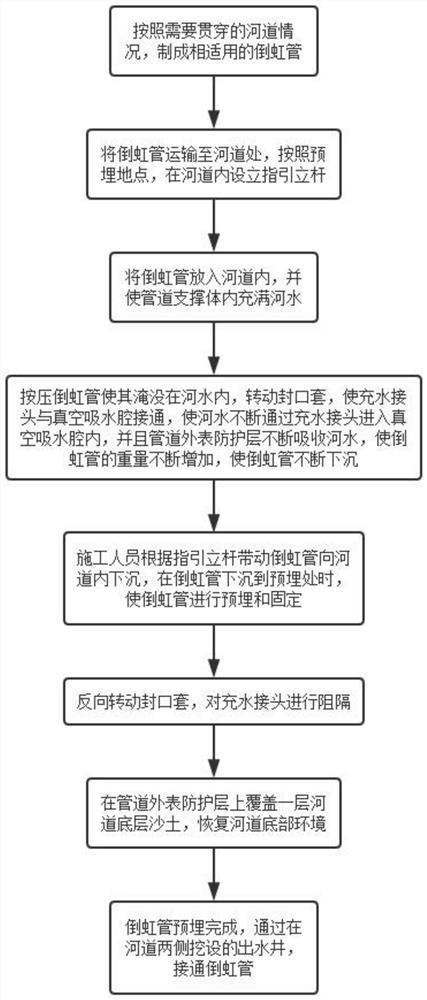

[0064] see Figure 1-8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , a construction technique for a buoyancy self-control type inverted siphon, comprising the steps of:

[0065] S1. Make a suitable inverted siphon according to the conditions of the river that needs to run through;

[0066] S2. Transport the inverted siphon to the river, and set up a guide pole in the river according to the pre-buried location;

[0067] S3. Put the inverted siphon into the river channel, and fill the pipe support body 11 with river water;

[0068] S4. Press down the siphon to make it submerged in the river water, turn the sealing sleeve 4 to connect the water filling joint 3 with the vacuum water suction chamber 13, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com